CanNeed-FMS-2000 Automatic Front End Measure System is used to measure Bottom Depth, Can Height & Topwall and Midwall Thickness of 2-pc can. It’s designed based on practical experience and applied for back end inspection. It can be used to test different sizes of cans, and there is no need to replace clamps.

Adopt standard calibration gauge, imported micrometer, and touch screen PLC control & display.

Testing Process:

-The sample will rotate automatically when measurement starts.

-The 3 pneumatic controlled sensors will measure the sample automatically. -50 sample points can be set at most in 1 circle.

-Auto measure bottom depth, can height, wall thickness of upper and middle end.

-Measure results can be transferred automatically by a RS232 cable.

• Auto measure, save time, and avoid human error.

• Can measure samples of different diameters and heights. Fast replacement of cans ,and no need to change clamps.

• transition points of wall thickness

• Vertical measurement is adopted to avoid the error of can height and depth of Bottom arch caused by reverse tank measurement.

• Adopt high precision and the most advanced sensors, with excellent accuracy and repeatability (R&R).

• Efficient, fast and accurate measurement to improve detection efficiency.

• Strong, durable, easy to operate and maintain.

• hard alloy measuring head, durable

• Adopt world class components

• Auto save data and testing result output to computer or SPC system through RS232

• Protective door with safety lock to prevent hand injuries during testing process or daily maintenance

|

|

|

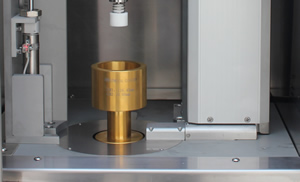

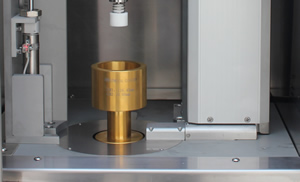

Testing different sizes of samples, auto clamping, and no need to replace clamps

|

|

|

|

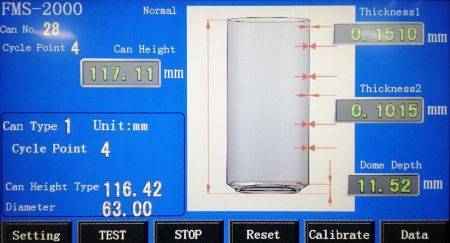

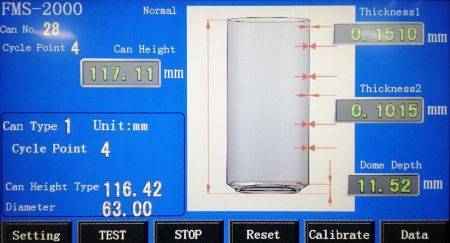

Operating interface

|

Fast calibration

|

粤公网安备44120302000118号

粤公网安备44120302000118号