|

| |

Product Classification : Can Making----3-Piece Can/Spray Can

|

| Total page:3

Current page:1 Total records:81 |

First |

Previous |

Next |

Last

|

|

|

CanNeed-DER-4 Digital Enamel Rater

|

|

The CanNeed-DER-4Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

CanNeed-DER-4 is the industry standard. The new CanNeed-DER-4Enamel Rater instrument test the coverage of the enamel coating inside food and beverage cans, aerosol-cans and also different kinds of ends. It displays an index of the amount of metal exposed by incomplete enamel coverage on a clear, easily read digital LED.

|

|

|

CanNeed-OCTG-2000 Coating Thickness Gauge

|

|

CanNeed-OCTG-2000 Coating Thickness Gauge is used to measure the coating thickness in real time, save time and improve the quality of the product. Non-contact optical measurement technology is applied to product development, laboratory quality control and online production control. In the solar energy industry, optical coating industry, food packaging,as well metal packaging, are very good choice to improve the surface quality of products: appearance, adhesion, corrosion resistance, abrasion resistance, scratch resistance.

|

|

|

CanNeed-CC-1000 Can Colorimeter

|

1. Special and professional design for samples in column shape. No need to cut cans. Easy to operate and sample-saving.

2. Spectrum gauge with linear array CCD analyzes the spectrum with resolution of up to 1nm.

3. High-speed test. Single test needs less than 50ms and one sample needs less than 1s.

4. Light source consists of several LEDs. Energy is even in the whole spectrum. Long Lifetime and stable.

5. Result is stable. Repeatability up to 0.05 △E.

6. Light source is conducted and spectrum is reflected by optical fiber, which makes the gauge accurate and compact.

|

|

|

CanNeed-DST-100 Seal Tester for Steel Drum

|

|

CanNeed-DST-100 Seal Tester for Steel Drum is developed to use compressed air in the steel drum (for example paint drum) to test the inner pressure resistance. It has the advantages of simple structure, convenient use, is the steel drum manufacturers/users, as well as inspection institutions’ preferred testing equipment.

|

|

|

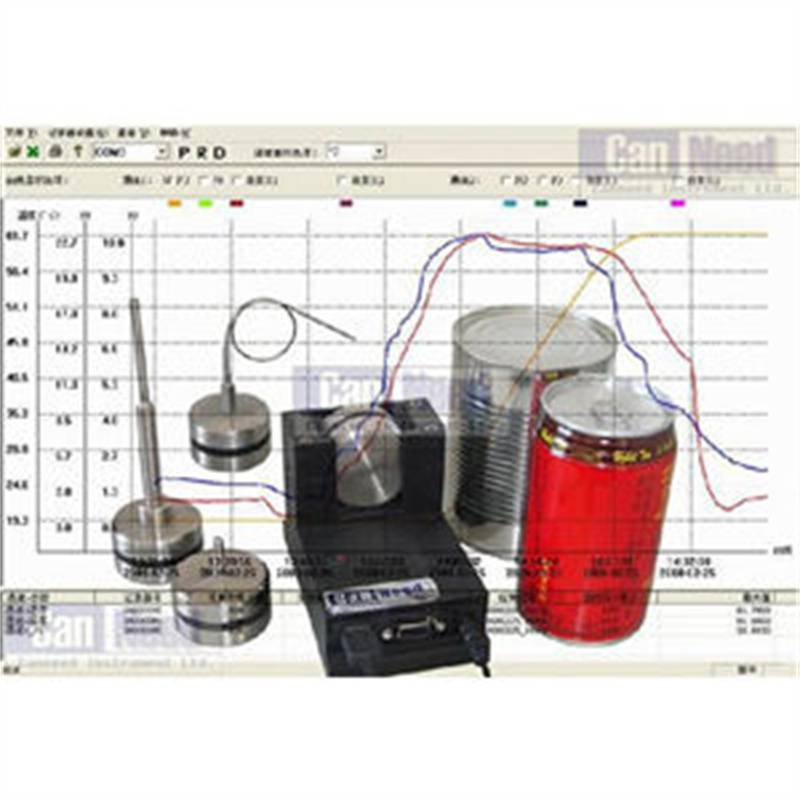

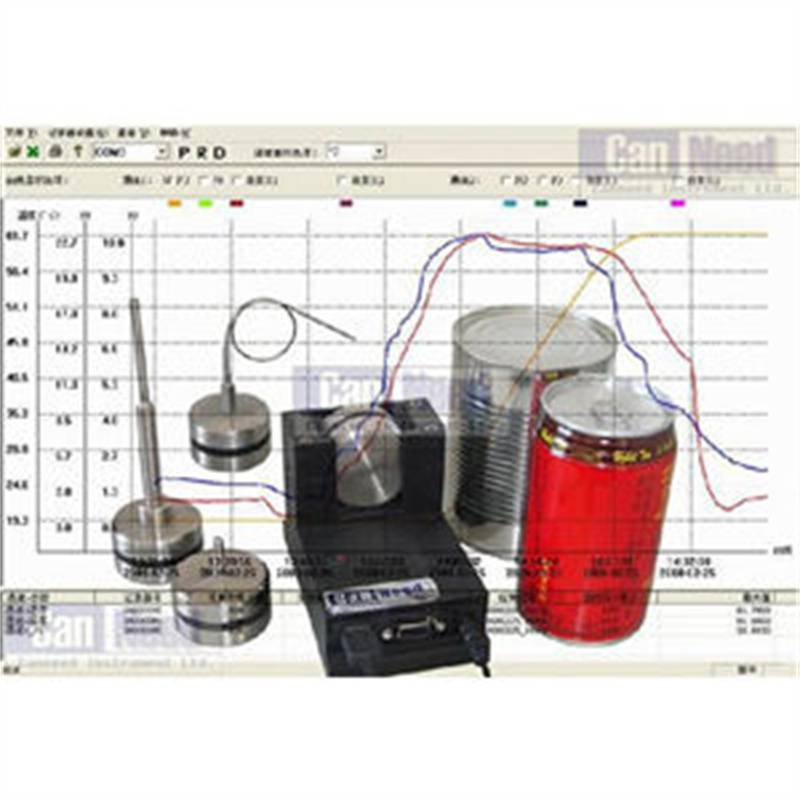

CanNeed-F-125 Sterilization Temperature Monitor (F0 Value Monitor)

|

|

CanNeed-CAN-F-125 Sterilization Temperature Monitor (F0 Value Monitor) has been chosen by many

beverage and canned food factories.

Applicable to different kinds of sterilization equipments and different place that require temperature monitoring: sterilization kettle (autoclave), Spray sterilization machine, Water sink sterilization machine, warehouse, transportation vehicles, etc.

Applicable to different kinds of products: canned food, beverage, beer, pouch food, jelly, etc.

Applicable to different kinds of packaging: metal cans, glass or PET bottles, pouches, plastic boxes, etc.

|

|

|

CanNeed-FSF-100 Tinplate Holder

|

|

The CanNeed FSF-100 Tinplate Holder is used together with the CanNeed-DER-400 Digital Enamel Rater and the vacuum device to test the integrality of the enamel coating inside the tinplate.

|

|

|

CanNeed-ACH-100 Aerosol Curl Height Gauge

|

|

CaNneed-ACH-100 Aerosol Curl Height Gauge is used for measuring the contact height of the curl 1” aperture of aerosol cans. ACH-100 is the Industry Standard.

|

|

|

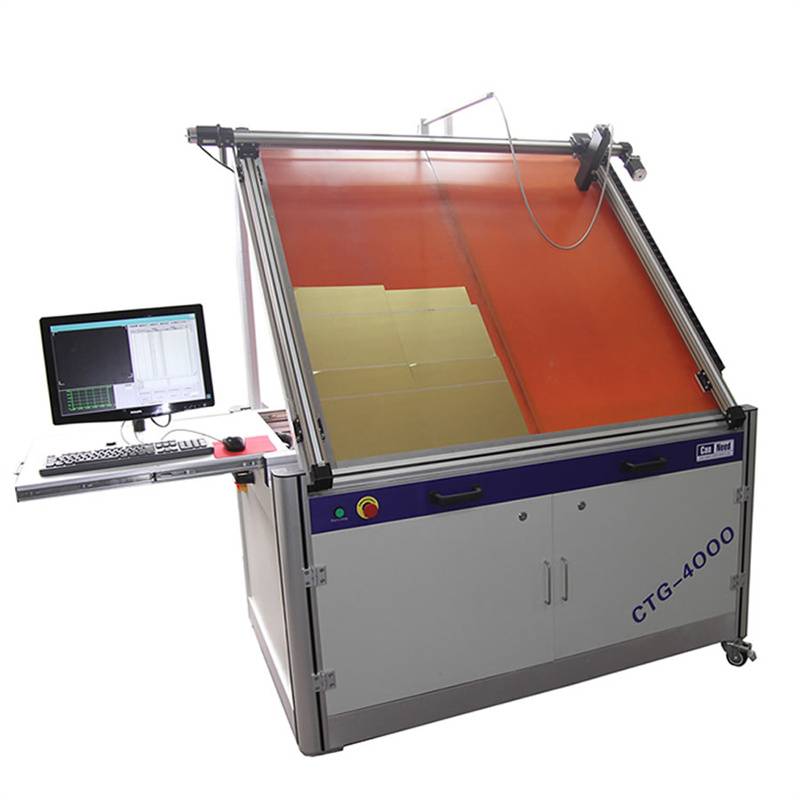

CanNeed-OCTG-4000 Thickness Gauge and Wet Film Thickness

|

Measure real-time thickness of coating and welt film.Save time and improve quality

Deliver real-time results on single or dual layers

Adopt non-contact optical technology,applicable for R&D,QC,and on-line production

In solar energy,optical filming,food packaging and metal packaging industries, improve surface quality such as appearance, adhesion, corrosion resistance, wear resistance, and scratch resistance.

|

|

|

Seam-X-On-line X-Ray Automatic Seam Scanner(Non-destructive)

|

|

The CanNeed “Seam-X-On-Line X-Ray Automatic Seam Scanner” adopts non-destructive measurement method to measure the seam quality, suitable for measuring the aluminum cans, steel cans , aluminum-iron composite cans and etc. It’s applicable for online in producing department. It’s a non-destructive, cost saving, accurate measurement and automatic equipment which can be installed on the production line to improve the sampling frequency.

Advantages:

01)Non-destructive measurement, avoid wasting samples

02)Non-destructive measurement, avoid environmental pollution and save handling charges

03)High sampling frequency, reduce the isolation inferior

04)High sampling frequency, cost saving

05)Can track the chucks corresponding to the unqualified products

06)360-degree fully scan measurement

07)Can be suitable for various types of cans

08)Higher accuracy

09)Avoid manual measurement error

10)Durable

11)Accord with the worldwide safety standards

|

|

|

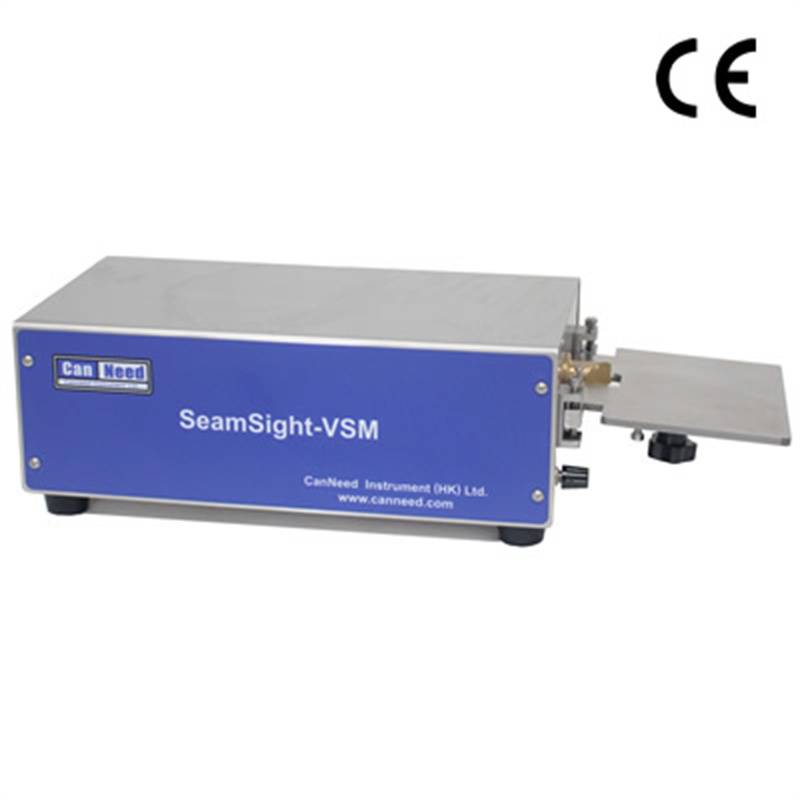

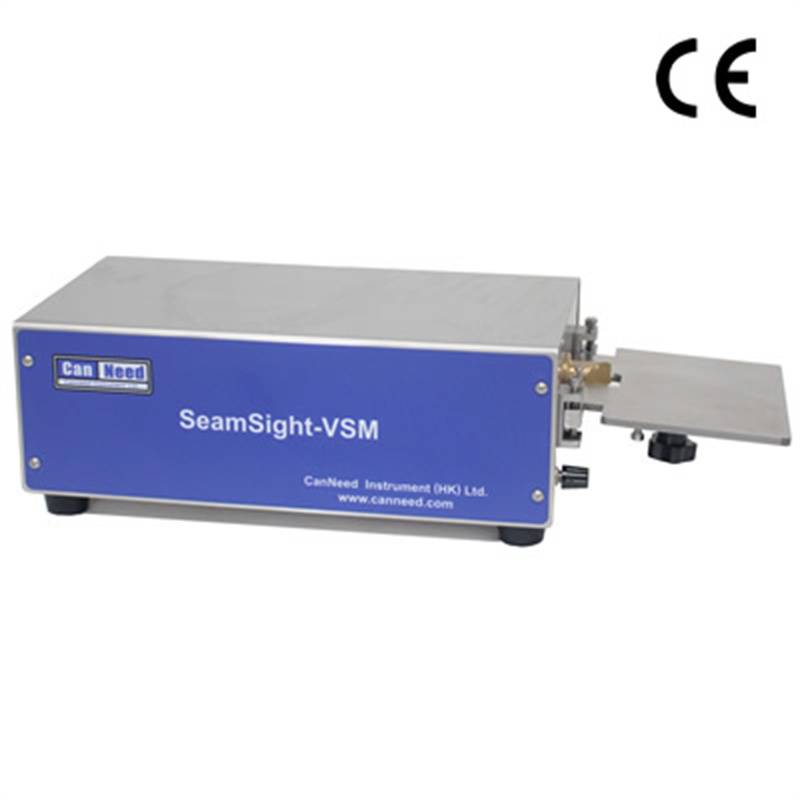

SeamSight®-VSM-6D Automatic Seam Monitor

|

SeamSight-VSM-6D Automatic Seam Monitor uses the CanNeed SPC data collection system, The actual seam thickness, actual countersink, etc., can be transferred to the computer automatically.

The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

|

|

|

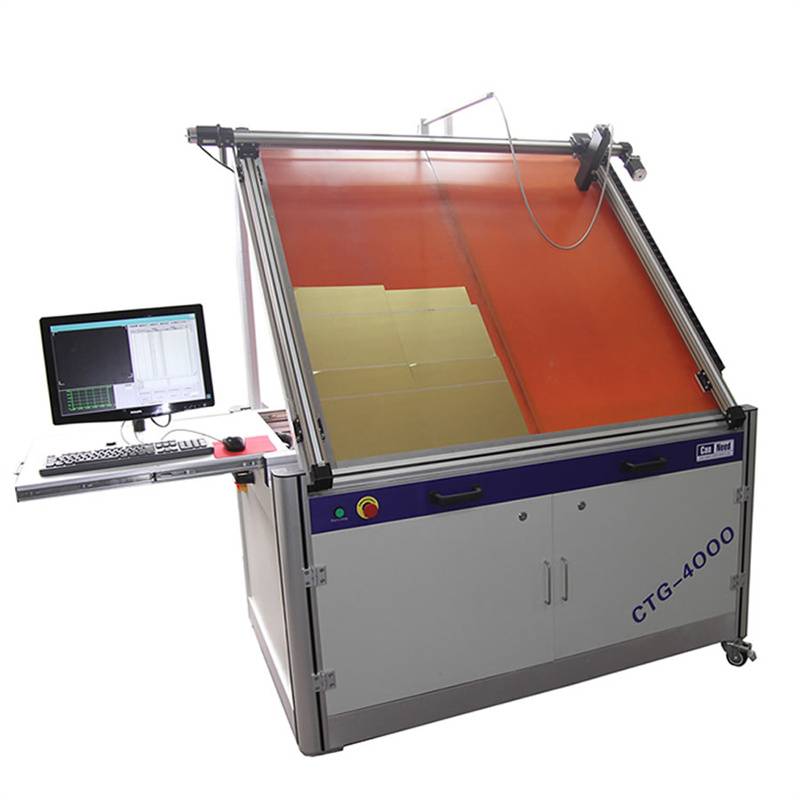

CanNeed-ZM-1800-D Digital Body Blank Gauge

|

|

CanNeed-ZM-1800-D Digital Body Blank Gauge is made to measure the length, width and perpendicularity (angle) and the diagonal on the blank Sheets.

|

|

|

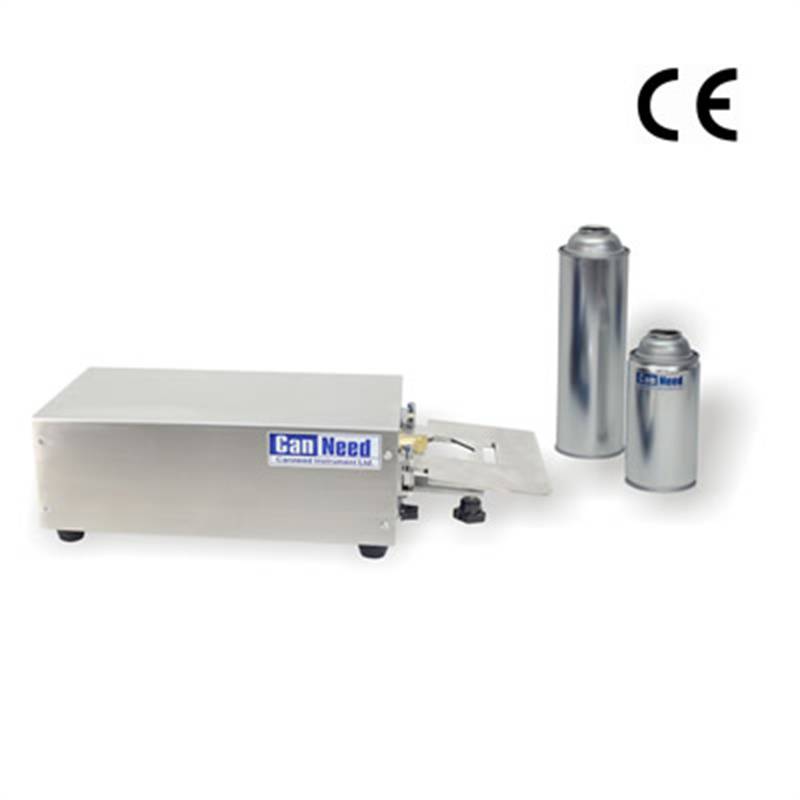

CanNeed-ALT-800 Leak Tester for Aerosol can

|

|

Canneed-ALT-600/ALT-800 Leak Tester for Aerosol can is used for testing the leakage of Aerosol cans. ALT-600 can test 6 cans at the same time, and ALT-800 can test 8. The permeability tester for aerosol cans blows up the cans up to a maximum of 10 bar and submerges them under water. At the leaking spots of the can then visible air-bubbles escape.

|

|

|

CanNeed-ALT-100 Leak Tester for Aerosol can

|

|

CanNeed-ALT-100 Leak Tester for Aerosol can is used for testing the leakage of Aerosol cans in a water bath. The can is freely suspended and submerged into the water. At the same time it is subjected to pressure and leaks are revealed by air bubbles. Test pressure 8 - 10 bar. The test procedure is performed semi-automatically. The tester is suitable for all aerosol can diameters. The maximum can height is 300 mm.

|

|

|

CanNeed-AFMD-200 Aerosol Can Measure Desk For Front End

|

|

AFMD-200 Aerosol Can Measure Desk for Back End is used in aerosol can product line. Measures bottom &wall thickness, can body diameter, can height. Pls state can type when place an order

|

|

|

CanNeed-ACMD-200 Aerosol Can Measure Desk For Back End

|

CanNeed ACMD-200 Aerosol Can Measure Desk for Back End is used to the production line of aerosol cans.

Measures bottom & wall thickness, bottom depth, can height, external & internal diameter.

Please specify the can types when ordering.

|

|

|

CanNeed-ABT-200 Burst Buckling Tester for aerosol cans

|

Aerosol can manufacturers need not only to save cost but also to ensure product quality, they are in a great need about devices which can accurately measure and assess the performance of the aerosol cans.

CanNeed-ABT-200 Burst Buckling Tester for Aerosol Cans is used for testing the buckle value of bottom and end (dome) of aerosol cans and the pressure at which the can bursts.

|

|

|

CanNeed-ABT-100 Burst Buckling Tester for Aerosol Cans

|

|

CanNeed-ABT-100 Burst Buckling Tester for Aerosol Cans is used to determine the buckle value of bottom (dome) and Top end of aerosol cans and the pressure at which the can bursts. With the special designed clamp, it is able to measure the dome or bottom free ends independently. At high pressures from approximately 22 - 28 bars, it may happen that deformations of the valve and a higher burst pressure.

|

|

|

CanNeed-CST-100 Can Seal Tester (Vacuum mode)

|

|

CanNeed-CST-100 Can Seal Tester (Vacuum mode) is for testing the secure seal of the 3-pc cans by applying the vacuum pressure to see whether the cans leak. It can test 1 (one) round can at each test.

Test method: Fill the sample can with water, cover the transparent platen on the open top, turn on the vacuum pump to generate the negative pressure, and then observe whether there are air bubbles on the can body, if the air bubbles come out continually, that means leakage occurred.

CanNeed-CST-100 is applicable for different can sizes. Please order different platens accordingly.

|

|

|

CanNeed-DHG-500 Digital Can Height Gauge

|

|

The CanNeed-DHG-500 Digital Can Height Gauge can be used to measure the height of beverage, food, and aerosol cans. The gauges can be connected to a computer or SPC system via the adapter and cable.

|

|

|

Seam-X-On-Line-T Full Automatic Seam Scanner (Non-destructive & Automatic sampling)

|

Seam-X®-On-Line Automatic Seam Scanner adopts non-destructive measure method to measure the seam dimension. It is applicable to be installed by pass the production line, taking the samples and measuring them.

Measure Items: Seam Length, Body Hook, End Hook, Overlap, %Overlap, Seam Gap, %Body Hook Butting, and %End Hook Butting.

It’s applicable to measure cans of various materials. Combination of can body and the end can be following: (1) Aluminum & Aluminum; (2) Tin & Tin.

Seam-X®-On-Line can work together with the seam thickness gauge and countersink gauge, to make up a complete measure system for the double seam.

If configured with identification sampling system, it can make the result of every can correspond to the related seamer head.

|

|

|

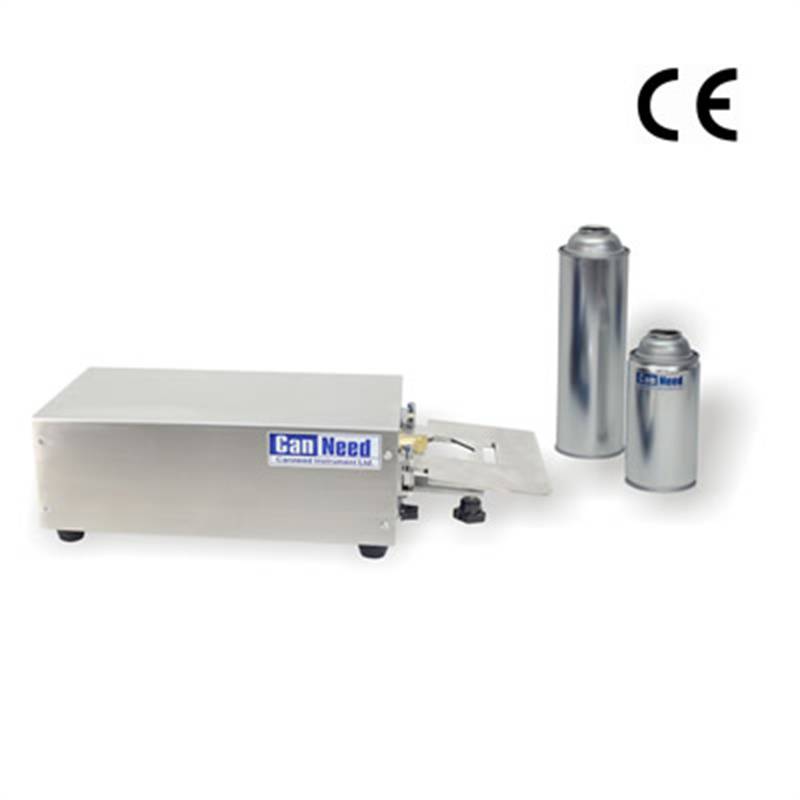

CanNeed-CSS-2000A Seam Saw for Aerosol Cans

|

|

The CanNeed-CSS-2000A Seam Saw is a special seam circular saw with double cut for double seam inspections. The CanNeed-CSS-2000A was specially designed for aerosol cans.The nitrated blades achieve together with the speed of approx. 1.000 r/min. a very plain cut surface. The seam image on Caneed series Automatic Seam Computer (Video Seam Monitors), and automatic seam measuring systems gets thereby very clear and improves measurement speed and reliability.

|

|

|

SeamSight®-VSM-6C Automatic Seam Monitor

|

SeamSight-VSM-6C Automatic Seam Monitor is a compact measuring system for quick and accurate automatically seam measurements, it has adopted the advanced optical system and Golden LensTM video capture device, which ensured the high image definition and the measurement accuracy.

SeamSight-VSM-6C Automatic Seam Monitor is equipped with the professional seam measuring software CanNeed-CND_VSM3.0. With the CanNeed SPC data collection system, the data of actual seam thickness, actual countersink, etc., can be transferred to the computer automatically.

|

|

|

SeamSight®-VSM-6A Automatic Seam Monitor

|

|

SeamSight-VSM-6A Automatic Seam Monitor is a compact measuring system for quick and accurate automatically seam measurements, it has adopted the advanced optical system and Golden LensTM video capture device, which ensured the high image definition and the measurement accuracy.

SeamSight-VSM-6A Automatic Seam Monitor is equipped with the professional seam measuring software CanNeed CND_VSM3.0. With the CanNeed SPC data collection system, the data of actual seam thickness, actual countersink, etc., can be transferred to the computer automatically.

|

|

|

SeamSight®-D Full Automatic Seam Monitor

|

|

The SeamSight® system is equipped with the new seam measuring software SeamSight® Professional Software. Which will do the line positioning automatically and the measurement to be finished within 1 second!

Use the CanNeed SPC data collection system, The actual seam thickness, actual countersink, etc., can be transferred to the computer automatically.

The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

|

|

|

SeamSight-A Full Automatic Seam Monitor

|

|

The SeamSight® system is equipped with the new seam measuring software SeamSight® Professional Software. Which will do the line positioning automatically and the measurement to be finished within 1 second!

Use the CanNeed SPC data collection system, The actual seam thickness, actual countersink, etc., can be transferred to the computer automatically.

The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

With CanNeed Automatic Seam Sight® Monitor, press only one key “Auto Measure” to do the line positioning automatically and the measurement to be finished within 1 second! It can measure the seam dimension automatically, efficiently, simply and also avoid operator mistake. Use the CanNeed SPC data collection system (CSG-200 countersink gauge & STG-200D seam thickness gauge), the actual seam thickness, actual countersink, etc., can be transferred to the computer automatically. Such data can generate a report together with other data, improving the process.

|

|

|

CanNeed-SCG-110 Seamer clearance Gauge and Seam Monitor

|

|

CanNeed-SCG-110 Clearance gauge, is a quick and accurate way to set up seamers. To measure the roll height off the chuck and the lateral distance between the roll and chuck.

The Clearance Gauge takes a completely different approach to the problem. To measure the roll height off the chuck and the lateral distance between the roll and chuck.

The Clearance Gauge allows users to do predictive maintenance on their seamers before they go out of specifications. The clearance gauge is able to not only quickly and accurately set up the seamer, but makes sure that all the seamer heads are performing perfectly as near as possible to the nominal value.

Instead of focusing on checking seams after the double seam is already closed, the Clearance Gauge helps optimize the can seaming process by taking out variations between the different seamer heads and optimizing the seamer itself!

Today, covering most seamer models, these seamers show a clear and dramatic performance improvements by using this gauge.

|

|

|

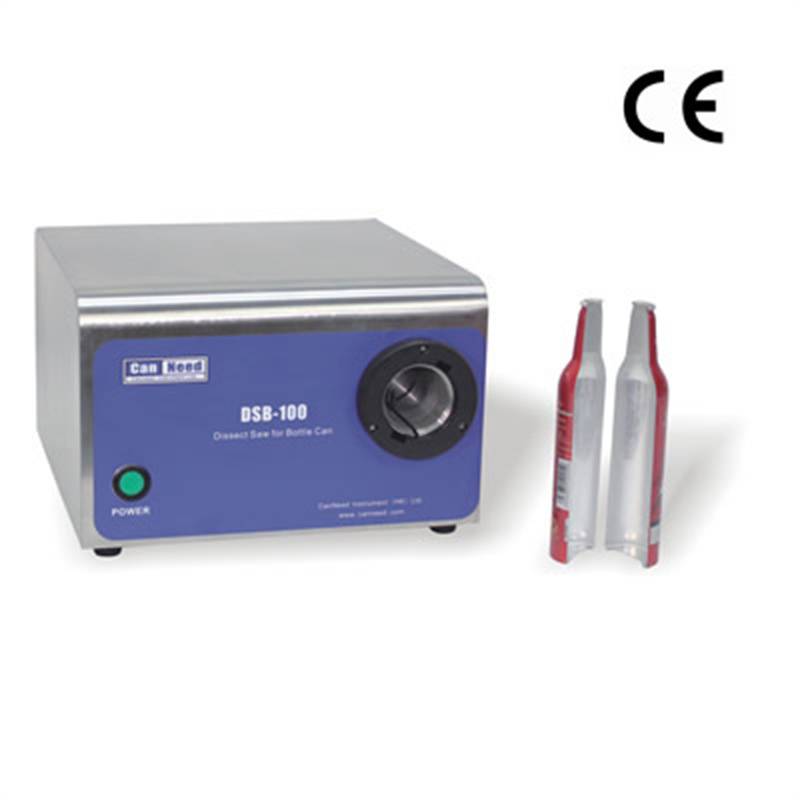

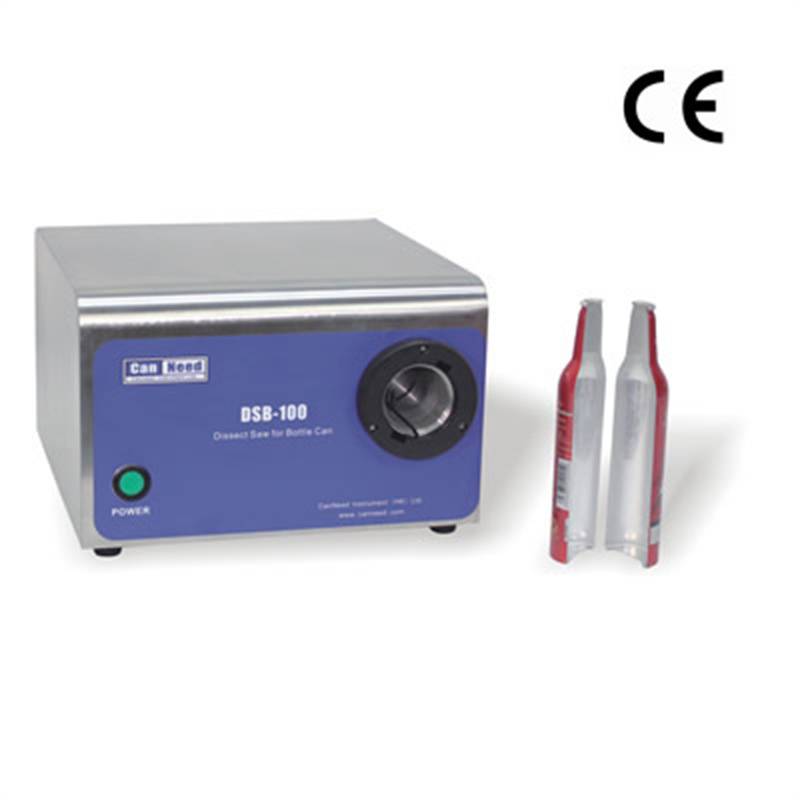

CanNeed-DSB-100 Dissect Saw for Bottle Can

|

|

CanNeed-DSB-100 Dissect Saw for Bottle Can cuts the cans into two half for can inspections. We can observe the corrosion or coating problem inside the can. DSB-100 is provided with a safe design toavoid cutting the finger. The blade is very hard and durable.

|

|

|

CanNeed-CMT-300 Mobility/Lubricity Tester for Cans (Digital)

|

|

CanNeed-CMT-300 Mobility / Lubricity Tester for Cans is for measuring the coefficient of sliding friction of can body and bottom. It can also measure the coefficient of sliding friction of blanks.

Install the corresponding clamp and place the sample on the clamp, then put the bob-weight unit on the sample. Pull the bob-weight and the indicator will display the coefficient of sliding friction.

|

|

|

CanNeed-CMS-1000 Automatic Measure System for Food Cans

|

|

CanNeed-CMS-1000 Automatic Measure System for Food Cans is used to measure Flange Width, Can Height ,the bead depth of the can body and the bead space distance of the can body of 3-pc can.

|

|

|

CanNeed-CLT-300 Leak Tester for can

|

|

The “CanNeed-CLT-600 Leak Tester for can “ is used for checking the leakage of 3-piece cans in a water bath. It can test six cans in each test.

Testing method: Place the sample cans to the platen, the cans will be fixed by the magnet disc plate, clamp the cans to seal the top, then submerge the cans into water and apply pressure to the cans.

Observer the can body to see whether there are bubbles come out, if bubbles come out from the can body constantly, that means the sample cans leak.

During the testing, operator is able to turn the samples over for easy observing the can top, can bottom, can body and welding line.

The test procedure is performed semi-automatically and the tester is suitable for different sizes of round 3-piece cans.

|

|

| Total page:3

Current page:1 Total records:81 |

First |

Previous |

Next |

Last

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|