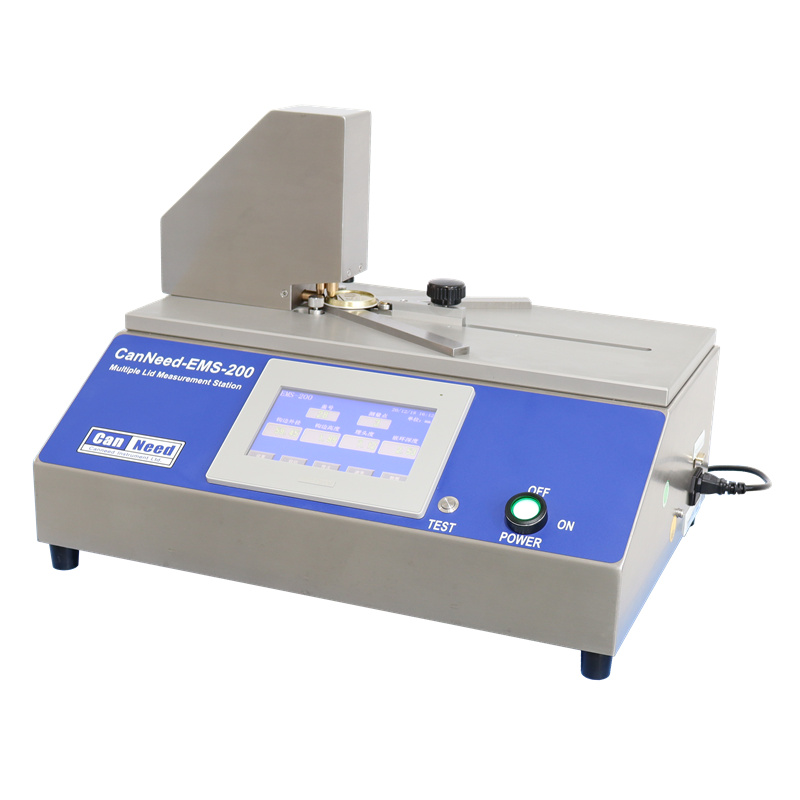

CanNeed-EMS-200 Multiple Lid Measurement Station is for measuring the End Curl Outer Diameter, End Curl Height, Countersink and Thimble Depth. The end countersink is the height of countersink position minus the thickness of plate.

Place the ends on the testing platform, select the measure points, then press “start”. The four pneumatic controlled sensors will start to measure the sample ends automatically at the same time. The sample ends will be rolled automatically to change the measure points. For every circle, the amount of measure points can be set from 1 to 50. Measurement results can be exported by the RS232 data wire. Calibrate by the standard gauge and controlled by the touch-screen PLC system.

Use the CND_EMS 1.0 professional software to collect and save the measurement data into the database, helps on the statistics and generating reports.

粤公网安备44120302000118号

粤公网安备44120302000118号