|

| |

Product Classification : Can Making----End and Shell Evaluation

|

| Total page:1

Current page:1 Total records:19 |

First | Previous | Next | Last

|

|

|

LaserScore-300 Automatic EOE Score Residue and Progression Measure System

|

The CanNeed LaserScore-300 Automatic EOE Score Residue and Progression Measure System (Non-contact)

Inspecting the thickness of End score residue and convex progression automatically

Based on laser technology and automatic visual positioning technology, Canneed’s LaserScore-300 used to inspect EOE score residue and rivet convex progression automatically. LaserScore-300 has 2 work positions, each position adapts to inspect 202, 206 and 209 EOE.

|

|

|

SMM-300 Score Measure Microscope (PC Module)

|

|

The CanNeed "SMM-300 Score Measure Microscope" adopted the microscope technology to measure the score depth and residue of can ends. Equip with the high definition CCD camera system, locating done by displaying the clear groove bottom image of the end score on the screen, the measurement data is accurate, reliable and reproducible. The end sample to be clamped on a two-dimensional platen, which is much easier for locating and measurement. The fine digital indicator which has a resolution of 1µm (0.001mm).

|

|

|

AEPS-100 Automatic End Profile Systems

|

|

CanNeed-AEPS-100 Automatic End Profile System is used to measure the end dimensions. It is with excellent performance by adopting precise optics measuring technology, measuring the end dimensions precisely.

The inaccuracy of end dimensions usually cause to such double seam defects as fault sealing, bearing cover and false sealing and so on. It is hard to measure the profile dimensions of ends without CanNeed-AEPS-100.

CanNeed-AEPS-100 takes the place of destruction measuring methods. The destruction measuring methods are not only inaccurate and time-consuming, but also get different results because of different operators.

Adopting precise optics measuring technology, CanNeed-AEPS-100 can measure all important parameters of ends.

|

|

|

MDER-10 Multi-station Digital Enamel Rater for Ends (10 Stations)

|

|

In order to meet the needs of testing several ends at one time, CanNeed designed MDER-10 and MDER-20 Multi-station Digital Enamel Rater for Ends. MDER-10 can finish testing the current of 10 ends in 4 seconds. If connected with two ten-hole fixing holders, it can test 10 ends at one time. The diameters of ends are 50-99mm.

|

|

|

CTG-HP Hover Probe

|

|

The CanNeed CTG-HP Hover Probe is combined with CTG-300/CTG-310 Coating Thickness Gauge to test the lacquer film coating thickness and weight per unit area.

|

|

|

CanNeed-CTG-310 Coating Thickness Gauge

|

|

CanNeed-CTG-310 Coating Thickness Gauge is used to test the coating thickness(coating weight per unit area, g/m2). When equipped with “Hover Probe”, it can measure the coating thickness of plate sheets. When equipped with can body testing clamp, it can test the coating thickness of can body.

Use standard coating plate (sample with known weight, g/m2) calibration equipment to test different

types of coatings. Test result and coating type number will display on the screen and the data will be output to PC with RS232.

|

|

|

CanNeed-DER-400 Digital Enamel Rater

|

|

CanNeed-DER-400 Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

CanNeed-DER-400 is the industry standard. The new CanNeed Enamel Rater DER-400 instrument test the coverage of the enamel coating inside food and beverage cans, aerosol-cans and also different kinds of ends. It displays an index of the amount of metal exposed by incomplete enamel coverage on a clear, easily read digital LED.

|

|

|

CanNeed-DER-4 Digital Enamel Rater

|

|

The CanNeed-DER-4Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

CanNeed-DER-4 is the industry standard. The new CanNeed-DER-4Enamel Rater instrument test the coverage of the enamel coating inside food and beverage cans, aerosol-cans and also different kinds of ends. It displays an index of the amount of metal exposed by incomplete enamel coverage on a clear, easily read digital LED.

|

|

|

PTT-300 Pop and Tear Tester

|

|

The CanNeed "PTT-300 Pop & Tear Tester" was developed for testing different kinds of easy open ends.

Applicable to 7 different types of ends: RP / SOT / EO / OVAL / FSE / SNAP and ALUFIX.

Adopted 5 different testing modes: RP / SOT / EO / OVAL and SNAP.

Operators just need to hook the ring and press "test" button, then the PTT-300 will do the test automatically. During the testing process, the microprocessor will monitor and record the max. Pop and Tear force. With different sizes of the clamps, it is able to test different sizes of ends.

|

|

|

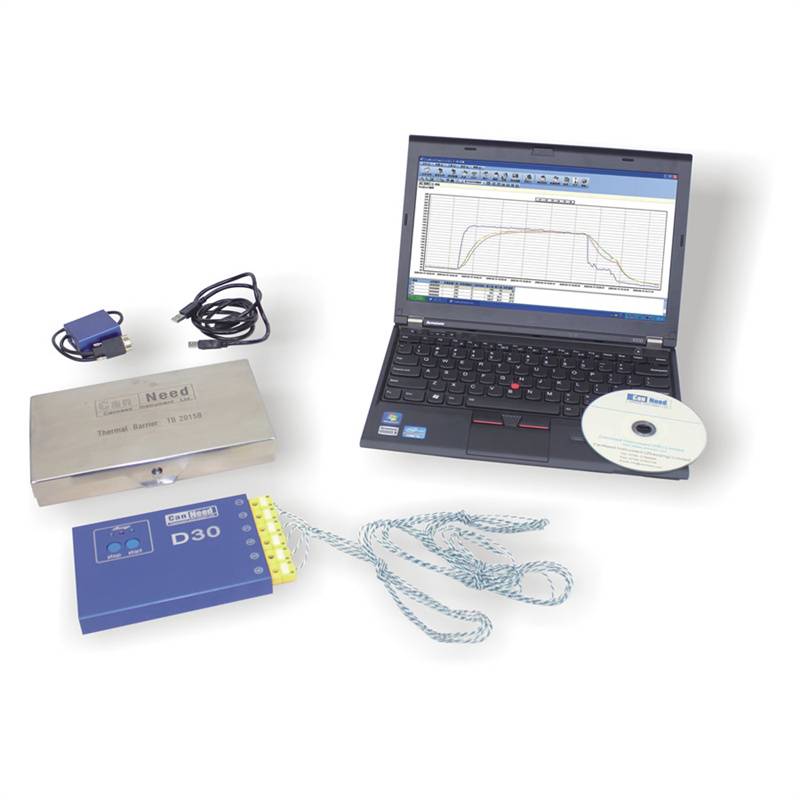

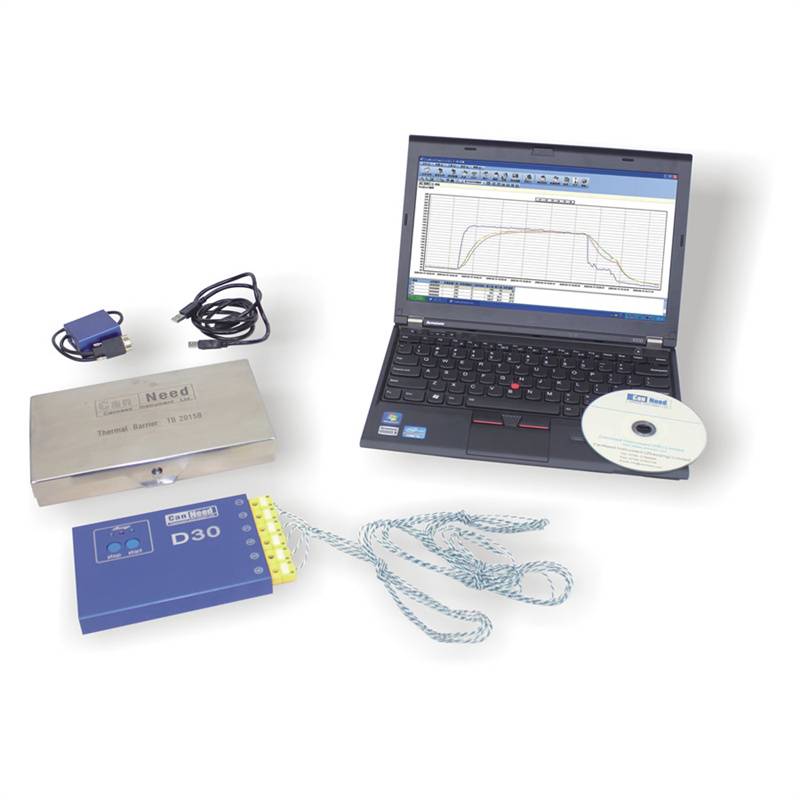

CanNeed-CND-TRK-300 Oven Temperature Tracker

|

|

The “CanNeed-TRK-300 Oven Temperature Tracker” is a professional oven temperature curve inspection system for the coating industry, it is including the data logger, heat insulation case, software (Chinese / English) and thermocouples.

"CanNeed-TRK-300 Oven Temperature Tracker” is use to pass through the oven with the solidifying products, and record down the real temperature during the process. The logger is in the centre of the system. Heat insulation case is for protecting the logger from over heat by the oven. When passing through the oven, the CanNeed-TRK-300 Oven Temperature Tracker will record down the real time temperature of the solidifying products through the 5 thermocouples which were connected to the products, and one thermocouple is for recording the air temperature of the oven. After the recording process was finished, use the CND_TRK Software to analyze the temperature data and generate the detail reports.

|

|

|

EMS-200 Multiple Lid Measurement Station

|

The CanNeed EMS-200 Multiple Lid Measurement Station is for measuring the End Curl outer diameter, End Curl height and Countersink.

Place the ends on the testing platform, select the measure points, then press "start". The three pneumatic controlled sensors will start to measure the sample ends automatically at the same time. The sample ends will be rolled automatically to change the measure points. For every circle, the amount of measure points can be set from 1 to 50.

Measurement results can be exported by the RS232 data wire. Calibrate by the standard gauge and controlled by the touch-screen PLC system.

|

|

|

EMD-400 End Measure Desk

|

|

The CanNeed "EMD-400 End Measure Desk" was developed according to the long-term practical experience, it can be used next to the production line or in the laboratory.

The EMD-400 measures the End Curl Height, Curl Diameter, End Curl Width and Countersink. It is equipped with Mitutoyo digital indicator. If purchased the adapter and cable, the gauge can be connected to a computer or SPC system for data collection.

|

|

|

EBT-300 Buckle Tester for Loose Ends(with Missile Test)

|

|

The CanNeed "EBT-300 Buckle Tester for loose ends" is for testing the exact pressure at which the end buckles. Any end of varying diameter may be tested: change parts are available that can be exchanged within seconds. Three testing mode, "Buckle Test", "Missile Test", and "Score Burst Test".

|

|

|

PNR-E100 Pressure No Return Tester for Ends

|

|

The CanNeed "PNR-E100 Pressure No Return Tester for Ends" can measure the PNR value (Plastic Deformation) and the buckle value of the ends. During the whole pressurization process, use the micrometer to track and measure the deformation amount, generate the curve through the software and analyze the correlation between pressure and deformation amount of the ends.

|

|

|

CEBT-100 Buckle Tester for Can and End

|

The “Canneed CEBT-100 Buckle Tester for Can and end” determines the exact pressure at which the Can and End begins to buckle. With 4 measuring mode:

|

|

|

ELT-100 Leak Tester for End

|

The "Canneed model ELT-100 Leak Tester for End "is used to determine the pressure at which ends buckle. This tester is also used to test for pin hole leaks in the tab score and rivet area.

The ELT-100 applies high pressure air to the product side of and end until the end fails. Leaking spots are made visible by revealing bubbles in the water bath. The failure of an end occurs either when the end buckles or when it starts leaking, leakage is generally caused by faulty scores or rivets.

|

|

|

ZME-1220 Digital End Blank Gauge for Scroll Cut

|

ZME-1220 is to test the following items of the end blank:

1) Length

2) Parallelism

3) Perpendicularity (angle)

4) Reference points

* Simple operation with the help of a incremental ruler/ fine measuring gauge combination and digital indicators

* Accurate, repeatable, user-independent results

* Continuously displaying readings

|

|

|

VRM-4C Video Rivet Monitor

|

|

The CanNeed VRM-4C Video Rivet Monitor is a video camera system to observe and evaluate the rivet's profile images of the ends. The end is cutting through the rivet by the low speed saw LSS-100, the rivet is positioned manually at front of the camera. The rivet profile's images are displaying on the screen. It also can be used with a PC to be a compact measuring system. Within VRM Image Archive Software, the computer offers a measurement. This should be sorted in the computer or printed out on a laserprinter.

|

|

|

LSS-100 Low Speed Saw

|

|

The "Canneed LSS-100 Low Speed Saw" is for cut the End rivet to observe and evaluate the rivet profile images of ends. It work with the "Canneed VRM 3A Video Rivet monitor".

The end is cut through the rivet by the LSS-100 Low Speed Saw, the rivet is positioned manually in front of the camera. The rivet profile images display on the display.

|

|

| Total page:1

Current page:1 Total records:19 |

First | Previous | Next | Last

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|