Purpose:

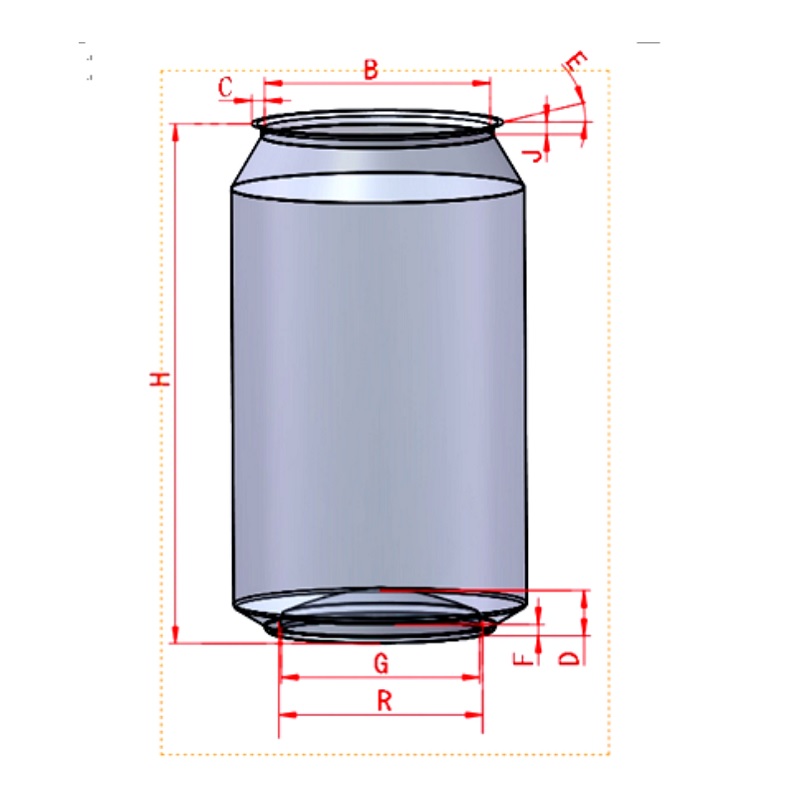

The CanNeed-AOBMS-2000 is an automatic can Measure System for Back End with unattended operation. It’s adopted non-contact laser way to automatically measure flange width (C), can height(H), inner can mouth diameter (B), bottom arch depth (D), flanging Angle (E), roll seal clearance (J), reforming diameter (R), reforming height (F), minimum diameter of can bottom (G) of 2-pc cans. The machine adopted fully automatic inspecting technology, more efficient and more effectively reducing the human errors. It is the standard for evaluating can quality in can-making industry.

Testing process:

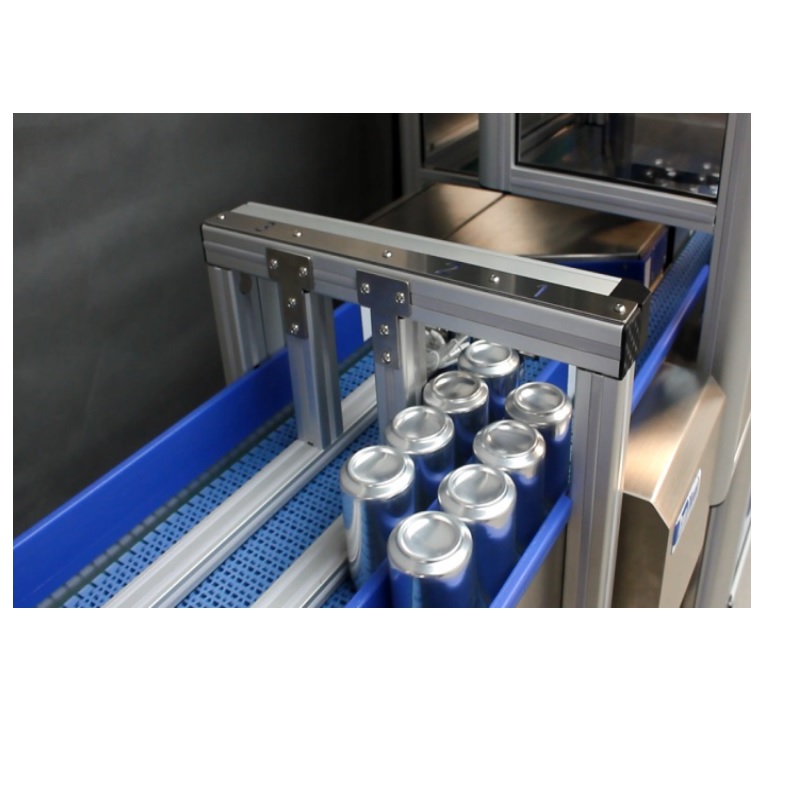

1. Automatic sampling device, the sample cans will be automatically transmitted to the waiting area to be inspected;

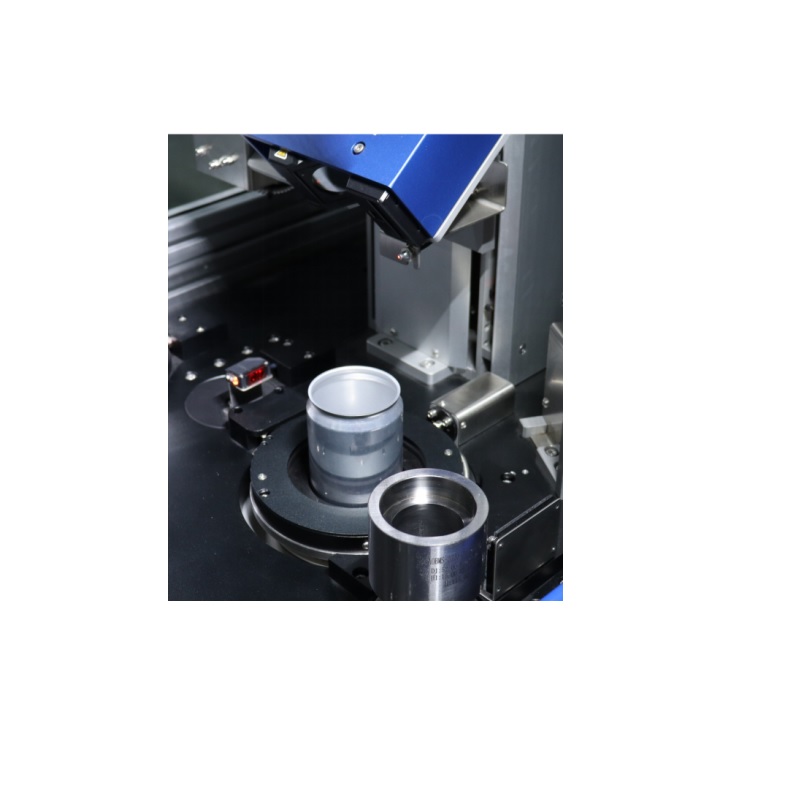

2. The rotary robot arm will transfer the sample cans to the testing station, then the centering mechanism will quickly locate the sample cans;

3. The rotating mechanism drives the sample can to realize 360 degree multi-point sampling according to the user-defined angles. The two laser heads at the top and bottom automatically scan and detect the sample cans, and automatically measure flange width, can height, inner can mouth diameter, bottom arch depth, flanging angle, roll seal clearance, reforming diameter, reforming height and minimum diameter of can bottom;

4. Tested data can be auto-stored by software and transferred to SPC systems automatically;

5. The rotary robot arm can grab the calibration column according to the preset time and frequency to realize multi-point calibration at different angles.

1.Non-contact measurement by Laser.

2.Dual laser heads automatically simultaneous multi-point measurement: flange width (C), can height (H), inner can mouth diameter (B), bottom arch depth (D), flanging Angle (E), roll seal clearance (J), reforming diameter (R), reforming height (F), minimum diameter of can bottom (G).

3.Two world class Laser heads scan the can profile, measuring speed up to 15 seconds/can.

4.Multi-channel sampling device, can measure various cans at one time.

5.Apply to sample cans with different diameters and heights. Quick switching can and no changing parts required for different can sizes.

6.Can customize the location and number of testing points.

7.Automatic calibration, can customize the calibration time and the number of calibration points.

8.Auto measurement in all process saving time and cost of HR, avoiding personal error.

9.Secure, durable, easy operation and maintenance.

10.Assemble with HD camera for convenient after sale service via remote connection.

11.Test result can be sent to SPC system.

12.Database management software for easy data query and statistics.

13.Can review single measure result after test for various cans, Auto calculate the average, maximum and minimum.

14.Data can be stored to Excel form.

15.Various statistics reports. User-defined report format, suitable for style and format of enterprises.

粤公网安备44120302000118号

粤公网安备44120302000118号