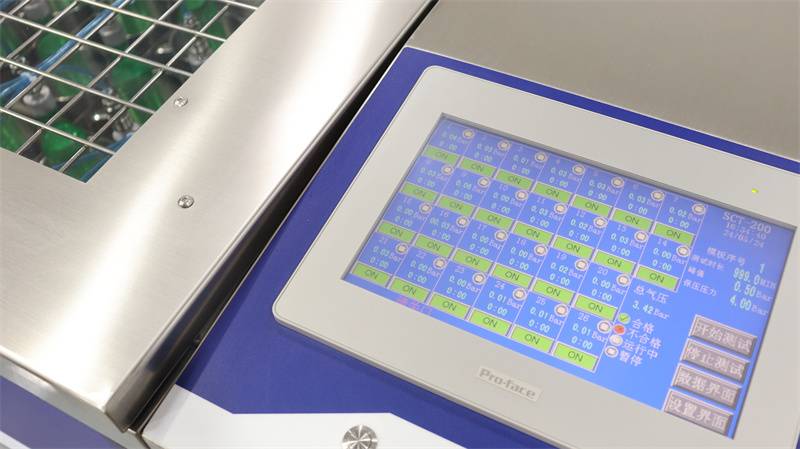

CanNeed-SCT-210 Stress Cracking Tester is a special instrument for testing the stress crack resistance of blow-molded PET carbonate bottles.The effect of lye on PET bottom was tested after the production line was cleaned.The 26 stations, each station has a corresponding pressure test, in the set time to observe the PET bottle bottom rupture.

Measurement method: Constant pressure test, simulate the pressure inside the gas-containing bottle, use compressed air to make the pressure inside the PET stabilize at the set pressure, the bottom of the bottle is immersed in lye, observe the damaging effect of lye on the bottom of the bottle.

Measurement method: Measure the value of air pressure, determine whether it is ruptured through the fall of air pressure, remove the sample after the test to observe the damage degree of the sample.

Main features:

l Equipped with high-precision sensor, each station sensor is independent, can choose any station to test;

l Independent lye test chamber, the solution leaking out of any one bottle after rupture will not affect the other stations. Traditional test is communal lye, one of the leakage will affect the concentration of the test solution, resulting in inaccurate test;

l Each station has an independent intake valve, any sample leakage can quickly close the corresponding intake valve, without affecting other stations;

l Type-C quick connector for installation and replacement. Avoid rotating the air tube many times when tightening the cap, which is easy to leak;

l With marked connector, can quickly find abnormal test samples;

l Accurate measurement, automatic background backup of measurement results;

l Double intake pressure regulator to ensure stable secondary pressure, with clean and dry air.

粤公网安备44120302000118号

粤公网安备44120302000118号