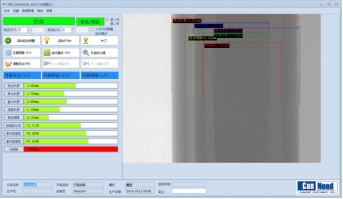

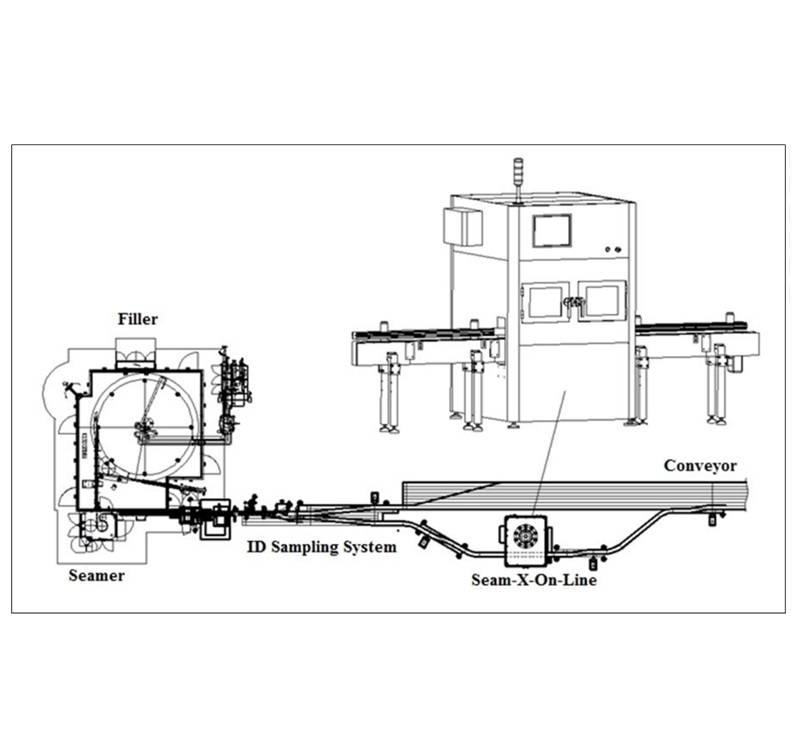

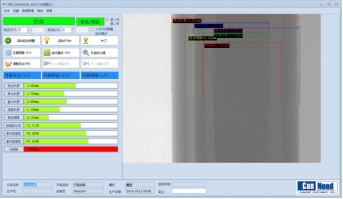

Seam-X®-On-Line Automatic Seam Scanner adopts non-destructive measure method to measure the seam dimension. It is applicable to be installed by pass the production line, taking the samples and measuring them.

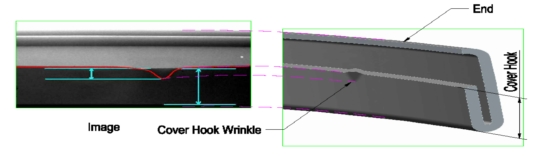

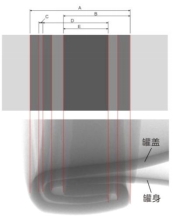

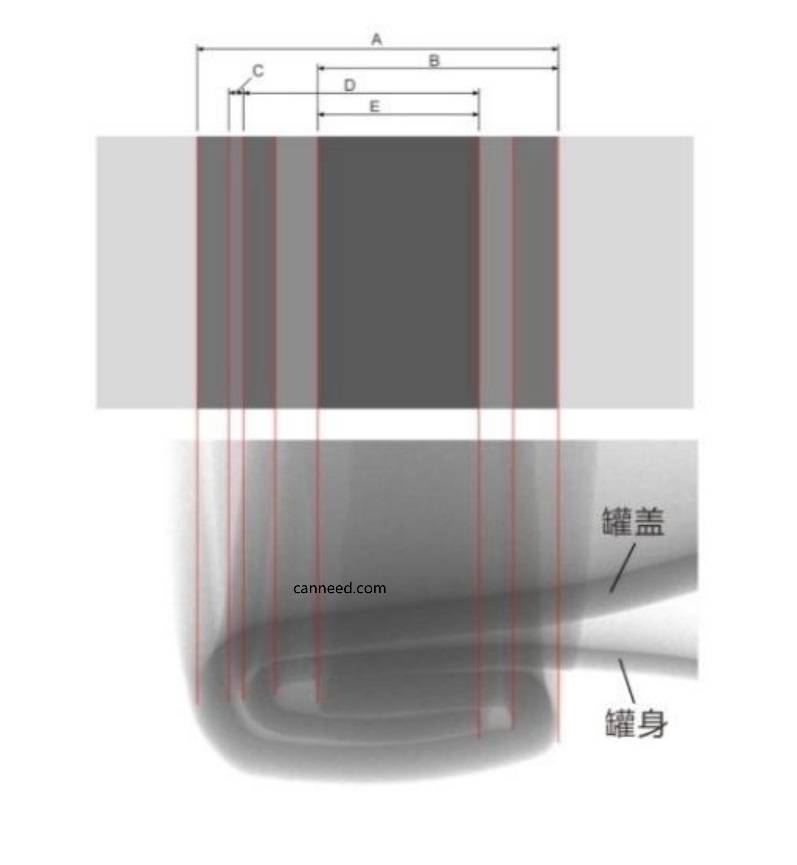

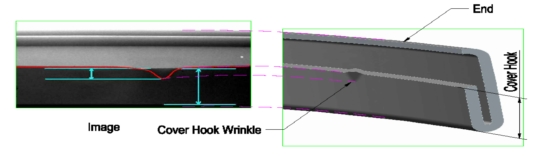

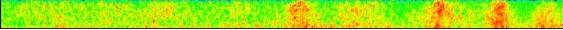

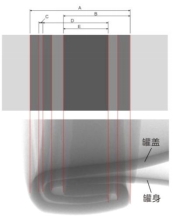

Measure Items: Seam Length, Body Hook, End Hook, Overlap, %Overlap, Seam Gap, %Body Hook Butting, and %End Hook Butting.

It’s applicable to measure cans of various materials. Combination of can body and the end can be following: (1) Aluminum & Aluminum; (2) Tin & Tin.

Seam-X®-On-Line can work together with the seam thickness gauge and countersink gauge, to make up a complete measure system for the double seam.

If configured with identification sampling system, it can make the result of every can correspond to the related seamer head.

粤公网安备44120302000118号

粤公网安备44120302000118号