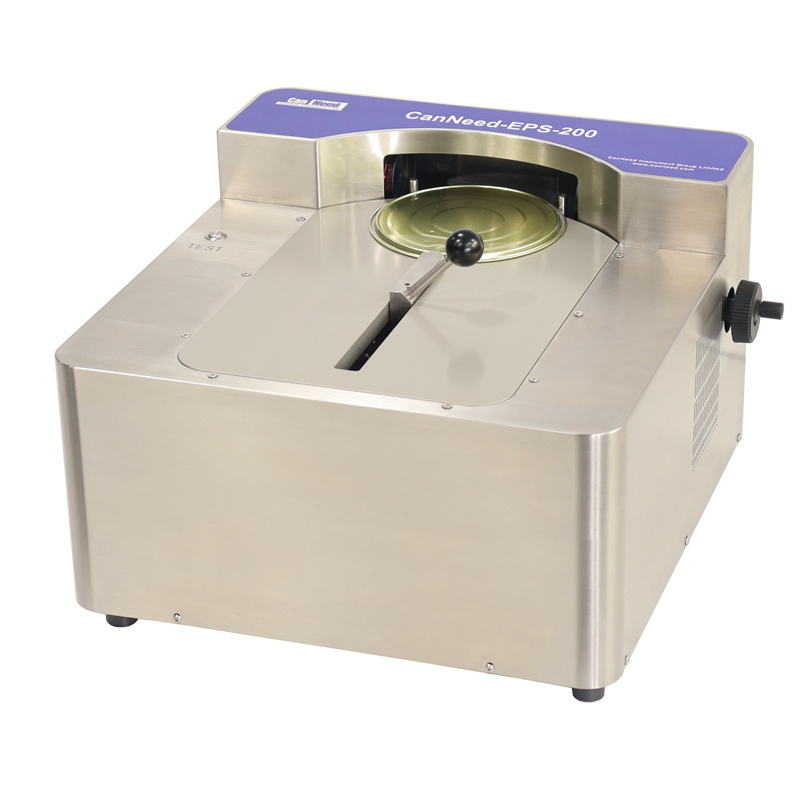

CanNeed-EPS-200 End Profile System is used to measure the end dimensions. It is with excellent performance by adopting precise optics measuring technology, measuring the end dimensions precisely.

CanNeed-EPS-100 adopts precise optics measuring technology, takes the place of destruction measuring methods. The destruction measuring methods are not only inaccurate and time-consuming, but also get different results because of different operators. The inaccuracy of end dimensions usually cause to such double seam defects as fault sealing, bearing cover and false sealing and so on. With CanNeed-EPS-200 End Profile System, it can easily measure the entire profile parameters of ends.

1) Install the clamp by manual, will measure 12 parameters of end automatically after press one button: End outer diameter, End internal diameter, Chuck adapting diameter, End curl width, End curl height, Outer end curl radius, End countersink, End flange, Total height, End Angle, End thickness, Countersink bottom radius.

2) Industry-pioneered end and pressure head matching measurement module is optional. Install the clamp by manual and scan pressing head of can seamer, the profile parameters such as height, diameter, segment radian and angle of pressing head can be calculated automatically after one key point selection. The software can quickly obtain the image of the fitted pressure head and end, and obtain the matching parameters such as matching diameter, angle and bottom gap.

粤公网安备44120302000118号

粤公网安备44120302000118号