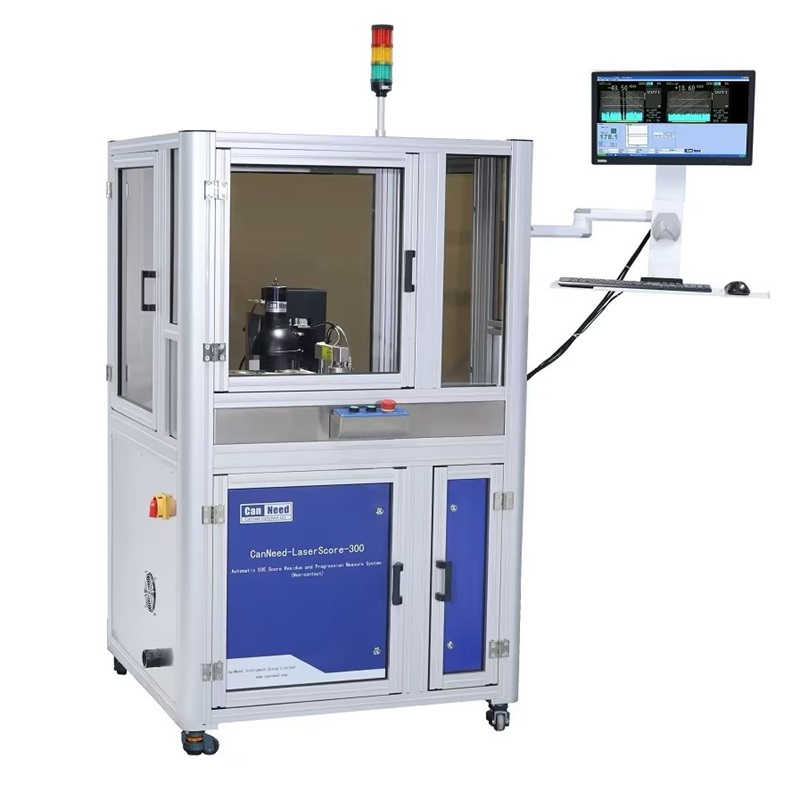

Based on laser technology and software analysis, the “CanNeed-Laserscore-200 Score Residue Measure System” is a non-destructive system for measuring the residual score on Ends. It combines ease of use and reliability with excellent repeatability and accuracy. The end clamp is equipped in a 360° rotary two-dimension linear guide working platform. It matches the ends, convenient to position and measure.

Measure principle: The position of reflected light on the sensor changes corresponding to the change of

"the score depth”. Through inspecting this position change, it can measure the score depth of ends. The CanNeed-LaserScore-200 system uses two laser sensors, which are installed on the top side and underside of the can end – the reflect Laser beam to the sensors depending on the depth of the surface. The score depth and residue are calculated based on the calibration table and the actually performed measurement.

It takes about 5 seconds to do a measurement. It is simple to operate the laser measure software!

粤公网安备44120302000118号

粤公网安备44120302000118号