|

| |

Product Classification : Metal Cap/Crown Cap/Tab Cap/Screw Cap/Claw Opening Cap

|

|

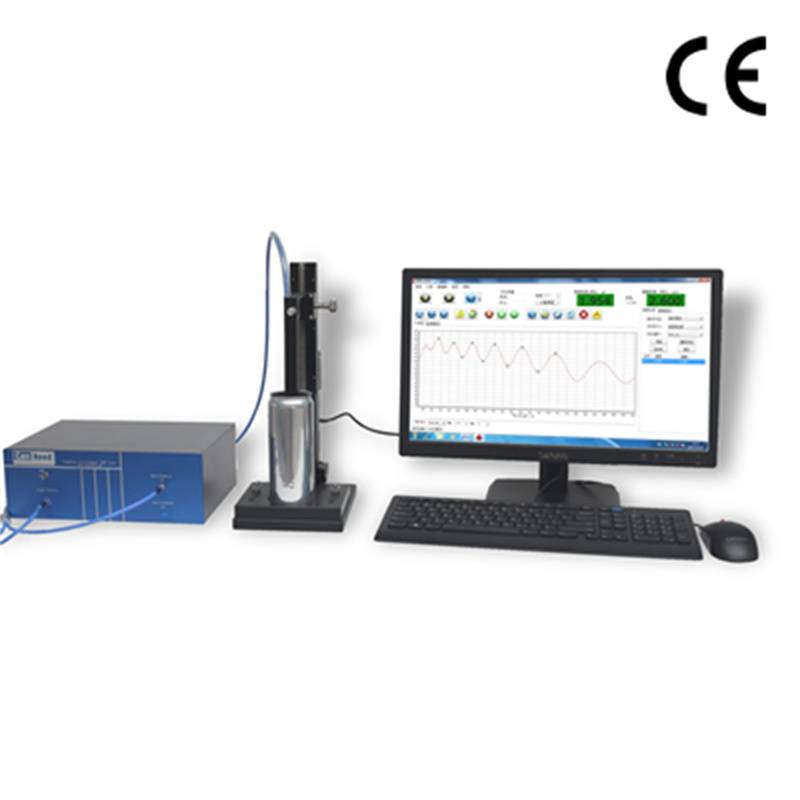

CanNeed-DER-400 Digital Enamel Rater

|

|

CanNeed-DER-400 Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

CanNeed-DER-400 is the industry standard. The new CanNeed Enamel Rater DER-400 instrument test the coverage of the enamel coating inside food and beverage cans, aerosol-cans and also different kinds of ends. It displays an index of the amount of metal exposed by incomplete enamel coverage on a clear, easily read digital LED.

|

|

|

CanNeed-MDER-10 Multi-station Digital Enamel Rater for Ends

|

|

CanNeed-MDER-10 Multi-station Digital Enamel Rater For Ends is used to test the integrity of the inner coating (inner coating density and current value) of the 10 ends at one time. If the inner coating is incomplete and the contents will corrode the metal and affect the quality and storage of the product.

Place ends into the opening hole of ten-hole fixing holders. After the ends are pressed, turn the ten-hole fixing holders over. The current values (mA) of each end as well as the maximum current value and average value can be read out in 4 seconds. If any test failure resulted from bad connection between the contacts, the corresponding position number of the ends will be shown on the screen.

|

|

|

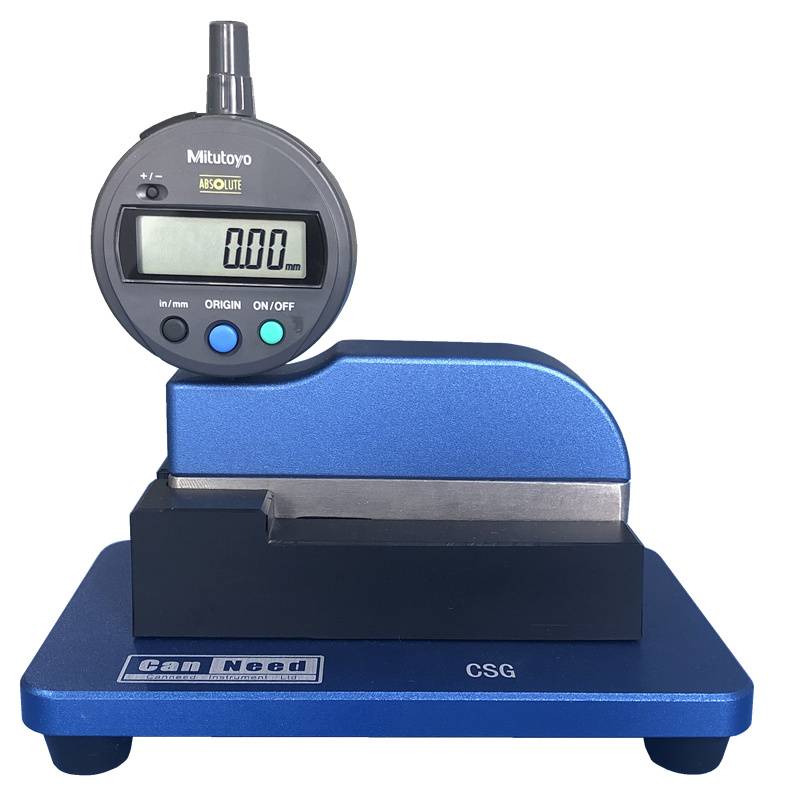

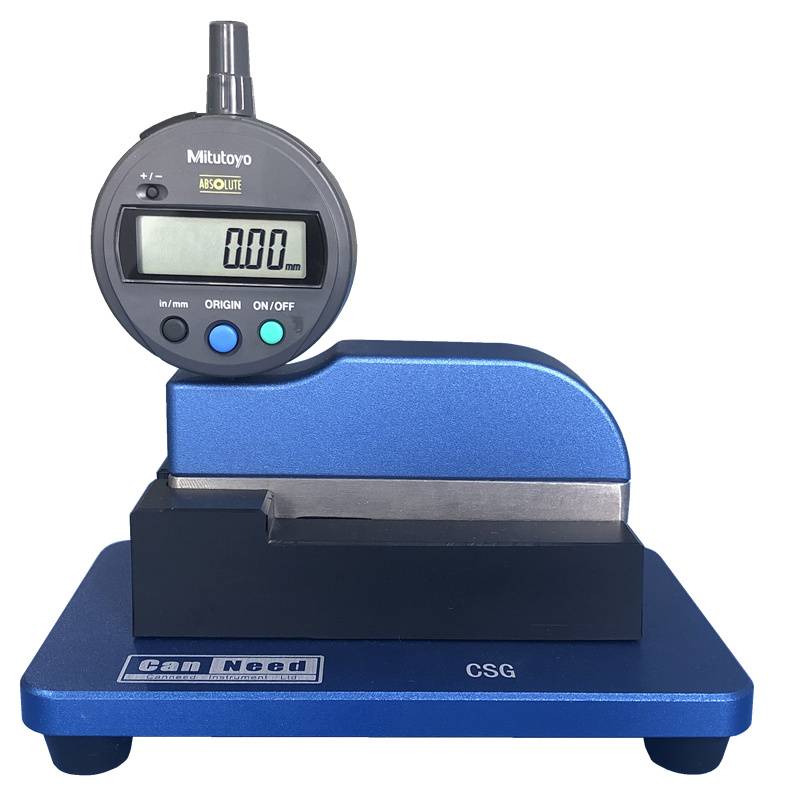

CanNeed-CSG-200 Countersink Gauge (Digital)

|

|

The CanNeed-CSG-200 Countersink Gauge (digital) is a Digital gauge for measuring Countersink depth parameters (the depth of beader of can). With the Mitutoyo 0.01mm Resolution Digital Indicator.

The gauge can be connected to a computer or SPC system via the adapter and cable, so that to avoid the manual recording and personal error. The gauge can also combine with Canneed Seam Monitors and import the measurement data into computer.

|

|

|

CanNeed-AEBT-1000 Automatic Buckle Tester for Loose ends

|

|

CanNeed-AEBT-1000 Automatic Buckle Tester for Loose ends is for testing the exact pressure at which the end buckles. Any end of varying diameter can be tested: change parts are available that can be exchanged within seconds. Three testing modes: “Buckle Test”, “Missile Test”, and “Score Burst Test”. If configured with special clamp, it can make score line cracking test for an end. Suitable for ends of various sizes. User should choose the clamp accordingly.

|

|

|

CanNeed-PTT-400 Pop & Tear Tester

|

|

CanNeed PTT-400 Pop & Tear Tester was developed for testing different kinds of easy open ends. It can measure the Pop & Tear force, ring rotary force and ring detaching force.

Applicable to various types of ends, here to be shown 7 types: RP / SOT / EO / OVAL / FSE / SNAP and ALUFIX. It’s also suitable for sample ends from types of 113 to 603 (round ends). Oval or rectangular ends needs customized clamp for test. Oval ends diameter or longer length of rectangular should not be longer than 163 mm.

|

|

|

CanNeed-DT-100 Thread Depth Gauge

|

|

CanNeed-DT-100 Thread Depth Gauge is used to measure the thread depth on the caps of aluminum bottle cans, which can make the bottle can closure fit better with the caps.

The gauge assembles with a digital Mitutoyo meter and a calibration platform.

|

|

|

CanNeed-EMS-200 Multiple Lid Measurement Station

|

|

CanNeed-EMS-200 Multiple Lid Measurement Station is for measuring the End Curl Outer Diameter, End Curl Height, Countersink and Thimble Depth. The end countersink is the height of countersink position minus the thickness of plate.

Place the ends on the testing platform, select the measure points, then press “start”. The four pneumatic controlled sensors will start to measure the sample ends automatically at the same time. The sample ends will be rolled automatically to change the measure points. For every circle, the amount of measure points can be set from 1 to 50. Measurement results can be exported by the RS232 data wire. Calibrate by the standard gauge and controlled by the touch-screen PLC system.

Use the CND_EMS 1.0 professional software to collect and save the measurement data into the database, helps on the statistics and generating reports.

|

|

|

CanNeed-SMM-400 Score Measure Microscope

|

|

CanNeed-SMM-400 Score Measure Microscope adopted the microscope technology to measure the score depth and residue of can ends. The measurement is accomplished by the focusing of microscope, if the microscope gets a very clear image, that means the focusing is correct, the height changing of the focus of microscope shows the depth of the end score. The diameter of nether measuring needle is very small, focusing on the top of the nether measuring needle, zero the indicator, place the sample end onto the platen, adjust the focus until gets the clear groove bottom image of the end score, then gets the score residue. Place the sample onto the platen, focusing on the surface of sample ends (edge of the score), zero the indicator, adjust the focus , when the clear groove bottom image displays on the screen, then gets the depth of score.

|

|

|

CanNeed-ELT-100 Leak Tester for End

|

|

The “CanNeed-ELT 100 Leak Tester for End” is used to determine the pressure at which ends buckle. This tester is also used to test for pin hole leaks in the tab score and rivet area.

There are two intended testing purpose for CanNeed-ELT-100 Leak Tester for End:

1. To determine the pressure at which ends buckle

2. To test for pin hole leaks in the tab score and rivet area

|

|

|

CanNeed-TT-200 Torque Tester

|

Applications: Food-industry / Cosmetic/ Pharmaceutical / Chemical / Metrology

CanNeed-TT-200 Torque Tester is a professional equipment which is used to test the caps’ “capping torque”and “songaila torsion “for bottled products.It is industry standard with excellent performance.Users can option software.

|

|

|

CanNeed-EBT-400 Buckle Tester for Loose Ends (With Missile Test)

|

|

The CanNeed-EBT-400 Buckle Tester for Loose ends is for testing the exact pressure at which the end buckles. Any end of varying diameter may be tested: change parts are available that can be exchanged within seconds. Three testing modes: “Buckle Test”, “Missile Test”, and “Score Burst Test”.

|

|

|

CanNeed-PTT-300 Pop & Tear Tester

|

|

CanNeed-PTT-300 Pop & Tear Tester was developed for testing different kinds of easy open ends. It can measure the Pop & Tear force, ring rotary force and ring detaching force.

Adopted 7 different testing modes: RP / SOT / EO / OVAL / SNAP / RF and RPP. OVAL mode can test both OVAL and FSE ends. SNAP mode can test both SNAP and ALUFIX ends. VF mode is for ring rotary force measurement while RPP mode is for ring detaching force measurement.

Applicable to various types of ends, here to be shown 7 types: RP / SOT / EO / OVAL / FSE / SNAP and ALUFIX. It’s also suitable for sample ends from types of 113 to 211 (round ends). Oval or rectangular ends needs customized clamp for test. Oval ends diameter or longer length of rectangular should not be longer than 163 mm.

|

|

|

CanNeed-PNR-E200 Pressure No Return Tester for Ends

|

|

The CanNeed-PNR-E200 Pressure No Return Tester for Ends can measure the PNR value (Plastic Deformation) and the buckle value of the ends. During the whole pressurization process, use the micrometer to track and measure the deformation amount, generate the curve through the software and analyze the correlation between pressure and deformation amount of the ends.

|

|

|

CanNeed-FSF-100 Tinplate Holder

|

|

The CanNeed FSF-100 Tinplate Holder is used together with the CanNeed-DER-400 Digital Enamel Rater and the vacuum device to test the integrality of the enamel coating inside the tinplate.

|

|

|

CanNeed-OCTG-1000 Optical Coating Thickness Gauge

|

|

CanNeed-OCTG-1000 Coating Thickness Gauge is used to measure the coating thickness in real time, save time and improve the quality of the product. Non-contact optical measurement technology is applied to product development, laboratory quality control and online production control. In the solar energy industry, optical coating industry, food packaging,as well metal packaging, are very good choice to improve the surface quality of products: appearance, adhesion, corrosion resistance, abrasion resistance, scratch resistance.

|

|

|

CanNeed-OCTG-2000 Coating Thickness Gauge

|

|

CanNeed-OCTG-2000 Coating Thickness Gauge is used to measure the coating thickness in real time, save time and improve the quality of the product. Non-contact optical measurement technology is applied to product development, laboratory quality control and online production control. In the solar energy industry, optical coating industry, food packaging,as well metal packaging, are very good choice to improve the surface quality of products: appearance, adhesion, corrosion resistance, abrasion resistance, scratch resistance.

|

|

|

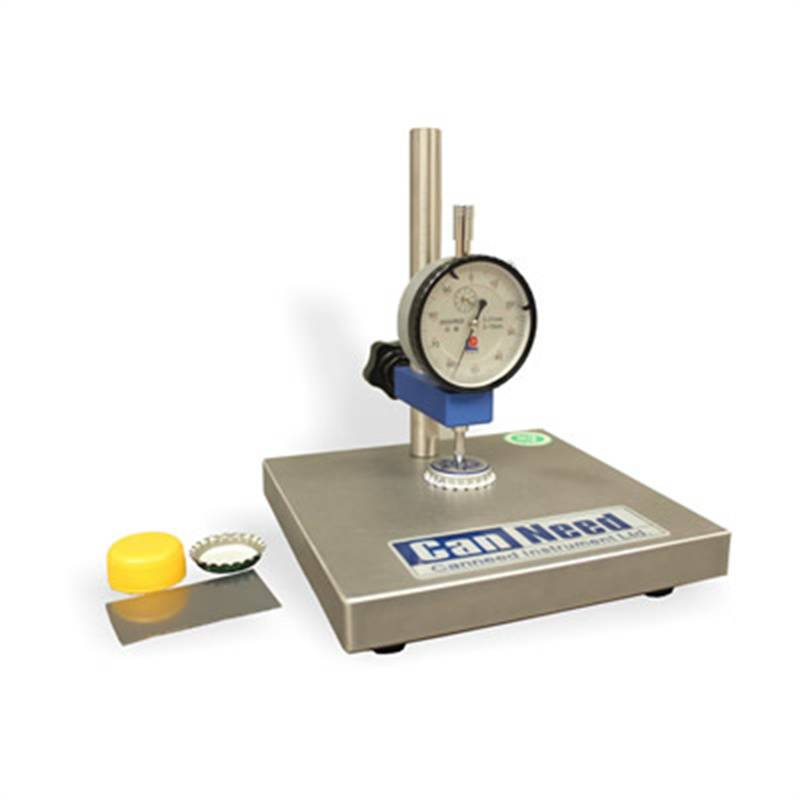

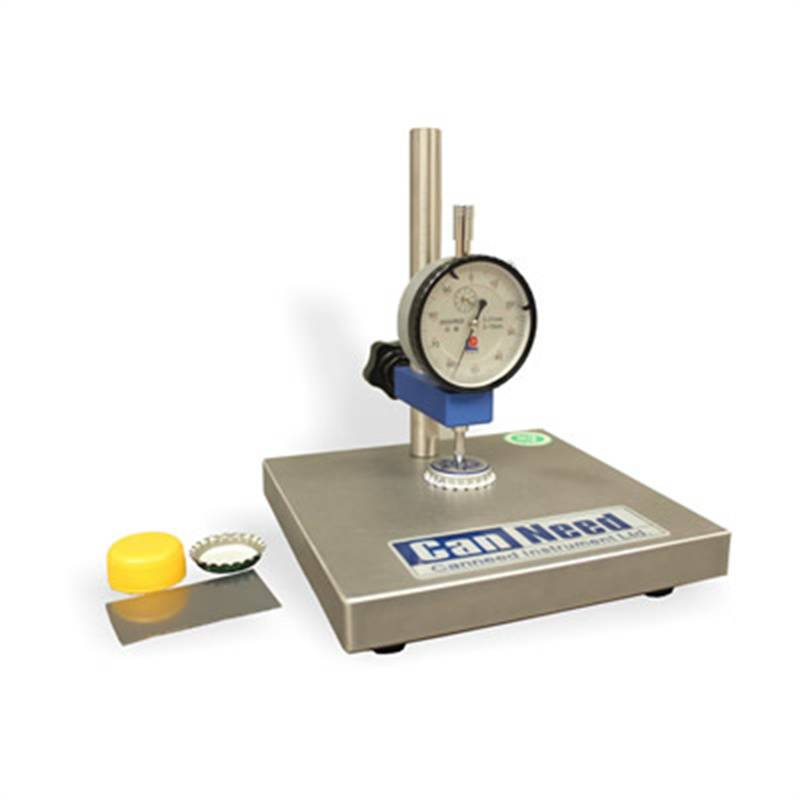

CanNeed-HDY Crown Height & Thickness Tester

|

The “CanNeed-HDY Crown Height & Thickness Tester” has fine designed testing base, the crown height and thickness are measured by the dial indicator.

The CanNeed-HDY has widely used in crown factories, beer and beverage factories.

The CanNeed-HDY is made of stainless steel.

|

|

|

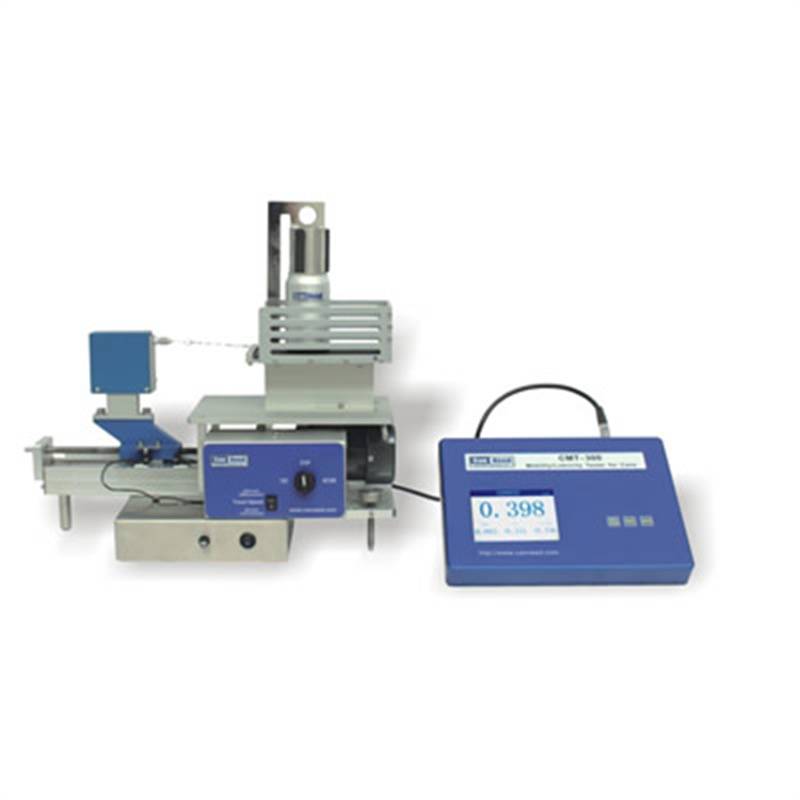

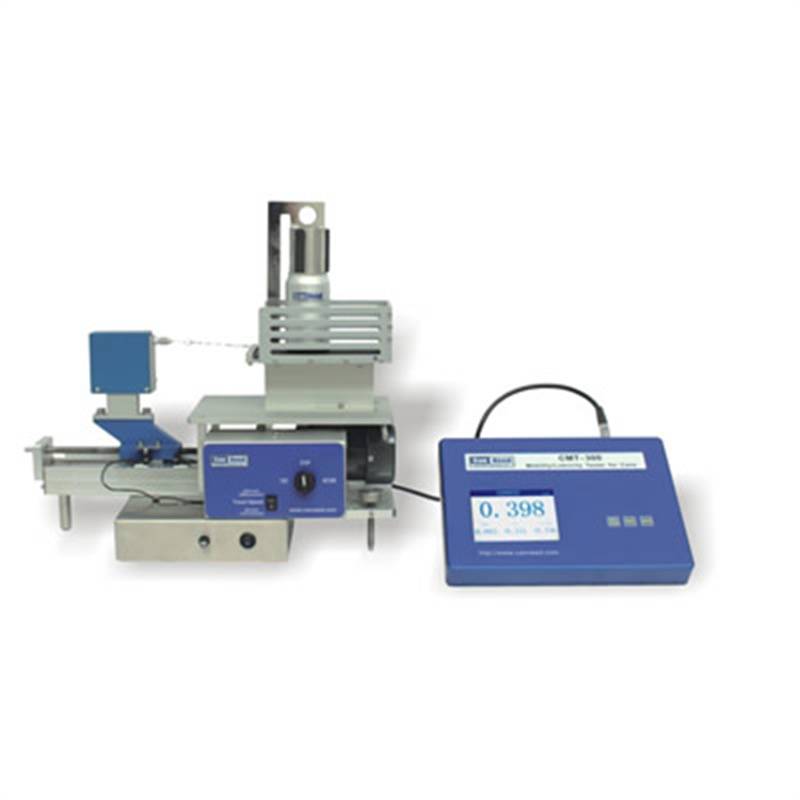

CanNeed-CMT-300 Mobility/Lubricity Tester for Cans (Digital)

|

|

CanNeed-CMT-300 Mobility / Lubricity Tester for Cans is for measuring the coefficient of sliding friction of can body and bottom. It can also measure the coefficient of sliding friction of blanks.

Install the corresponding clamp and place the sample on the clamp, then put the bob-weight unit on the sample. Pull the bob-weight and the indicator will display the coefficient of sliding friction.

|

|

|

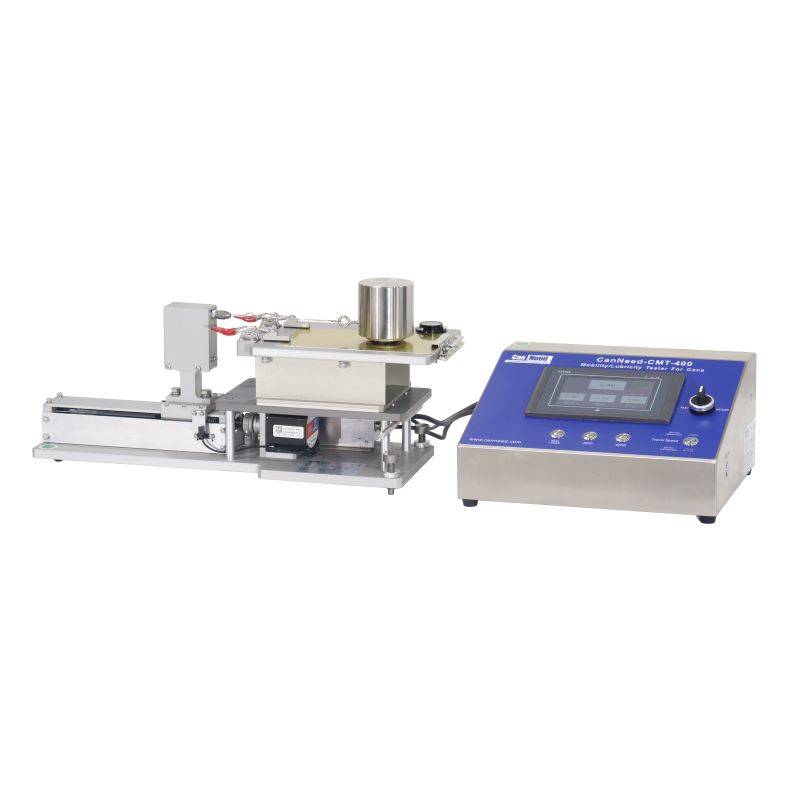

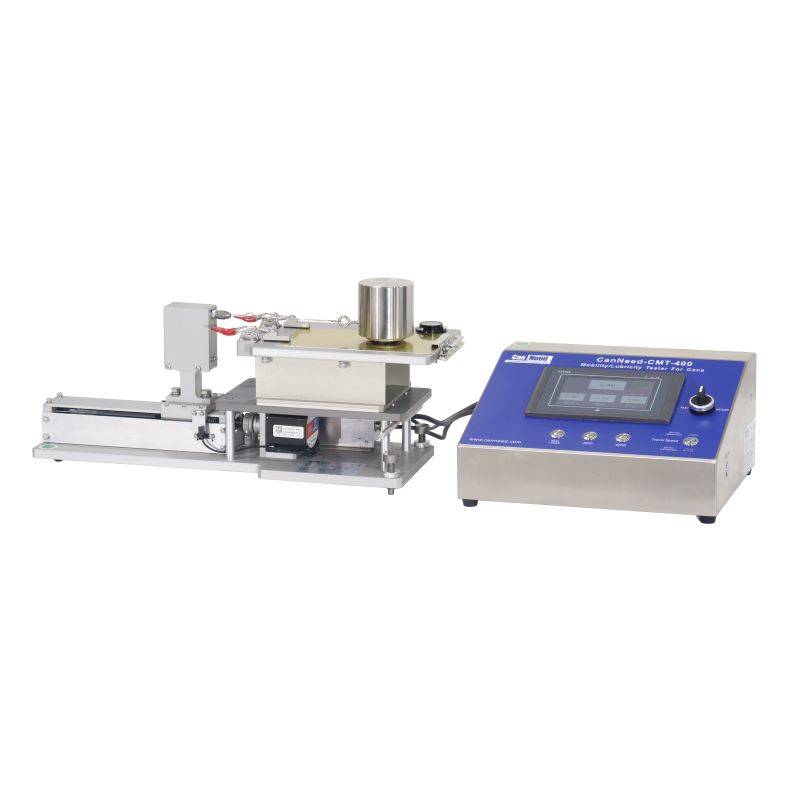

CanNeed-CMT-400 Mobility / Lubricity Tester for Cans (Digital)

|

|

CanNeed-CMT-400 Mobility / Lubricity Tester for Cans is for measuring the coefficient of sliding friction of can body and bottom. It can also measure the coefficient of sliding friction of blanks.

|

|

|

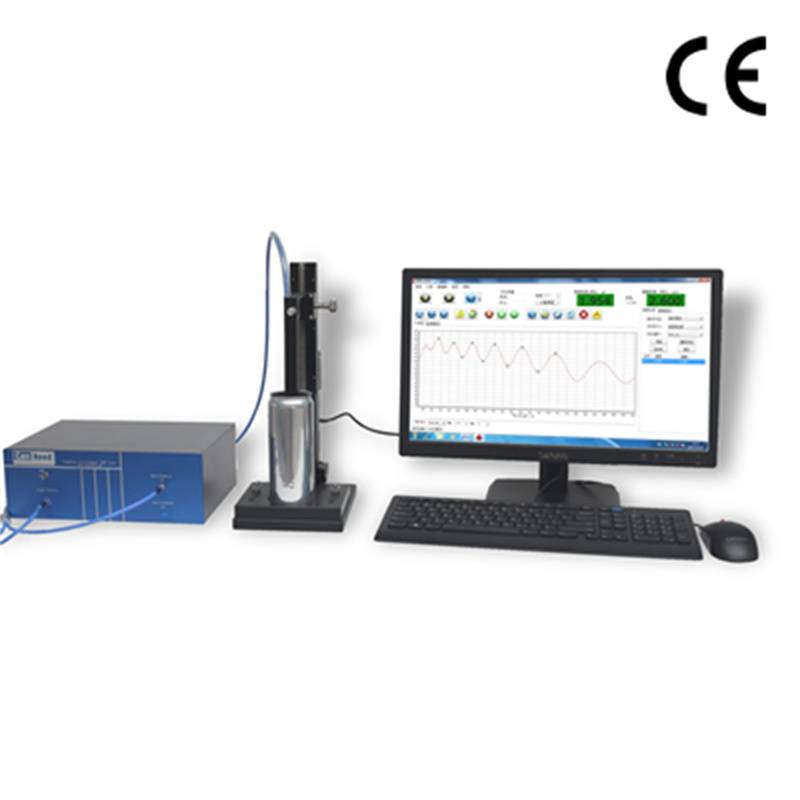

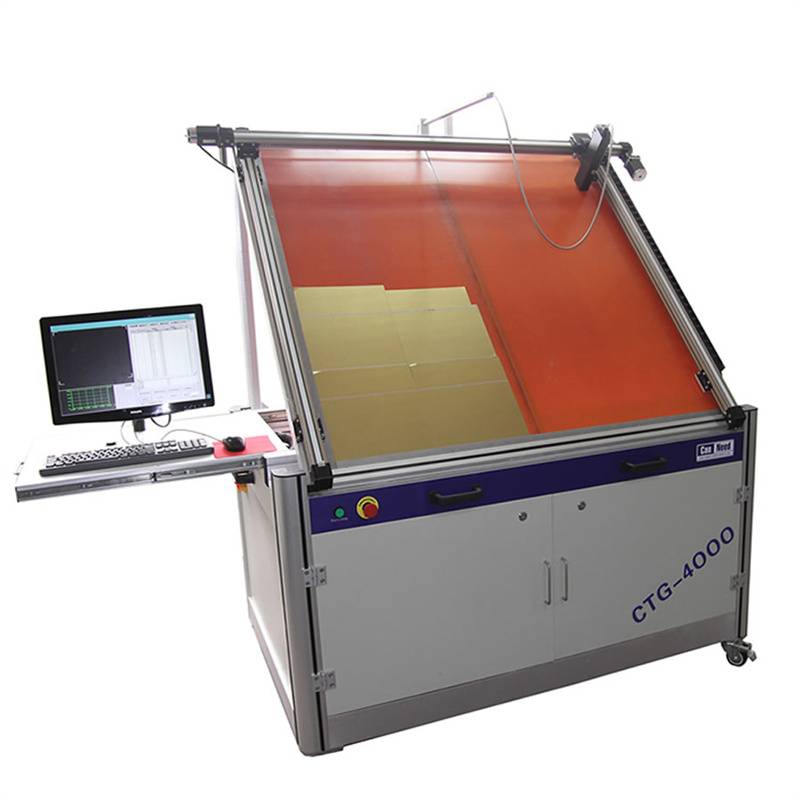

CanNeed-EPS-200 End Profile System

|

|

CanNeed-EPS-200 End Profile System is used to measure the end dimensions. It is with excellent performance by adopting precise optics measuring technology, measuring the end dimensions precisely.

CanNeed-EPS-100 adopts precise optics measuring technology, takes the place of destruction measuring methods. The destruction measuring methods are not only inaccurate and time-consuming, but also get different results because of different operators. The inaccuracy of end dimensions usually cause to such double seam defects as fault sealing, bearing cover and false sealing and so on. With CanNeed-EPS-200 End Profile System, it can easily measure the entire profile parameters of ends.

|

|

|

CanNeed-OCTG-4000 Thickness Gauge and Wet Film Thickness

|

|

Measure real-time thickness of coating and welt film.Save time and improve quality

Deliver real-time results on single or dual layers

Adopt non-contact optical technology,applicable for R&D,QC,and on-line production

In solar energy,optical filming,food packaging and metal packaging industries, improve surface quality such as appearance, adhesion, corrosion resistance, wear resistance, and scratch resistance.

|

|

|

CND-SST-3 Secure Seal Tester

|

|

The "CND-SST-3 Secure Seal Tester" is used to test seal integrity on the glass or plastic containers and cans. The SST-2 has been designed to address the special needs of sealing cans and bottles that use aluminum roll-on, twist crowns, or plastic caps. The SST-2 operates with compressed air, nitrogen, or carbon dioxide. By detecting gas leakage, rather than liquid, the Secure Seal Tester gives more sensitive, accurate readings.

SST-3 is constructed from anodized aluminum, stainless steel, and plastic materials. The tester's rugged construction withstands production line abuse, yet is accurate enough for laboratory use.

|

|

|

CanNeed-PTT-C400 Pop & Tear Tester for Cap

|

|

|

|

|

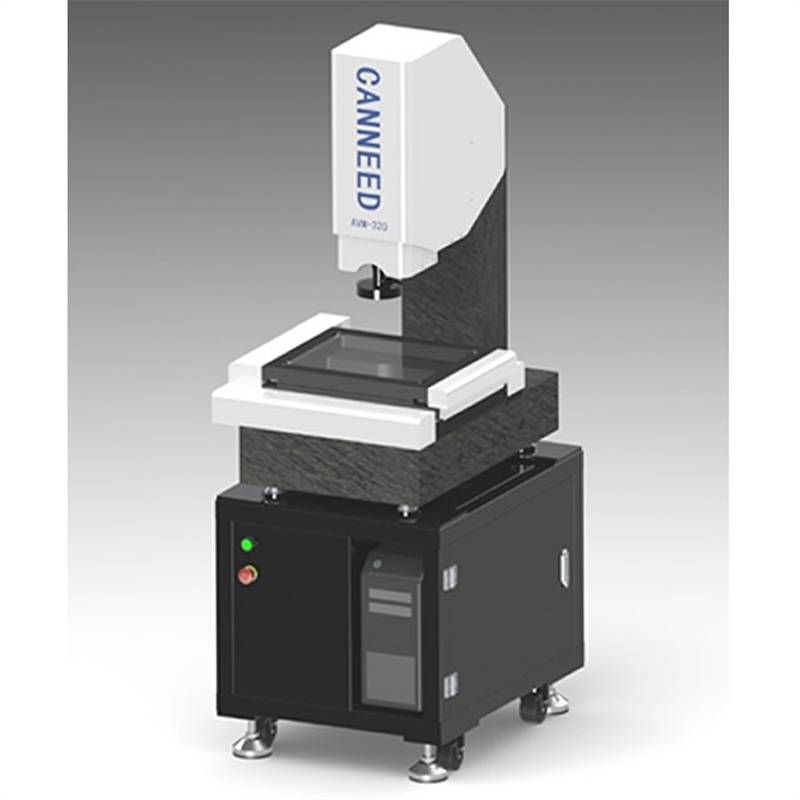

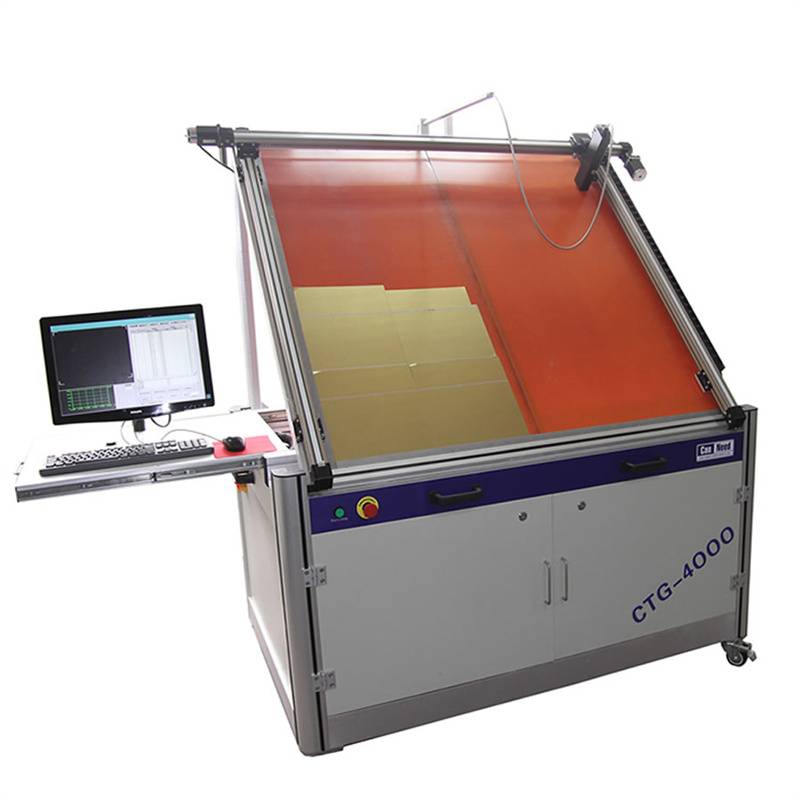

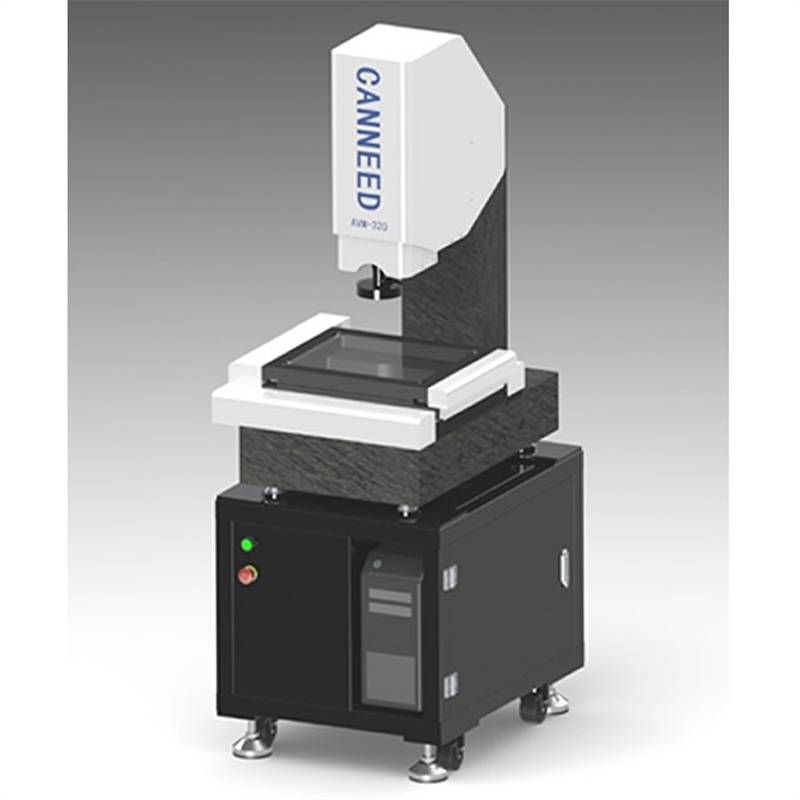

CanNeed-AVM-320

|

|

|

|

|

CanNeed-CCST-100 Crown Cap Secure Seal Tester

|

|

The “CCST-100 Crown Cap Secure Seal Tester” is used to test the air tightness of crown caps. The tester is made of stainless steel, so that ensure its durability.

|

|

|

CanNeed-DER-4 Digital Enamel Rater

|

|

The CanNeed-DER-4Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

CanNeed-DER-4 is the industry standard. The new CanNeed-DER-4Enamel Rater instrument test the coverage of the enamel coating inside food and beverage cans, aerosol-cans and also different kinds of ends. It displays an index of the amount of metal exposed by incomplete enamel coverage on a clear, easily read digital LED.

|

|

|

BLT-100 Tumbling Tester for Crown Closures

|

|

The CanNeed “BLT-100 Tumbling Tester for Crown Closures“ is for evaluating the abrasion resistance of crown closures.

Functional description:

The crown closures are tumbled over top for a certain time to cause abrasion. This test simulates the condition of unsorted storage during transport and feeding.

Advantages:

Standardized abrasion test for crown closures

Standardized tumbling speed and Adjustable duration

|

|

|

CanNeed-CAN-7001/7002 CO2 Tester and Pressure Tester

|

|

CanNeed-CAN-7001, CAN-7002 CO2 Tester and Pressure Tester is for measuring the CO2 content in carbonated beverages filled in glass and PET bottles or cans. It is designed according to ASBC Theory of American Society of Brewing Chemists, corresponding to “GB/T 4928 – 2001 Brewing Analysis Methods” and “GB/T 10792 – 1995 Carbonated Beverage Analysis Methods”. Therefore, the machine is widely used by Quality and Technical Supervision Bureau and beverage enterprises.

It is applicable to the bottles or cans with different sizes. After the sample is pierced, the pressure is read on the pressure gauge as soon as the equilibrium pressure is achieved. The CO2 content is determined by means of the CO2 slide rule or temperature/pressure relationship charts.

|

|

|

GNG-100 ‘Go-no-Go’ Gauge

|

Quality control gauges for checking the threaded tops of glass and plastic containers. Checks the threads, outside diameter, spacing, etc.

Comb. Finish Gauge 28mm-PCO-1816 PET

Comb. Finish Gauge 28mm Pet/28-969-1716

Comb. Finish Gauge 38mm Glss/38-1663

Comb. Finish Gauge 38mm Pet/38-1690

Comb. Finish Gauge 28mm Glass/28-1650RE

Comb. Finish Gauge 28mm-PCO-1810 PET

Comb. Finish Gauge 28BPF

|

|

|

FHS-100 Fill Height Syringe

|

Used to adjust water level in a bottle to a pre-determined fill height.

For checking content of bottle using the fill height Syringe accurately and quickly.

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|