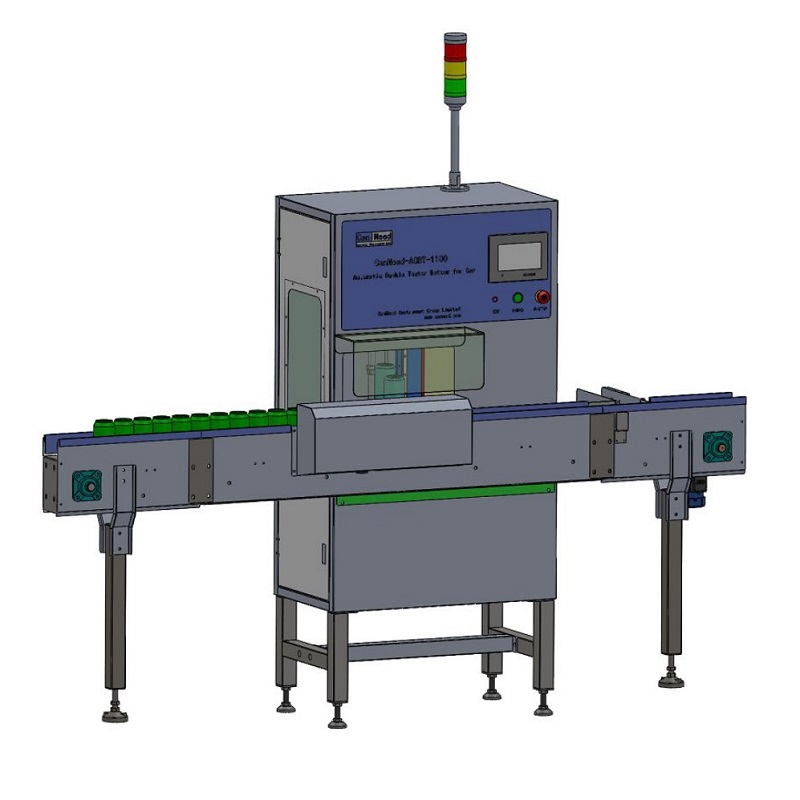

CanNeed-ACBT-1100 is a full automatic buckle tester bottom for cans with unattended operation. It used to test the maximum pressure before can bottom starts to deform, and with dome growth function. CanNeed-ACBT-1100 is a standard instrument for can-making industry to achieve continuous and efficient automatic detection.

CanNeed-ACBT-1100 is equipped with auto sampling device which conveys the can to the testing area automatically. Swinging mechanical hand pushes the can to the testing station and it will measure and sort unqualified products automatically. It is also equipped with unqualified products samples retention channel, to facilitate users to analyze unqualified products.

There is no need to change the clamps, applicable for empty necked-in cans and straight wall cans at the same time. It just need to change the clamps simply, applicable to test the cans with different diameters at the same time. Testing results can be saved in database and automatically transferred to SPC system.

1) Auto measurement: the buckling pressure of the can bottom, with dome growth function.

2) Auto measurement in all process saving time and cost of HR, avoiding personal errors.

3) Multi-channel sampling device, can measure various cans at one time.

4) No need to change the clamps, applicable for empty necked-in cans and straight wall cans at the same time.

5) Single station, just change the clamps simply to test different diameters of cans at the same time.

6) Three measuring modes: Buckle Mode, Dome Growth Mode, Length Mode.

7) Sort unqualified products automatically, with unqualified products samples retention channel, to facilitate users to analyze unqualified products.

8) Adopt world-class advanced and precise sensor with outstanding accuracy and repeatability

9) The users can select different measuring units (Psi, bar, Kpa) through software.

10) Real-time display the measuring values and the curve.

11) Effective, quick and accurate measurement, improving inspection efficiency.

12) Secure, durable, easy operation and maintenance.

13) Assemble with world-class components.

14) Assemble with HD camera for convenient after sale service via remote connection.

15) Adopt independent electrical and mechanical warehouse design to facilitate inspection and maintenance.

16) Testing results can be sent to SPC.

17) Equipped with powerful database management software, convenient for data query and statistics.

18) Can review individual sample data after test multiple samples. Can calculate the max. and min. measuring value and average automatically.

19) Data can be saved to Excel form.

20) User defined report format, suitable for the enterprises’ styles and formats.

粤公网安备44120302000118号

粤公网安备44120302000118号