|

| |

Product Classification : Can Making----2-Piece Can/Aluminum Bottle

|

|

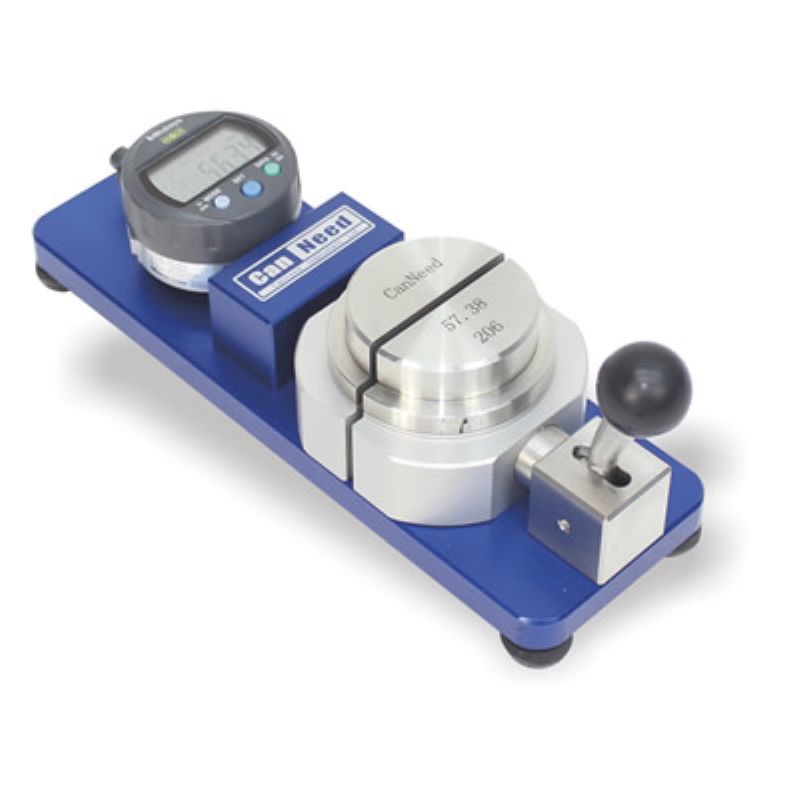

CanNeed-FMD-200S Can Measure Desk for Front Stations

|

|

CanNeed-FMD-200S Can Measure Desk for Front Stations is developed on basis of the long experience of Front Stations in

2 -piece can product line. It is applied at the inspection points of 2 -piece can product line.

CanNeed-FMD-200S measures the Wall Thickness, Bottom Depth, Can Height. Please indicate the can type when ordering.

|

|

|

SeamSight®-VSM-6B Automatic Seam Monitor

|

SeamSight-VSM-6B Automatic Seam Monitor is a compact measuring system for quick and accurate automatically seam measurements, it has adopted the advanced optical system and Golden LensTM video capture device, which ensured the high image definition and the measurement accuracy.

SeamSight-VSM-6B Automatic Seam Monitor is equipped with the professional seam measuring software CanNeed-CND_VSM3.0. With the CanNeed SPC data collection system, the data of actual seam thickness, actual countersink, etc., can be transferred to the computer automatically.

|

|

|

CanNeed-ACBT-1000 Automatic Buckle Tester Bottom for Can

|

CanNeed-ACBT-1000 Automatic Buckle Tester is a full automatic buckle tester bottom for cans with unattended operation.It determines the exact pressure at which the can bottom begins to buckle respectively the dome reverses with dome growth function. CanNeed-ACBT-1000 is a standard instrument for can-making industry which can respectively and efficiently finish auto online measurement.

CanNeed-ACBT-1000 is equipped with auto sampling device which conveys the can to the testing area automatically. Swinging mechanical hand pushes the can to the testing station and it will measure automatically. There is no need to change the clamps, applicable for empty necked-in cans and straight wall cans at the same time. There is no need to change the clamps, applicable to test the cans with different diameters and different heights at the same time. Testing results can be saved in database and automatically transferred to SPC system.

|

|

|

CanNeed-AAXL-2000 Automatic Axial Load Tester

|

CanNeed-AAXL-2000 is a full automatic can axial load measure system with unattended operation. It can measure the axial load of the 2-piece can. It is a standard instrument for can-making industry which can realize the constant, efficient and automatic inspection for cans.

CanNeed-AAXL-2000 is equipped with auto sampling device which conveys the can to the test area automatically. Intelligent mechanical arm puts the can on the test station and the top tray falls to reach the sample. When the force exceeds the can load limit, can deforms. Test curve will be showed on the screen. Mechanical arm will take the sample out after test. It is suitable for cans with different diameters of can mouth. Test result is saved in database and is sent to SPC system automatically.

|

|

|

CanNeed-CBT-CAL Calibration Cell For Buckle Tester

|

|

According to ISO and measuring management,users need to calibrate equipments at fixed period,but it is not convinient to send equipments to measuring organizations for calibration,then this CanNeed-CBT-CAL will help.

CanNeed-CBT-CAL is used to calibrate CanNeed-CBT-100/200/300, CanNeed-CBBT-100,CanNeed-CEBT-100, CanNeed-EBT-200/300

CanNeed-CBT-CAL display real time pressure,compare the value that displaying on CanNeed-CBT-100/200/300, CanNeed-CBBT-100, CanNeed-CEBT-100, CanNeed-EBT-200/300 to make the calibration.

|

|

|

CanNeed-AFMS-2000 Automatic Can Measure Desk for Front Stations

|

CanNeed-AFMS-2000 is a full automatic front end measure system with unattended operation. It can measure the wall thickness of upper and middle parts of the can, bottom depth and height of the can. It is a standard instrument for can-making industry which can realize the constant, efficient and automatic inspection for cans.

AFMS-2000 is equipped with auto sampling device which conveys the cans to the test area automatically. Swinging mechanical hand pushes the can to the test station then three-jaw centering mechanism locates the can quickly. Swinging device rotates the can to a defined angle to get various testing point. Test result is saved in database and is sent to SPC system automatically.

|

|

|

CMT-200 Mobility/ Lubricity Tester for Cans

|

|

The CanNeed “CMT-200 Mobility / Lubricity Tester for Cans” is for measuring the coefficient of sliding friction of can body and bottom. It can also measure the coefficient of sliding friction of blanks.

Install the corresponding clamp and place the sample on the clamp, then put the bob-weight unit on the sample. Pull the bob-weight and the indicator will display the coefficient of sliding friction.

|

|

|

CTG-300 Coating Thickness Gauge

|

|

The Canneed's "CTG-300 Coating Thickness Gauge", equipped with aerodynamic levitation measuring head, provides a computer enhanced method of rapidly assessing lacquer film weight of both internal and external coatings on beverage and food cans, and also tinplate.

The system provides the following benefits to the Can and End manufacturer:Reduced lacquer consumption, Greater product quality, Better operating efficiencies and Lower spoilage.

|

|

|

CTG-4000 Wet Film and Coating Thickness

|

Application:

1. Test wet film and coating thickness,both save time and improve quality

2. Test both single layer and multilayer coating

3. Adopt non-contact optical technique,suitable for research,quality control and on-line control.

4. Can be used in Solar energe,optical coating,foods package,metal package field.Improve the quality by appearance,adhesion,resistant to corrosion and fricton,as well as scratch.

|

|

|

CanNeed-DER-400 Digital Enamel Rater

|

|

CanNeed-DER-400 Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

CanNeed-DER-400 is the industry standard. The new CanNeed Enamel Rater DER-400 instrument test the coverage of the enamel coating inside food and beverage cans, aerosol-cans and also different kinds of ends. It displays an index of the amount of metal exposed by incomplete enamel coverage on a clear, easily read digital LED.

|

|

|

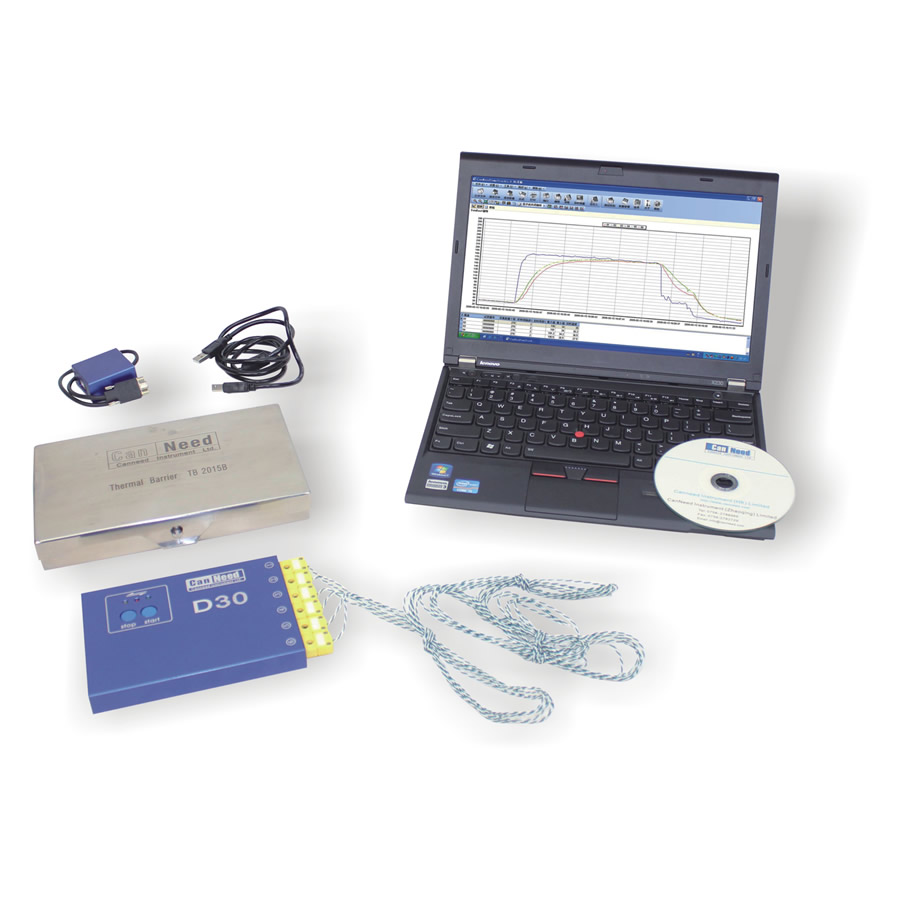

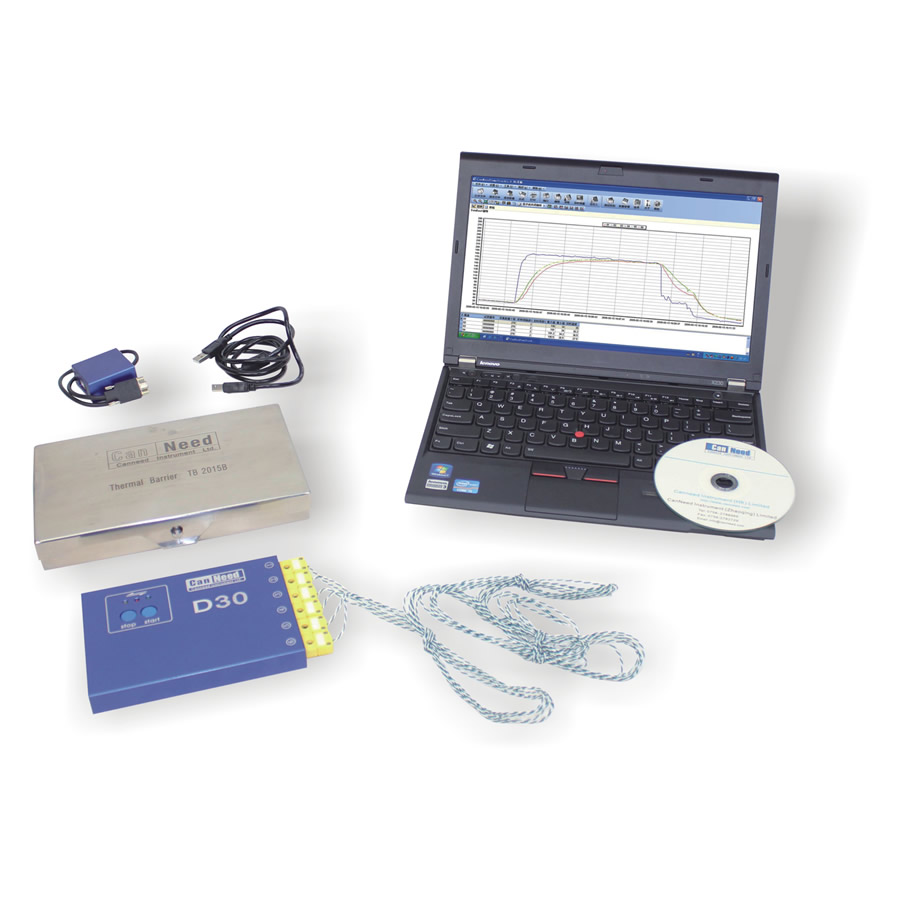

CanNeed-CND-TRK-300 Oven Temperature Tracker

|

|

The “CanNeed-TRK-300 Oven Temperature Tracker” is a professional oven temperature curve inspection system for the coating industry, it is including the data logger, heat insulation case, software (Chinese / English) and thermocouples.

"CanNeed-TRK-300 Oven Temperature Tracker” is use to pass through the oven with the solidifying products, and record down the real temperature during the process. The logger is in the centre of the system. Heat insulation case is for protecting the logger from over heat by the oven. When passing through the oven, the CanNeed-TRK-300 Oven Temperature Tracker will record down the real time temperature of the solidifying products through the 5 thermocouples which were connected to the products, and one thermocouple is for recording the air temperature of the oven. After the recording process was finished, use the CND_TRK Software to analyze the temperature data and generate the detail reports.

|

|

|

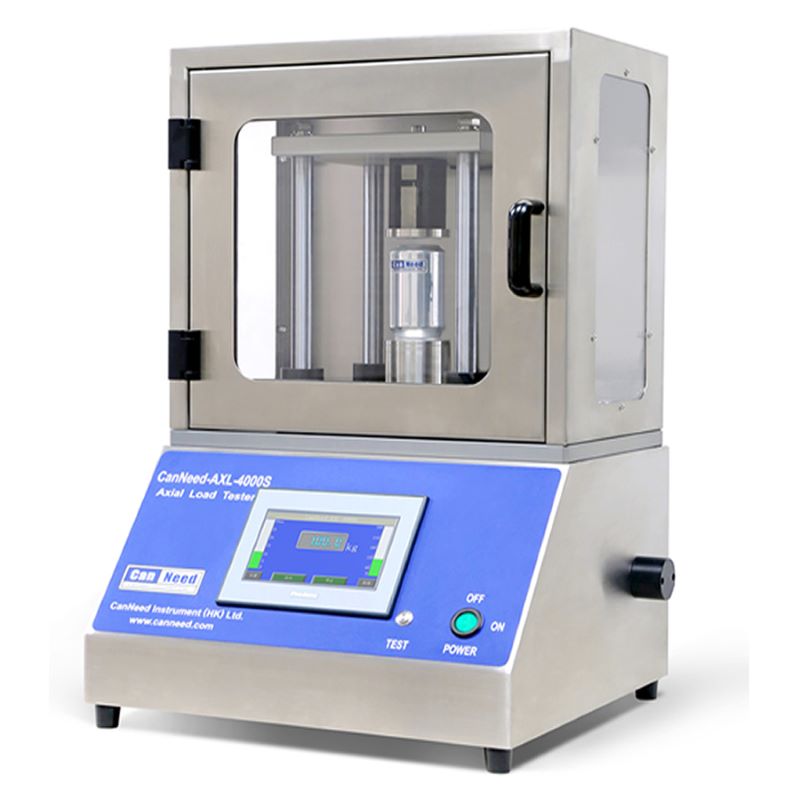

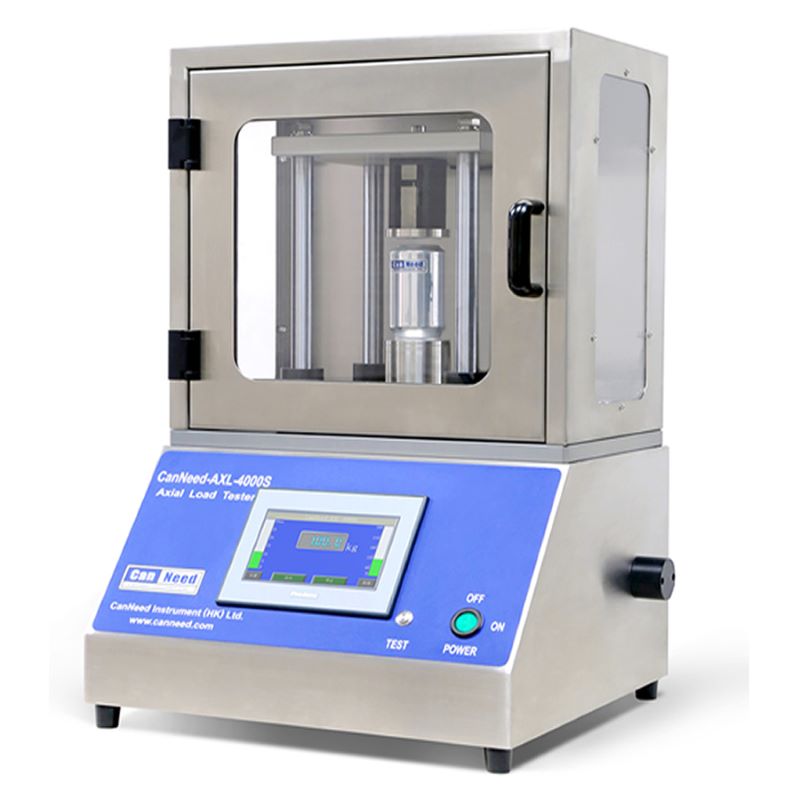

AXL-4000 Axial Load Tester

|

|

The "CanNeed AXL-4000 Axial Load Tester" measures the axial force resistance of beverage cans in Newton. The can is placed in a support and gradually forced upwards against the pressure plate. The space between the support and the top plate can be altered with spacers. The can crashes after the peak force has been applied that the can is capable of resisting. The maximum value can now be read in the display.

|

|

|

AXL-CAL Calibration Cell for Axial Load Tester

|

|

The CanNeed AXL-CAL use to calibrate the AXL-4000 Axial Load Tester. Place the AXL-CAL into the testing platform and rise up gradually until reaches the top plate, then the AXL-CAL will display the real time pressure, compare the value that displaying on the AXL-4000 to make the calibration.

|

|

|

Seam Sight 3B Portable Full Automatic Seam Monitor

|

|

The CanNeed "Seam Sight 3B Portable Full Automatic Seam Monitor" is so small and portable to work with a laptop. It was packed with the CSS-P2 into a suitcase, specially designed for those who always on business trip.

The "Seam Sight 3B Portable Full Automatic Seam Monitor" has adopted the advanced optical system and Golden LensTM video capture device, which interference-free of external light source and ensured the high image definition and the measurement accuracy. The Seam SightTM system is equipped with the new seam measuring software - Seam SightTM.

|

|

|

CSS-P3 Portable Seam Saw

|

|

The CanNeed "CSS-P2 Portable Seam Saw" is a special seam circular saw with double cut for can double seam inspections. The CSS-P2 was specially designed for 2- and 3-piece cans. Also aerosol-cans may be sawed with this saw. The nitrated blades achieve a very plain cut surface. The seam image on "VSM Automatic Seam Monitor", and automatic seam measuring systems gets thereby very clear and improves measurement speed and reliability.

|

|

|

CBT-200 Buckle Tester Bottom for Can

|

|

The "Canneed CBT-200 Buckle Tester Bottom for Cans" determines the exact pressure at which the can bottom begins to buckle respectively the dome reverses.

The empty flanged can or straight wall can is placed in the holder. After covering the device with a plexiglass hood pressure is applied. The can is sealed with a rubber o-ring structure. Fast pressure increase up to 5 bar (programmable to just bellow the expected buckle value), from there the "speed of pressure increase" may be set within the device. The test is terminated as soon as the can buckles. The maximum pressure value is shown in the display.

|

|

|

CEBT-100 Buckle Tester for Can and End

|

The "Canneed CEBT-100 Buckle Tester for Can and End" determines the exact pressure at which the Can and End begins to buckle. With 4 measuring mode:Buckle Bottom For Can (Including straight wall cans, necked-in cans),Peak Test For Free End, Missile Test for Free End and Peak Test for Seamed End.

1. Buckle Bottom For Can (Including straight wall cans, necked-in cans)

2. Peak Test For Free End

3. Missile Test for Free End

4. Peak Test for Seamed End

|

|

|

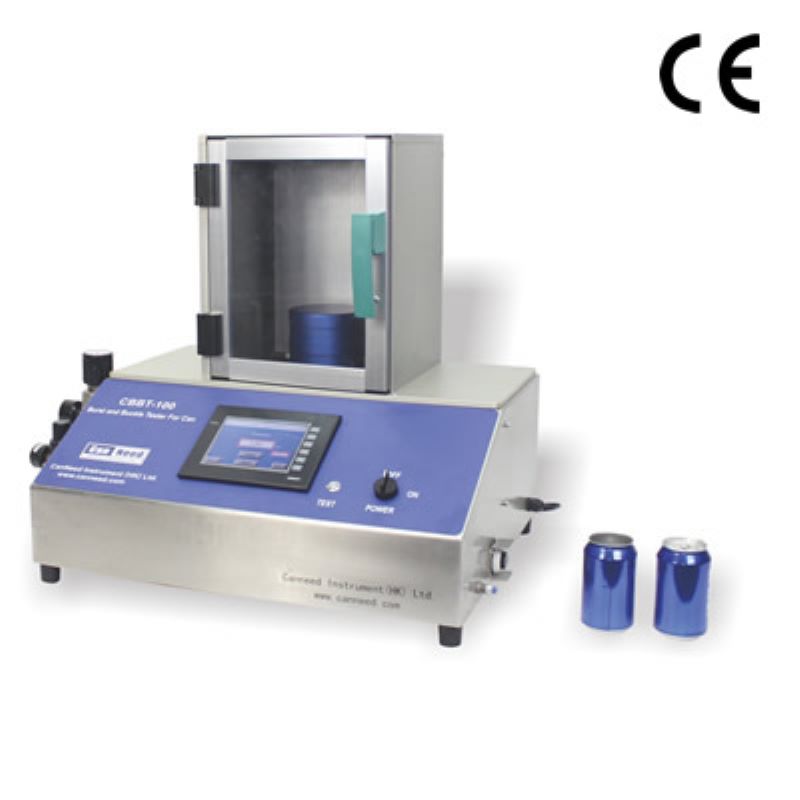

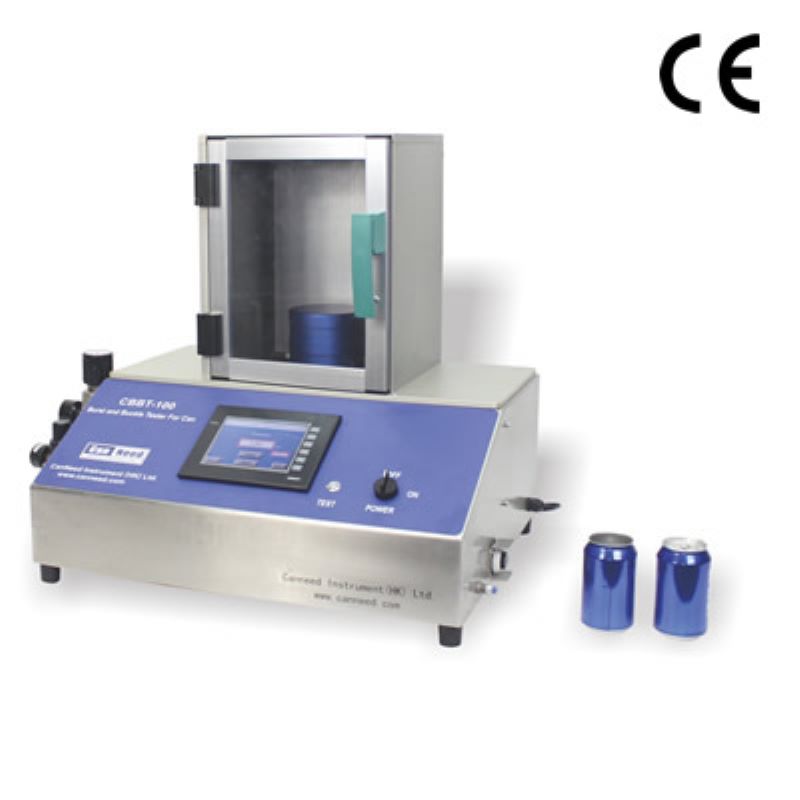

CBBT-100 Burst and Buckling Tester for Can

|

|

In order to control the cost and quality,it is necessary for 2 piece can manufacturers to buy an equipment which can accurately test the compression strength and burst strength.

The CanNeed CBBT-100 is used to test the pressures values of 2 piece cans:buckle value,burst value.Record the 2 values automatically.

It can test different diamter and height of cans with different clamps.

|

|

|

CanNeed-SM-24 Electric Belt Drive Seamer

|

|

The Canneed "SM- 24 Electric Belt Drive Seamer" (Desktop model) enables the users to do more lab tests. Such as, adjusting some technique, enhancing the products quality, test the empty cans and free ends, to insert a temperature logger into a can before running a temperature monitoring.

|

|

|

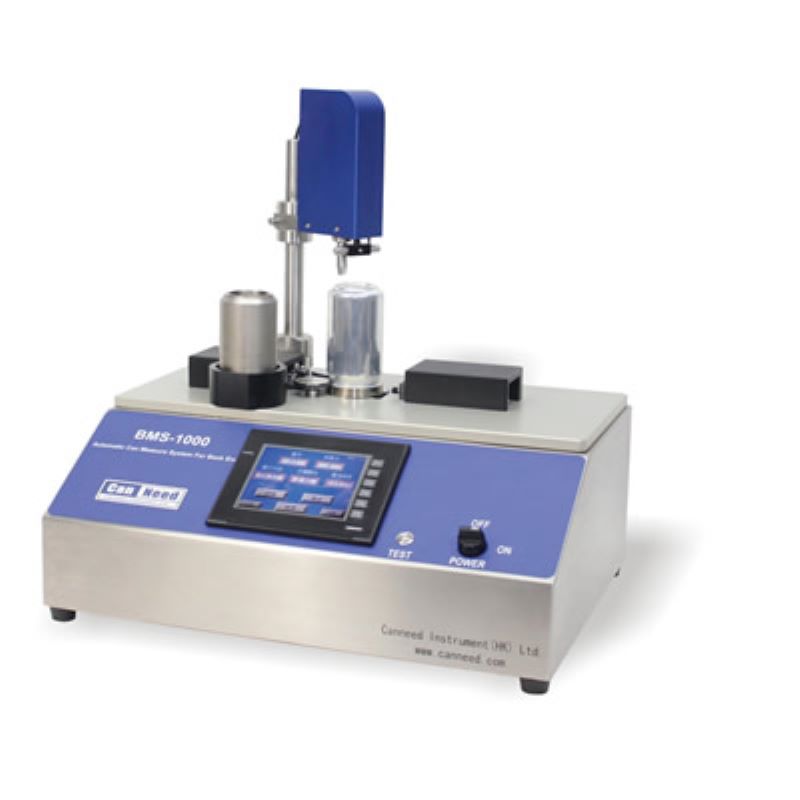

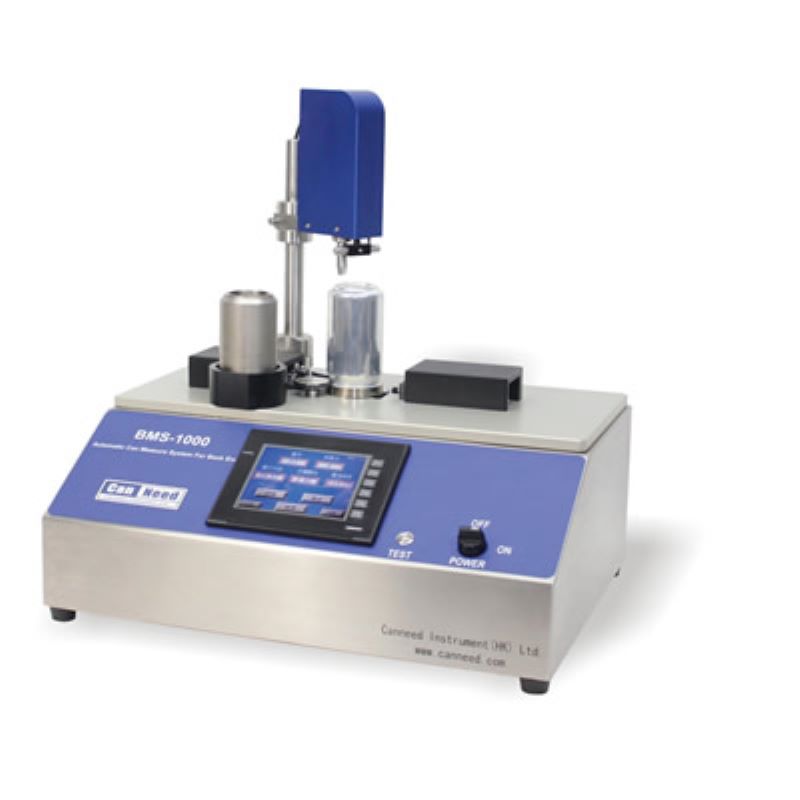

BMS-1000 Automatic Can Measure System for Back End

|

|

The CanNeed "BMS-1000 Automatic Can Measure System For Back End" is used to measure Flange Width, Can Height & Internal Diameter of 2-pc can. It’s designed by practical experience and applied to back end inspection. It can be adjusted rapidly and applicable for various can height.

|

|

|

CanNeed-WTG-200 Wall Thickness Gauge

|

|

The CanNeed-WTG-200 Wall Thickness Gauge measures the Top wall and Middle wall Thickness for Trimmed 2-Piece Cans. Available for any Trimmed 2-Piece Cans of any height (Please indicate the can height when ordering).

Configure with Mitutoyo Standard SPC Data Output and the resolution can reach 0.001mm.

If purchase the adapter and cable, the gauge can be connected to a computer or SPC system for data collection.

|

|

|

CanNeed-CMD-200S Can Measure Desk for Rear Stations

|

The CanNeed CMD-200 Can Measure Desk for Rear Stations is developed on basis of the long experience of Rear stations in 2 -piece can product line.

CMD-200 Measures the Flange width, can height, inner Diameter. Please indicate the can type when ordering.

|

|

|

BDG-100 Bottom Depth Gauge

|

|

The CanNeed "BDG-100 Bottom Depth Gauge" is a Digital gauges for measuring Bottom depth parameters of beverage cans. Please indicate the can diameter when ordering.

|

|

|

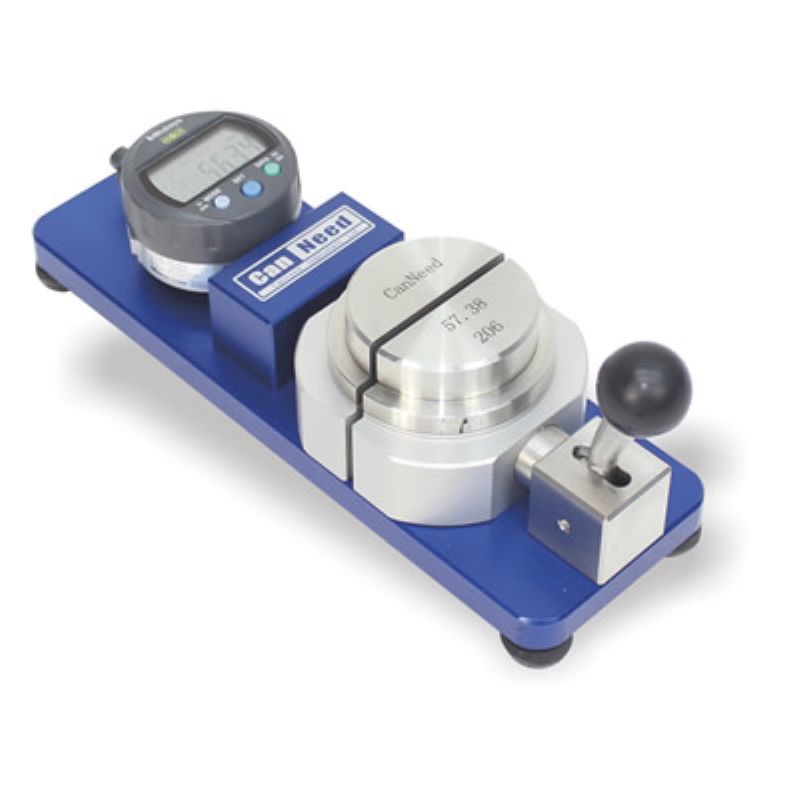

CanNeed-IDG-100/200/300 Can Internal Diameter Gauge

|

The “CanNeed-IDG-100 Internal Diameter of Can” is used to measure the internal diameter of small cans, such as 200, 202, 206, 209.

The “CanNeed-IDG-200 Internal Diameter of Can” is used to measure the internal diameter of larger cans. According to clients’ request, CanNeed-IDG-200 can be made to measure 2 to 3 different sizes of cans at the most at the same time. Note: The difference between the internal diameters of the two cans must be over 10mm.

When placing the order, please indicate the internal diameters of the cans, such as 202 neck-in cans, 206 neck-in cans.

With the Mitutoyo 0.01mm resolution digital indicator.

If purchased the adapter and cable, the gauge can be connected to a computer or SPC system for data collection.

|

|

|

CanNeed-DHG-300 Digital Can Height Gauge

|

|

The CanNeed "DHG-300 Digital Can Height Gauge" can be used to measure the height of beverage, food, and aerosol cans. The gauges can be connected to a computer or SPC system via the adapter and cable.

|

|

|

EPS-100 End Profile Systems

|

|

The CanNeed “EPS-100 End Profile System” is used to measure the end dimensions. It is with excellent

performance by adopting precise optics measuring technology, measuring the end dimensions precisely.The inaccuracy of end dimensions usually cause to such double seam defects as fault sealing, bearing

cover and false sealing and so on. It is hard to measure the profile dimensions of ends without EPS-100.

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|