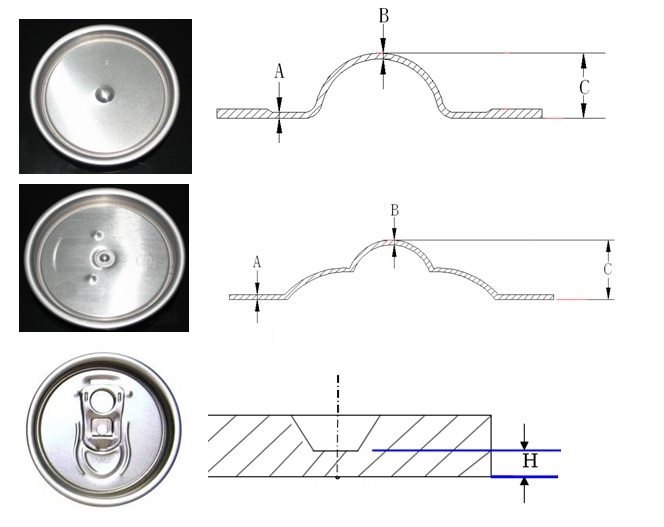

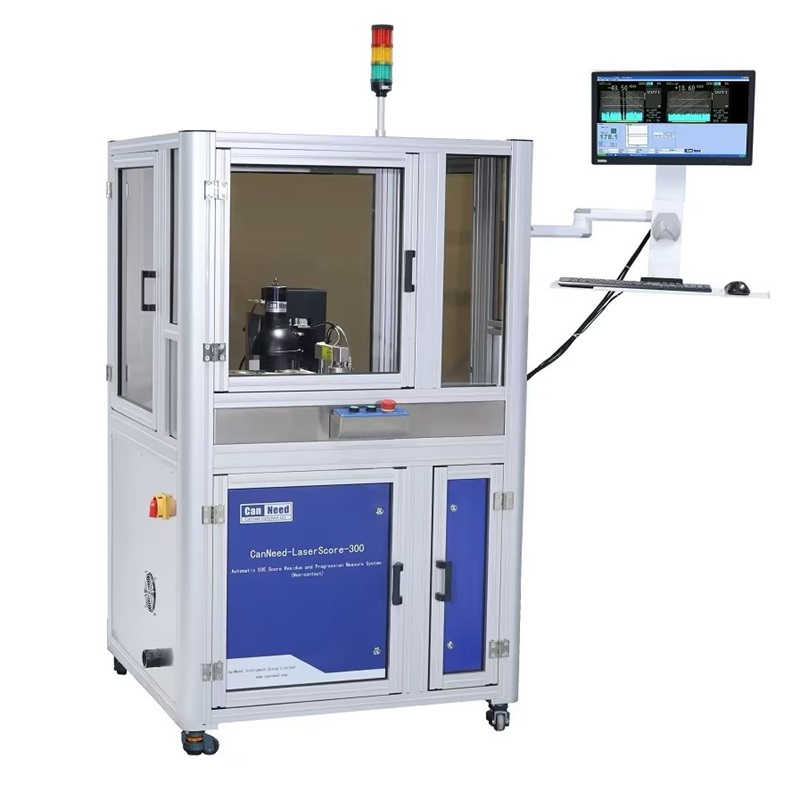

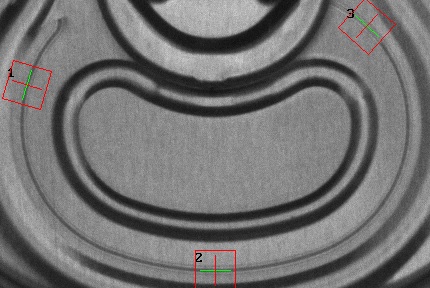

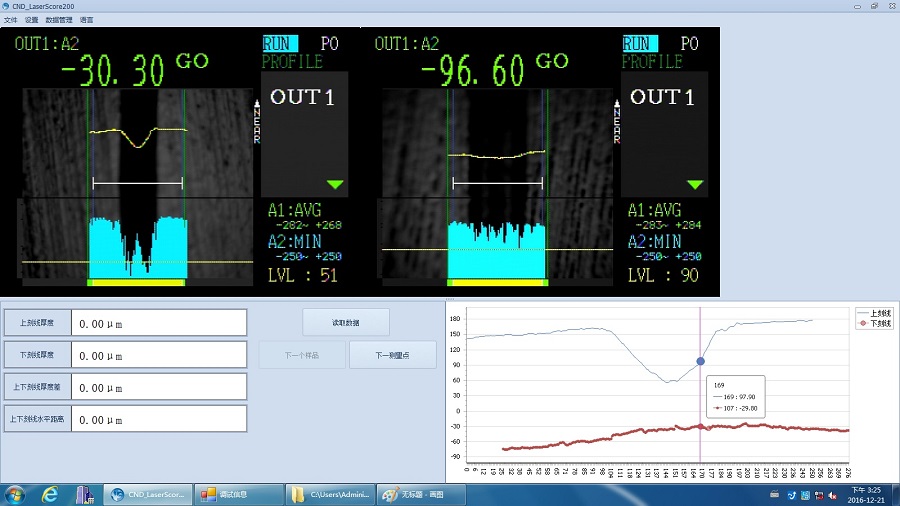

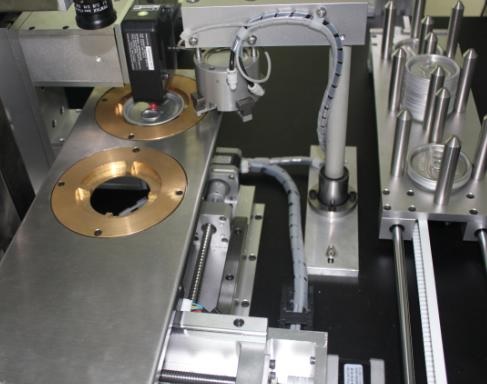

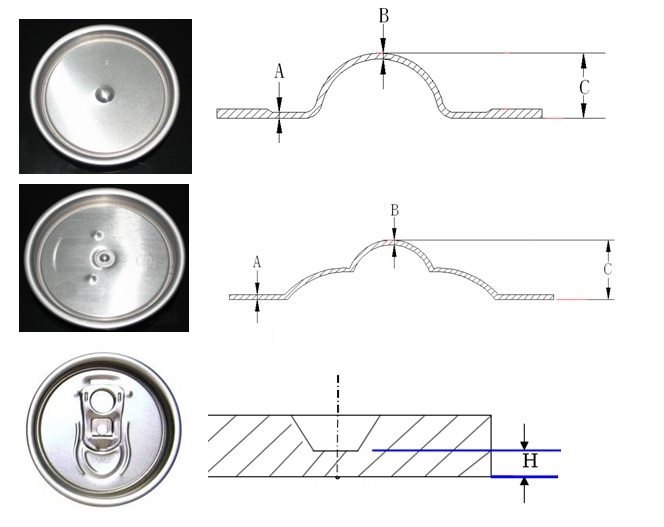

Based on laser technology and automatic visual positioning technology, the CanNeed “LaserScore-300 Automatic EOE Score Residue and Progression Measure System” is used to inspect EOE score residue and rivet convex progression automatically. LaserScore-300 has 2 work positions, each position adapts to inspect 202, 206 and 209 EOE.

Put several EOE samples stacked in the position to be measured, when testing, the automatic sampling mechanical arm will send the sample to the inspection clamp, the servo system coordinate with the automatic visual positioning system, positioning the measuring point accurately, measuring the different points on EOE by turns, the automatic sampling mechanical arm will send the sample from the clamp back to the stacked position after inspection completely each time.

The application of LaserScore-300 realizes automatic measuring batch samples, save time, labor and material greatly.

粤公网安备44120302000118号

粤公网安备44120302000118号