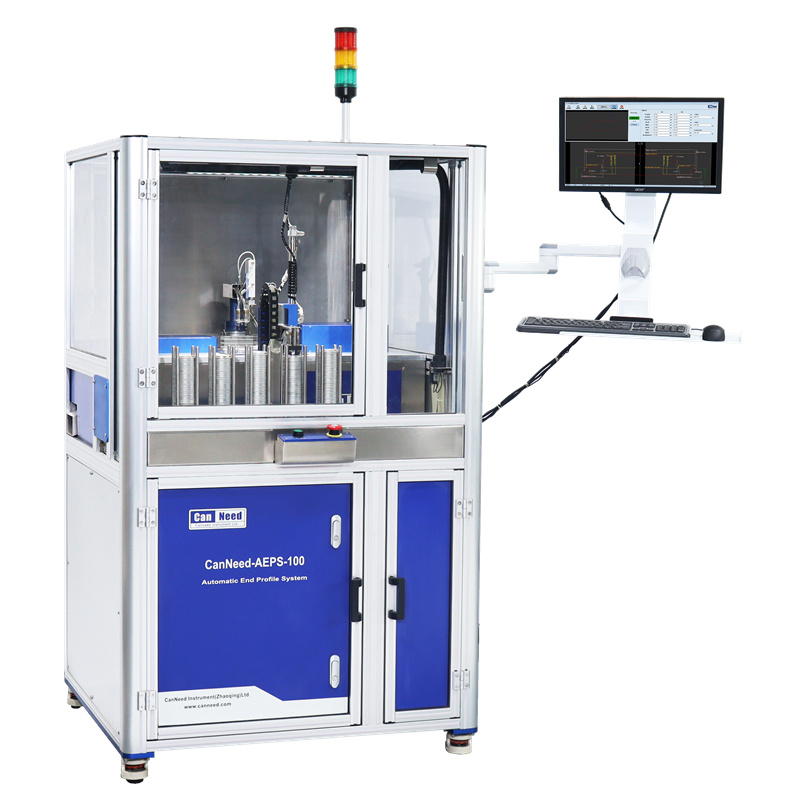

CanNeed-AEPS-100 Automatic End Profile System is used to measure the end dimensions. It is with excellent performance by adopting precise optics measuring technology, measuring the end dimensions precisely.

The inaccuracy of end dimensions usually cause to such double seam defects as fault sealing, bearing cover and false sealing and so on. It is hard to measure the profile dimensions of ends without CanNeed-AEPS-100.

CanNeed-AEPS-100 takes the place of destruction measuring methods. The destruction measuring methods are not only inaccurate and time-consuming, but also get different results because of different operators.

Adopting precise optics measuring technology, CanNeed-AEPS-100 can measure all important parameters of ends.

1) Define the end curl parameters!

2) Quick measurement!

3) High accuracy!

4) Non-contact and non-destructive measurement!

5) Non-destructive end curl width measurement!

6) Able to measure some parameters which were hard to gain before, e.g., end curl width and end curl radius.

7) Provide report

粤公网安备44120302000118号

粤公网安备44120302000118号