|

| |

Product Classification : Can Making----Aerosol Can Testing

|

| Total page:1

Current page:1 Total records:28 |

First | Previous | Next | Last

|

|

|

CanNeed-ZM-10 Portable Digital Body Blank Gauge

|

|

The “CanNeed ZM-10 Digital Body Blank Gauge” is made for the quality control of can body blanks. It is a precision gauge for body blank measurement/angle measurement. It’s particularly suitable for the production line inspection after the adjustment.

Adopting aluminum alloy material so that it is quite light and convenient.

|

|

|

CanNeed-WWP-100 Welding Seam Ball Press Tester

|

|

The “CanNeed-WWP-100 Welding Seam Ball Press Tester” is used to test the welding seam quality, including the welding seam strength and continuity of 3-piece cans.

Testing Method: place the empty cans to the clamp, align the welding seam with the ball, and then tightly press the can. The cylinder pushes the ball to slide along the welding seam. Next, take the can out to check if there are any breaches.

|

|

|

Seam-X-Line X-Ray Automatic Seam Scanner (Non-destructive)

|

|

Seam-X®-Line Automatic Seam Scanner adopts non-destructive measurement method to measure the seam quality, suitable for measuring the aluminium cans, steel cans , aluminium-iron composite cans and etc. If configured with the conveyor, it can achieve automatic sampling from the production line. It's applicable for laboratory or producing department.

|

|

|

SeamSight®-B Full Automatic Seam System

|

|

The CanNeed Seam Sight® Full Automatic Seam Monitor has adopted the advanced optical system and Golden Lens® video capture device, which interference-free of external light source and ensured the high image definition and the measurement accuracy. The Seam Sight® system is equipped with the new seam measuring software Seam Sight®.

The CanNeed Seam Sight® -A system can automatically collect the data from STG-200-D Seam Thickness Gauge and CSG-200 Countersink Gauge. The actual seam thickness and countersink can be generated reports together with other data. To optimize the measurement process.

Measurement Process

Before cutting the sample can, use STG-200-D Seam Thickness Gauge to measure the seam thickness rate; meanwhile, use CSG-200 Countersink Gauge to measure the countersink rate; then the Seam Sight -A will collect the both data automatically.

After that, the sample can should be cut with CSS-1000 Anti-noise Seam Saw or CSS-2000 Seam Saw and placed at the camera position of the monitor. Then, the seaming images will be displayed on the screen. The auto measurement will be finished within 1 second if you press the “Confirmation” button. All images and measurement data will be saved in the system data base.

|

|

|

CSS 2000 Seam Saw

|

The CanNeed CSS-2000 Seam Saw is applicable for all types of cans of 45-260mm. The movable cutting platform is installed on the linear guide.

The CanNeed “CSS-2000 Seam saw” is a special seam circular saw with double cut for double seam inspections. The CSS-2000 was specially designed for 2- and 3-piece cans.The nitrated blades achieve together with the speed of approx. 1.000 r/min. a very plain cut surface. The seam image on Caneed series Automatic Seam Computer (Video Seam Monitors), and automatic seam measuring systems gets thereby very clear and improves measurement speed and reliability.

|

|

|

CanNeed-ACH-100 Aerosol Curl Height Gauge

|

|

CaNneed-ACH-100 Aerosol Curl Height Gauge is used for measuring the contact height of the curl 1” aperture of aerosol cans. ACH-100 is the Industry Standard.

|

|

|

SCG-200 Seamer clearance Gauge

|

The CanNeed SCG-200 Seamer clearance Gauge, a quick and accurate way to set up seamers.To measure the roll height off the chuck and the lateral distance between the roll and chuck.

The Clearance Gauge allows users to do predictive maintenance on their seamers before they go out of specifications. The clearance gauge is able to not only quickly and accurately set up the seamer, but makes sure that all the seamer heads are performing perfectly as near as possible to the nominal value.

Instead of focusing on checking seams after the double seam is already closed, the Clearance Gauge helps optimize the can seaming process by taking out variations between the different seamer heads and optimizing the seamer itself!

Today, covering most seamer models, these seamers show a clear and dramatic performance improvements by using this gauge.

|

|

|

CanNeed-ABT-200 Burst Buckling Tester for aerosol cans

|

Aerosol can manufacturers need not only to save cost but also to ensure product quality, they are in a great need about devices which can accurately measure and assess the performance of the aerosol cans.

CanNeed-ABT-200 Burst Buckling Tester for Aerosol Cans is used for testing the buckle value of bottom and end (dome) of aerosol cans and the pressure at which the can bursts.

|

|

|

RPG-100 Roll profile Gauge

|

|

The RPG-100 is able to scan profiles of seaming Rolls and Chucks (or other tooling - including carbide and ceramic tools) easily and quickly. The system can be used for acceptance testing for new seaming rolls or chucks, for quality assurance purposes and for stress analysis. Monitor tooling wear to replace rolls and chucks only when they need to be replaced

|

|

|

CanNeed-ABT-100 Burst Buckling Tester for Aerosol Cans

|

|

CanNeed-ABT-100 Burst Buckling Tester for Aerosol Cans is used to determine the buckle value of bottom (dome) and Top end of aerosol cans and the pressure at which the can bursts. With the special designed clamp, it is able to measure the dome or bottom free ends independently. At high pressures from approximately 22 - 28 bars, it may happen that deformations of the valve and a higher burst pressure.

|

|

|

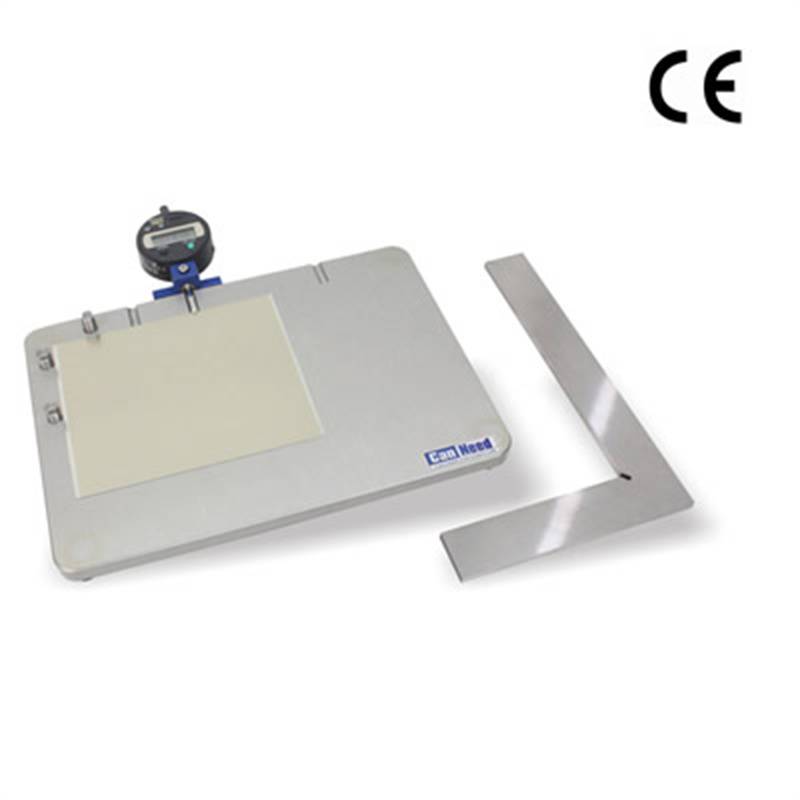

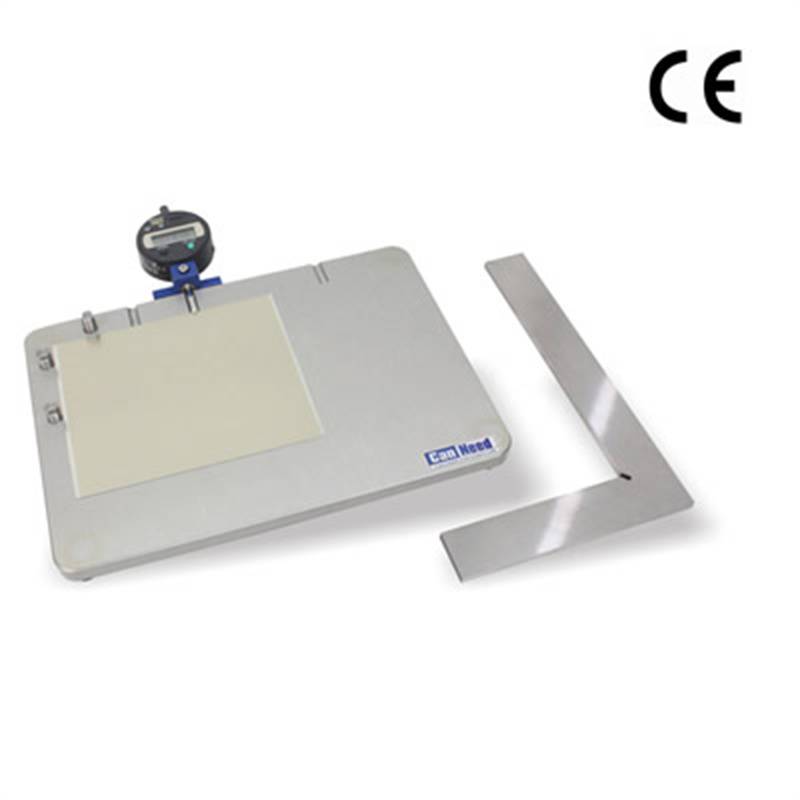

ZM570-D Digital Body Blank Gauge

|

|

Canneed "ZM570-D Digital Body Blank Gauge"

These units are made for the quality control of can body blanks.

1. Precision gauge for measurement of body blanks with the help

of a incremental ruler/ fine measuring gauge combination and

a digital dial indicator for the angle measurement;

2. Constant measuring force for accurate, repeatable,

user-independent results

3. Sequential measurement of blank height, blank width and squareness

|

|

|

CanNeed-DER-4 Digital Enamel Rater

|

|

The CanNeed-DER-4Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

CanNeed-DER-4 is the industry standard. The new CanNeed-DER-4Enamel Rater instrument test the coverage of the enamel coating inside food and beverage cans, aerosol-cans and also different kinds of ends. It displays an index of the amount of metal exposed by incomplete enamel coverage on a clear, easily read digital LED.

|

|

|

CanNeed-ALT-100 Leak Tester for Aerosol can

|

|

CanNeed-ALT-100 Leak Tester for Aerosol can is used for testing the leakage of Aerosol cans in a water bath. The can is freely suspended and submerged into the water. At the same time it is subjected to pressure and leaks are revealed by air bubbles. Test pressure 8 - 10 bar. The test procedure is performed semi-automatically. The tester is suitable for all aerosol can diameters. The maximum can height is 300 mm.

|

|

|

ALT-600 Leak Tester for Aerosol can

|

|

The “Canneed ALT-600 / ALT-800 Leak Tester for Aerosol can” is used for testing the leakage of Aerosol cans. ALT-600 can test 6 cans at the same time, and ALT-800 can test 8. The permeability tester for aerosol cans blows up the cans up to a maximum of 10 bar and submerges them under water. At the leaking spots of the can then visible air-bubbles escape.

A special clamping system enables to measure different diameters and heights with one device. Two pressure levels can be set with the tester. The first is meant to hold and seal the can, the second step sets in when the mount with the cans has reached the lowest position. The maximum test pressure is 10 bar.

|

|

|

CanNeed-CND-TRK-300 Oven Temperature Tracker

|

|

The “CanNeed-TRK-300 Oven Temperature Tracker” is a professional oven temperature curve inspection system for the coating industry, it is including the data logger, heat insulation case, software (Chinese / English) and thermocouples.

"CanNeed-TRK-300 Oven Temperature Tracker” is use to pass through the oven with the solidifying products, and record down the real temperature during the process. The logger is in the centre of the system. Heat insulation case is for protecting the logger from over heat by the oven. When passing through the oven, the CanNeed-TRK-300 Oven Temperature Tracker will record down the real time temperature of the solidifying products through the 5 thermocouples which were connected to the products, and one thermocouple is for recording the air temperature of the oven. After the recording process was finished, use the CND_TRK Software to analyze the temperature data and generate the detail reports.

|

|

|

FWG-100-D, FWG-200-D, FWG-300-D Flange Width Gauge

|

|

The “CanNeed-FWG-100-d, CanNeed-FWG-200-d, CanNeed-FWG-300-d Flange Width Gauge (digital)” is used to measure the flange width of empty cans. Reliable design, invariableness measuring pressure and measuring angle which enable the inexperienced operators can also perform the measurement accurately. Auto aligning the center of can body, applicable for different types of cans.

If purchased the adapter and cable, the gauges can be connected to a computer or SPC system for data collection, avoiding the manual recording and personal error.

|

|

|

CanNeed-STR-100A Seam Stripper

|

The automatic “CanNeed-STR-100 Seam Stripper” is a sensible, affordable, teardown method to prepare the double seam teardown analysis. One fast, safe teardown operation without damaging or distorting the cover hook. Reduce teardown time for more frequent inspections. Tooling quick change in few seconds. Models are available for most common can sizes of beverage and food cans. When ordering, the end diameter and can height must be specified so that the appropriate change parts are included. Efficient cut and strip both aluminium and steel cans in a single motion. 10 seconds per can. Eliminates the repetitious actions by hand.

An important part of any seam evaluation is the actual teardown of the can seam to determine tightness or wrinkled rating.

|

|

|

CanNeed-CSG-A Countersink Gauge for Aerosol Cans (digital)

|

|

CanNeed-CSG-A Countersink Gauge (digital) is a digital gauge for measuring countersink depth parameters of aerosol cans. Equipped with Zero-Adjusting calibration platform and protection piece.

If purchased the adapter and cable, the gauge can be connected to a computer or SPC system for data collection, avoiding that the persons record the data. It can also used together with the seam sight monitor and output the measuring data to the PC.

|

|

|

CanNeed-DHG-300 Digital Can Height Gauge

|

|

The "DHG-300 Digital Can Height Gauge" can be used to measure the height of beverage, food, and aerosol cans. The gauges can be connected to a computer or SPC system via the adapter and cable.

|

|

|

CSM-207 Can Seam Micrometers

|

CanNeed CSM series Can Seam Micrometers are use for measuring the seam thickness and length. The fine tuning function helps to avoid the deviation caused by over rotation.

CSM-208 is applicable to measure the seam thickness and length of flat bottom straight wall cans.

CSM-207 is applicable to measure the seam thickness and length of aerosol cans and necked-in cans.

|

|

|

CanNeed-CAN-10774 Planer and Shaper Pin Height Gauge

|

|

CanNeed-CAN-10774 The Pin Height Gauge is commonly used in the initial setup of the seamer to ensure double seaming

performance and air removal.

All working surfaces are hardened and accurately ground.

|

|

|

CAN-1050 Can Closing Force Gauges

|

"CAN-1050 Can Closing Force Gauge" is for measuring the force of seaming head of the seaming machine. Advantages:

1. Deduct the scrap rate of the production

2. Shorten the adjusting time, improved production efficiency.

3. Improved the seam quality

|

|

|

CanNeed-IDG-100/200/300 Can Internal Diameter Gauge

|

|

The “CanNeed-IDG-100 Internal Diameter of Can” is used to measure the internal diameter of small cans, such as 200, 202, 206, 209.

The “CanNeed-IDG-200 Internal Diameter of Can” is used to measure the internal diameter of larger cans. According to clients’ request, CanNeed-IDG-200 can be made to measure 2 to 3 different sizes of cans at the most at the same time. Note: The difference between the internal diameters of the two cans must be over 10mm.

When placing the order, please indicate the internal diameters of the cans, such as 202 neck-in cans, 206 neck-in cans.

With the Mitutoyo 0.01mm resolution digital indicator.

If purchased the adapter and cable, the gauge can be connected to a computer or SPC system for data collection.

|

|

|

CanNeed-PTG-100 Digital Plate Thickness Gauge

|

This unit serves for quickly checking the thickness of plates. The sample is presented vertically in this version. Equipped with the Mitutoyo 0.001mm Resolution Digital Indicator.

If purchased the adapter and cable, the gauge can be connected to a computer or SPC system for data collection.

|

|

|

CDG-100 Curl Diameter Gauge

|

The CanNeed "CDG-100 Curl Diameter Gauge" is a Digital gauges for measuring Curl Diameter of ends. Equipped with calibration piece. With the Mitutoyo 0.01mm Resolution Digital Indicator.

If purchased the adapter and cable, the gauge can be connected to a computer or SPC system for data collection.

|

|

|

WOM 4C Welding Overlap Monitor

|

|

The CanNeed “WOM 3A Welding Overlap Monitor” is used to measure the length and thickness of side seam welding overlap. It’s equipped with the most advanced optical system and Golden LensTM, which ensured the high image definition.

|

|

|

CanNeed-WWT-100 Welding Line Outstretched Tester

|

|

The “CanNeed-WWT-100 Welding line outstretched tester” is used to test the flange point welding integrality of 3-pieces cans.

How to test: Place a sample can body on the corresponding plug, handle piston valve. And the cylinder drives the board to press the can body. Stop when the flange os curled about 10 mm. Then loosen the piston valve, take the can body out to check if there is any breaches. Mark down the result.

|

|

|

VSM 6A Automatic Seam Monitor

|

The " VSM 6A Automatic Seam Monitor " is a compact measuring system

for quick and accurate automatic seam measurements and storing of seam images.

The seam length, body hook, end hook, actual overlap, percentage overlap;

seam gap, seam thickness and body hook butting% are measured.

The values can be stored in a Excel file and are displayed in on-screen if values are within specs.

Seam image can be printed, stored!

|

|

| Total page:1

Current page:1 Total records:28 |

First | Previous | Next | Last

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|