|

| |

Product Classification : Canned Beer/Drinks

|

|

RDM-100 Radial Dimensions Measure Desk For Claw Twist Cap

|

|

RDM-100 Radial Dimensions Measure Desk For Claw Twist Cap is developed based on the long-term practical experience. It is applied to measure the radial dimensions of claw twist cap: cover outer diameter, cover inside diameter, claw diameter, claw width.

|

|

|

CanNeed-IAM-30 Air Meter

|

If the “CanNeed-IAM-30 Air Meter” is used together with CanNeed-CAN-7001 CO2 Tester and Pressure Tester, it can test CO2 content as well as the air content.

It is designed according to ASBC Theory of American Society of Brewing Chemists, corresponding to “GB/T 4928 – 2001 Brewing Analysis Methods” and “GB/T 10792 – 1995 Carbonated Beverage Analysis Methods”. Therefore, the machine is widely used by Quality and Technical Supervision Bureau and beverage enterprises.

|

|

|

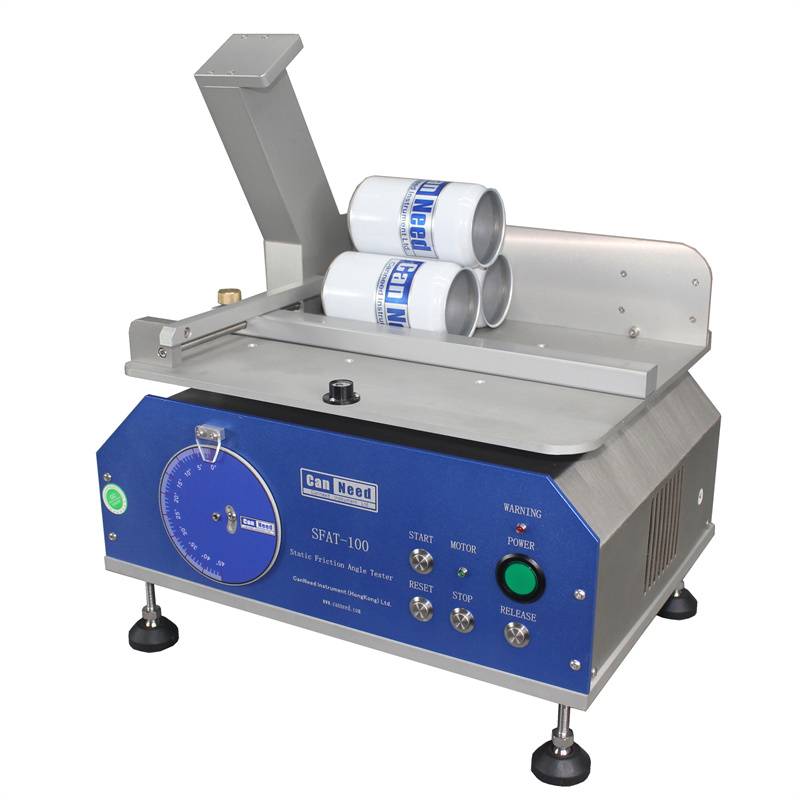

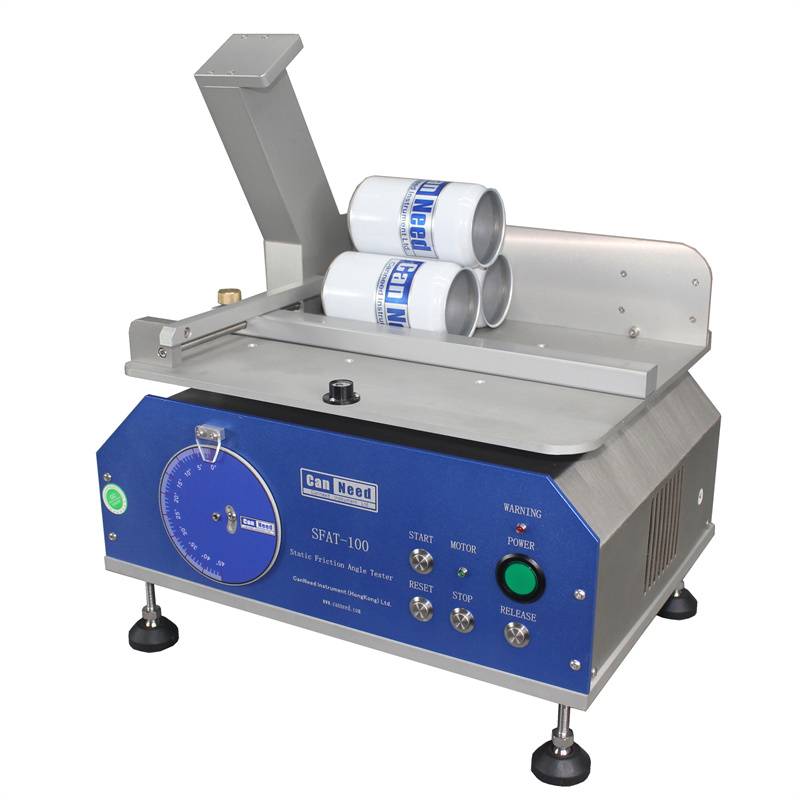

CanNeed-SFAT-100 Static Friction Angle Tester (Tilt Table)

|

|

CanNeed-SFAT-100 Static Friction Angle Tester enables accurate measurement of container lubricity and coefficient of static friction.

Three containers are placed on the table in a pyramidal configuration. After the start button is pushed, an electric motor increases the angle of inclination of the table. The bottom two containers are constrained and do not move during testing. When the tilt angle becomes great enough to overcome the frictional forces between the containers, the top container begins to slide and will contact the trip bar, which stops the drive motor and simultaneously applies a brake to the inclined table. This prevents coasting and inadvertent measurements of erroneously high tilt angles.

Applicable for: glass bottles, plastic bottles, aluminum bottles and cans, etc.

|

|

|

CND-SST-300 Secure Seal Tester(3 Stations)

|

|

The “CND-SST-300 Secure Seal Tester “is used to test seal integrity on the glass or plastic containers and cans. The CanNeed-SST-300 has been designed to address the special needs of sealing cans and bottles that use aluminum roll-on, twist crowns, or plastic caps. The CanNeed-SST-300 operates with compressed air, nitrogen, or carbon dioxide. By detecting gas leakage, rather than liquid, the Secure Seal Tester gives more sensitive, accurate readings.

|

|

|

CanNeed-CAN-1050D Digital Can Closing Force Gauge

|

|

CanNeed-CAN-1050D Can Closing Force Gauge is for measuring the force of seaming head of the seaming machine. By using CanNeed-CAN-1050d, producers can avoid product defects caused by over plating: sharp edge, seam breakage, body deformation, body hook overlength, over large countersink and so on. In the meantime, producers can also avoid product defects caused by too small pallet lift force: slippery cans, too short hook and so on.

|

|

|

CSS-1000 Anti-noise Seam Saw

|

|

CanNeed “CSS-1000 Anti-noise Seam Saw” is provided with an anti-noise design and a special guide

for 2-and 3-piece cans with 65mm dia, such as beer cans and 209 cans. The cutting process is so precise, quick, safe and convenient to ensure precise cutting effects without distorting the cans. The seam image on Canneed series Seam Sight TM automatic seam measuring systems gets thereby every clear and improves measurement speed and reliability.

|

|

|

BCC-7001W Digital Beverage CO2 Calculator

|

|

The “CanNeed-BCC-7001 Digital Beverage CO2 Calculator” is for measuring the CO2 content of the glass bottled, canned or PET bottled beer and other carbonated beverage. The operation is simple,when the measurement is carrying on, the CanNeed-BCC-7001 will calculate the CO2 automatically.

After the pierce head punctured into the container, shark the device together with the sample, start the device, then it will automatically calculate the temperature and pressure, and the result will be displayed on the screen.

The “CanNeed-BCC-7001 Digital Beverage CO2 Calculator” is applicable for different size of glass bottle,can and PET bottle.

If combine the IAM Air Meter for measuring, it would be able to measure the bottle neck air and total air content at the same time when measuring the CO2 content.

|

|

|

CanNeed-IPT-1000

|

|

|

|

|

ID-sampler-1000

|

|

|

|

|

CanNeed-PTM-100 PU Monitor Pasteurization Temperature Monitor

|

CanNeed-PTM-100 Pasteurization Temperature Monitor (PU Monitor) is used to test the temperature in the can/bottle in the pasteurization process. It can also test the temperature of the spraying water. It calculates the PU value and displays the temperature graph on the computer through CanNeed software or print report through printer.

Suitable for: canned beverage, beer products, can, glass bottle containers

|

|

|

CanNeed-CAN-5000 Air Meter

|

|

The “CAN-5000 Air Meter “ is for measuring the total air content in carbonated beverages filled in glass and PET bottles and cans. And the air content in the headspace volume. This instrument is recommended for testing air content where greater speed and accuracy is required. It is applicable to various size of bottles and cans.

|

|

|

SCG-200 Seamer clearance Gauge

|

|

CanNeed SCG-200 Seamer clearance Gauge, a quick and accurate way to set up seamers.To measure the roll height off the chuck and the lateral distance between the roll and chuck.

|

|

|

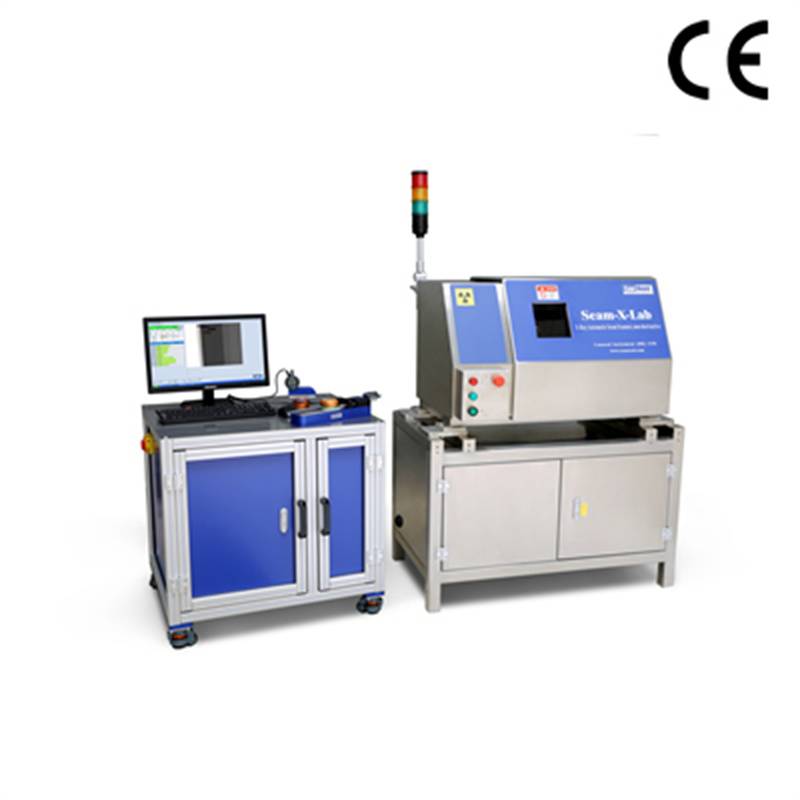

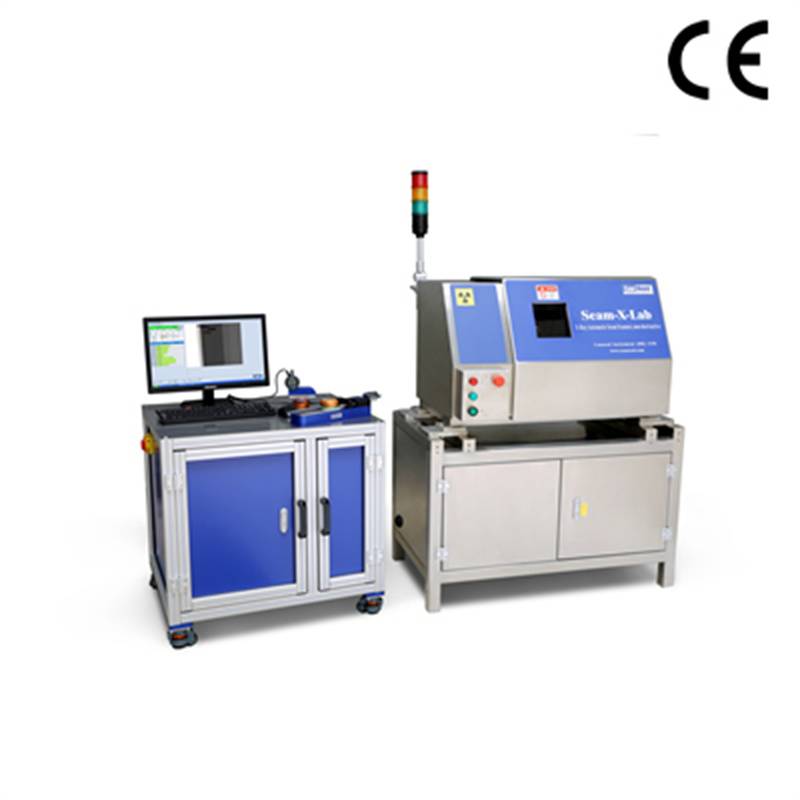

Seam-X®-Lab X-Ray Automatic Seam Scanner(Non-destructive)

|

|

Seam-X®-Lab Automatic Seam Scanner adopts non-destructive measure method to measure the seam dimension, tightness (aluminum and tin composite can excluded), and the actual seam formation.

Measure Items: Seam Length, Body Hook, End Hook, Overlap, %Overlap, Seam Gap, %Body Hook Butting, %End Hook Butting, %Tightness, and the actual seam formation.

It is able to identify if the double seam is fake or not base on the actual seam formation

It’s applicable to measure cans of various materials. Combination of can body and the end can be following: (1) Aluminum & Aluminum; (2) Tin & Tin; (3) Tin & Aluminum.

Seam-X®-Lab can work together with the seam thickness gauge and countersink gauge, to make up a complete measure system for the double seam.

|

|

|

Seam Sight(TM) Full Automatic Seam Monitor

|

The Seam SightTM Full Automatic Seam Monitor is a compact measuring system for quick and accurate automatic seam measurements and storing of seam images.

The seam is positioned manually in front of the camera and is digitised by the computer.

In less than 1 second the Seam SightTM software offers a measurement. The seam length, body hook, end hook, actual overlap, percentage overlap; seam gap, seam thickness and body hook butting% are measured. At the end of the measurement an evaluated seam appears including dimension lines and measured values. This may be stored in computer or printed out on a laserprinter. The values can be stored in a Excel file and are displayed in on-screen if values are within specs.

|

|

|

RPG-100 Roll profile Gauge

|

|

The RPG-100 is able to scan profiles of seaming Rolls and Chucks (or other tooling - including carbide and ceramic tools) easily and quickly. The system can be used for acceptance testing for new seaming rolls or chucks, for quality assurance purposes and for stress analysis. Monitor tooling wear to replace rolls and chucks only when they need to be replaced

|

|

|

CAN-F-125 Pasteurization Temperature Monitor

|

CanNeed CAN-F-125 Sterilization Temperature Monitor (F0 Value Monitor) has been chosen by many beverage and canned food factories.

Applicable to different kinds of sterilization equipments and different place that require temperature monitoring: sterilization kettle (autoclave), Spray sterilization machine, Water sink sterilization machine, warehouse, transportation vehicles, etc.

Applicable to different kinds of products: canned food, beverage, beer, pouch food, jelly, etc.

Applicable to different kinds of packaging: metal cans, glass or PET bottles, pouches, plastic boxes, etc.

|

|

|

CanNeed-DER-4 Digital Enamel Rater

|

|

The CanNeed-DER-4Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

CanNeed-DER-4 is the industry standard. The new CanNeed-DER-4Enamel Rater instrument test the coverage of the enamel coating inside food and beverage cans, aerosol-cans and also different kinds of ends. It displays an index of the amount of metal exposed by incomplete enamel coverage on a clear, easily read digital LED.

|

|

|

CanNeed-CSS-2000 Seam Saw

|

CanNeed-CSS-2000 Seam Saw is a special unit to cut the cans with double seam for inspection.

Sample moving platform is assembled on linear rail with precise cutting effect to ensure that cutting image is very clear when inspecting the seam quality with CanNeed Seam Sight automatic seam monitor.

Linear rail for can moving is installed to make the perfect linear cutting. Configured with extreme hard blade, it is durable and enables the cutting clear without burrs.

|

|

|

CanNeed-CSS-100B Anti-noise Seam Saw

|

|

CanNeed-CSS-100B Anti-noise seam saw is provided with an anti-noise design and a special guide for 2- and 3-piece cans (65 mm dia.). Special seam circular saw with double cut for can double seam inspections. The CanNeed -CSS-100B was specially designed for 2 and 3-piece cans.

The nitrated blades achieve together with the speed of approx. 1.000 r/min. a very plain cut surface. The seam image on VSM 6A Automatic Seam Computer (Video Seam Monitors), and automatic seam measuring systems gets thereby very clear and improves measurement speed and reliability.

|

|

|

CanNeed-STR-100 Seam Stripper

|

|

The CanNeed-STR-100 Can Cover Trim Stripper is designed to quickly and accurately cut can cover trim in place for inspection of cover hook wrinkles and tightness. The CanNeed-STR-100 is also used for boiling tests where a large number of sample cans need to be cut away from the lid to observe the inside of the can.

|

|

|

CVG-200 Canners Vacuum Gauge

|

|

the Canneed "CVG-100 and CVG-200 Canner's Vacuum Gauge", Used to measure the vacuum pressure of seamed cans.

The gauge is placed on top of the can and the piercing needle is forced through the top of the can.

The rubber collar forms a temporary seal to allow for measurement.

|

|

|

CVG-100 Canners Vacuum Gauge

|

|

the Canneed "CVG-100 and CVG-200 Canner's Vacuum Gauge",

Used to measure the vacuum pressure of seamed cans.

The gauge is placed on top of the can and the piercing needle

is forced through the top of the can.

The rubber collar forms a temporary seal to allow for measurement.

|

|

|

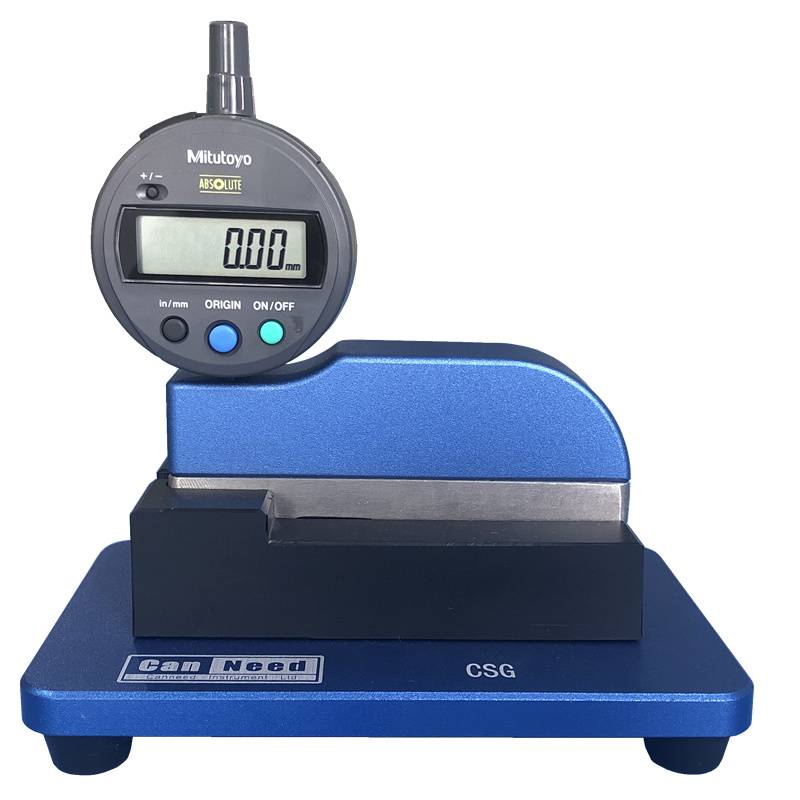

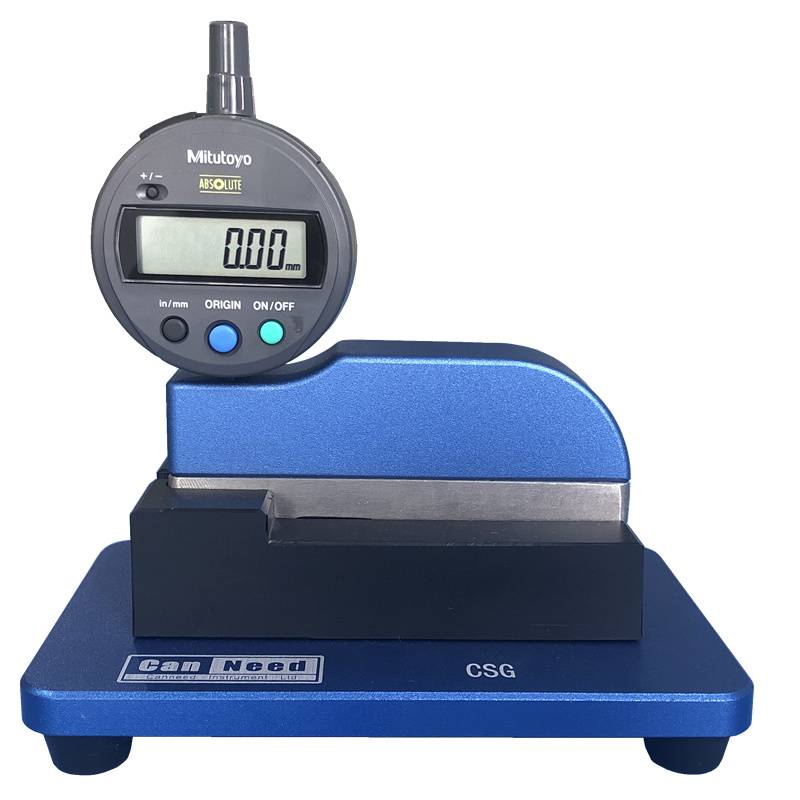

CanNeed-CSG-200 Countersink Gauge (Digital)

|

|

The CanNeed-CSG-200 Countersink Gauge (digital) is a Digital gauge for measuring Countersink depth parameters (the depth of beader of can). With the Mitutoyo 0.01mm Resolution Digital Indicator.

The gauge can be connected to a computer or SPC system via the adapter and cable, so that to avoid the manual recording and personal error. The gauge can also combine with Canneed Seam Monitors and import the measurement data into computer.

|

|

|

CSM-208, CSM-207 Can Seam Micrometers (Fine tuning)

|

CanNeed CSM series Can Seam Micrometers are use for measuring the seam thickness and length. The fine tuning function helps to avoid the deviation caused by over rotation.

CSM-208 is applicable to measure the seam thickness and length of flat bottom straight wall cans.

CSM-207 is applicable to measure the seam thickness and length of aerosol cans and necked-in cans.

|

|

|

CanNeed-CAN-10774 Planer and Shaper Pin Height Gauge

|

|

CanNeed-CAN-10774 The Pin Height Gauge is commonly used in the initial setup of the seamer to ensure double seaming

performance and air removal.

All working surfaces are hardened and accurately ground.

|

|

|

CAN-1050 Can Closing Force Gauge

|

"CAN-1050 Can Closing Force Gauge" is for measuring the force of seaming head of the seaming machine. Advantages:

1. Deduct the scrap rate of the production

2. Shorten the adjusting time, improved production efficiency.

3. Improved the seam quality

|

|

|

SCO Sanitary Can Opener

|

A unique opener used to remove the centre section of the can end while keeping the double seam intact.

Sample can diameter: 40-300 mm 3-piece cans

|

|

|

CanNeed-CST-100 Can Seal Tester (Vacuum mode)

|

|

CanNeed-CST-100 Can Seal Tester (Vacuum mode) is for testing the secure seal of the 3-pc cans by applying the vacuum pressure to see whether the cans leak. It can test 1 (one) round can at each test.

Test method: Fill the sample can with water, cover the transparent platen on the open top, turn on the vacuum pump to generate the negative pressure, and then observe whether there are air bubbles on the can body, if the air bubbles come out continually, that means leakage occurred.

CanNeed-CST-100 is applicable for different can sizes. Please order different platens accordingly.

|

|

|

SST-2 Secure seal tester

|

|

The "canneed SST-2 Secure Seal Tester" is used to

test seal integrity on the glass or plastic containers and cans.

The SST-2 has been designed to address the special needs

of sealing cans and bottles that use aluminum roll-on,

twist crowns, or plastic caps.

The SST-2 operates with compressed air, nitrogen,

or carbon dioxide. By detecting gas leakage, rather than liquid,

the Secure Seal Tester gives more sensitive, accurate readings.

|

|

|

CanNeed-CLT-100 Leak Tester for can

|

|

The “CanNeed-CLT-100 Leak Tester for can “ is used for checking the leakage of 3-piece cans in a water bath. It can test one can in each test.

The test procedure is performed semi-automatically and the CanNeed-CLT-100 is suitable for different sizes of round 3-piece cans.

Testing method: Place the sample can to the platen, the can will be fixed by the magnet disc plate, clampthe can to seal the top, then submerge the can into water and apply pressure to the can.

Observer the can body to see whether there are bubbles come out, if bubbles come out from the can body constantly, that means the sample can leaks. During the testing, operator is able to turn the sample over for easy observing the can top, can bottom, can body and welding line.

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|