CanNeed-ATT-110 Automatic Torque Tester, is a new instrument developed by CanNeed, to test the torque value of caps for bottled packaging products, nozzle packaging products, hose packaging products. Applicable for National Standard, Industrial Standard: GB/T 17876, ASTM D2063, ASTM D3198, ASTM D3474, BB/T 0025, BB/T 0034.

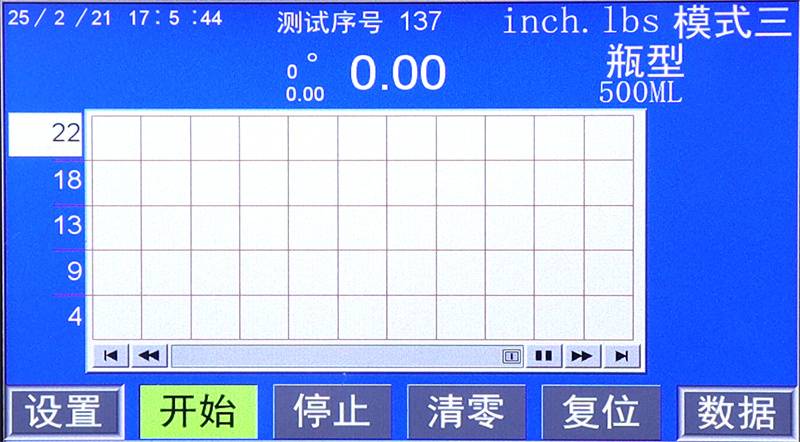

The instrument is to measure by contact method. Just need to place the bottle sample on testing platform and press start button, the bottle positioning clamp will clamp the bottle. Then the cap rotary fixture will drop vertically to clamp the cap, twist the cap and measure. The display screen records the display value. After measurement finished, the bottle positioning clamp will be released and all action reset.

1. To adopt the integrated structure design of wire rod module and servo motor system. Automatic measurement, more accurate process and measurement.

2. The measurement range is wide and applicable for different sizes of samples.

3. Simplified mechanical structure, desktop type. Adopts domestic and abroad famous brand components. E.g. AirTac, SMC, Leadshine.

粤公网安备44120302000118号

粤公网安备44120302000118号