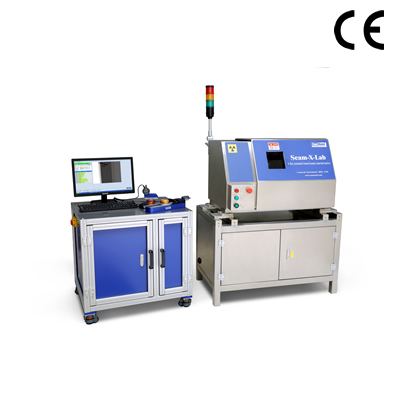

Purpose:

Seam-X®-Lab Automatic Seam Scanner adopts non-destructive measure method to measure the seam dimension, tightness (aluminum and tin composite can excluded), and the actual seam formation.

Measure Items: Seam Length, Body Hook, End Hook, Overlap, %Overlap, Seam Gap, %Body Hook Butting, %End Hook Butting, %Tightness, and the actual seam formation.

It is able to identify if the double seam is fake or not base on the actual seam formation

It’s applicable to measure cans of various materials. Combination of can body and the end can be

following: (1) Aluminum & Aluminum; (2) Tin & Tin; (3) Tin & Aluminum.

Seam-X®-Lab can work together with the seam thickness gauge and countersink gauge, to make up a

complete measure system for the double seam.

1) Waste no sample, save cost and environmental protection.

2) Auto measure, quick and efficient, simple operation

3) More accurate, avoid manual measurement error

4) Outstanding repeatability and reproducibility (R&R)

5) 360° fully scan measurement of tightness

6) Invention patents granted

7) Comply with safety criteria of X-ray radiation protection, certified by the third party (0.08mSV/year).

8) Safe operation to avoid injury result from cutting method

9) Easy calibration with provided calibration piece

10) Suitable for cans of various sizes and specification

11) Software automatically open and close the protection door

12) Automatic judge passed or failed

13) Welding identifying function for 3-piece can (Optional)

14) Measure data can be stored in SPC automatically

Sample spec.: Combination of can body and the end can be following:

(1)Aluminum & Aluminum; (2)Tin & Tin; (3)Tin & Aluminum

Sample size: Can Diameter: 113 (48 mm)-603 (153 mm);

Can Height: 50- 300mm

Measure items:

1.Seam Dimension: Seam Length, Body Hook, End Hook, Overlap, %Overlap, Seam Gap, %Body Hook Butting, %End Hook Butting

2.Tightness (*excluding aluminum and tin composite can)

3.Actual Seam Formation (*excluding aluminum and tin composite can)

Unit: Dimension: inch, mm;

Tightness: %

Language: English & Chinese

Accuracy: Seam Dimension: +/- 0.01 mm

Tightness: +/- 5%

Resolution: Seam Dimension: 0.001 mm

Tightness: 1%

Output: Ethernet, ASCII, TXT, SQL, DBI

Power: 100-240VAC, 50/60 Hz

Dimension: L1500×W1000×H1900mm

Weight: Approx. 650kg

粤公网安备44120302000118号

粤公网安备44120302000118号