1) Full automatic line positioning (Auto measure), measurement finished within 1 second!

2) Equipped with Golden Lens® video capture device which interference-free of external light source and ensured the high image definition

3) SPC compatible, use a data adapter to collect the data from Mitutoyo Digital Indicator (Actual Seam Thickness; Actual countersink)

4) Connect the Seam Sight to the USB of PC for electric power. Extra power supply is not needed.

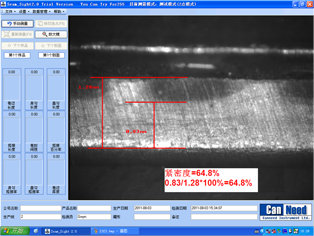

5) Tightness can be measured

6) There are 5 calculation formulae of Overlap Rate for clients to choose

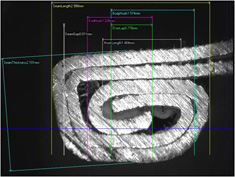

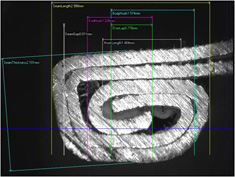

7) Resolution: 0.001mm Accuracy: 0.005 mm Magnification factor: 60 X Line positioning magnification factor: 180 X

8) Magnifier option enable users to magnify the testing image for a more accurate line positioning

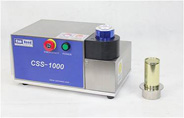

9) The Anti-noise Seam Saw can be chosen, help protect your hearing

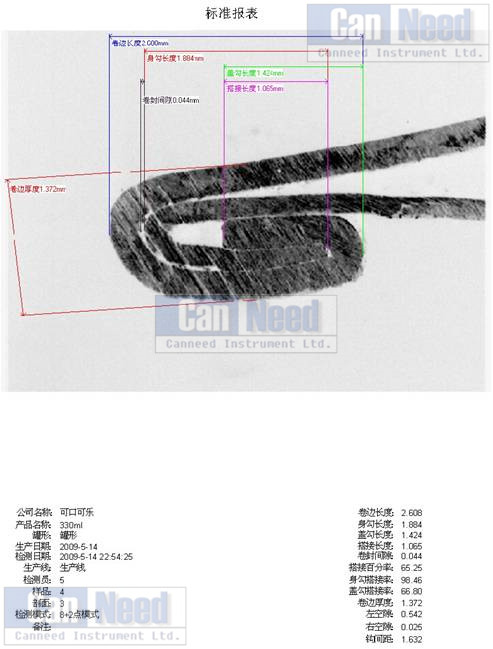

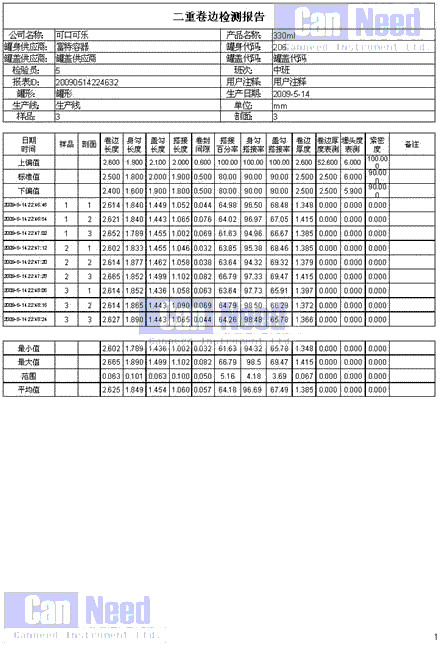

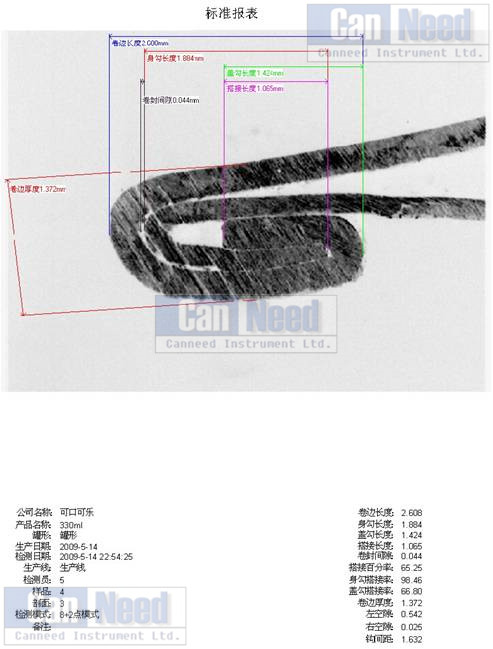

10) Report format can be customized, flexible for different report styles of different companies

11) 12 Measuring Items: Tightness, Seam Length, Body Hook Length, End Hook Length, Overlap, Seam gap, Overlap rate, Body Hook lapping rate, End Hook lapping rate, On-screen Seam Thickness; Actual Seam Thickness; Actual countersink;

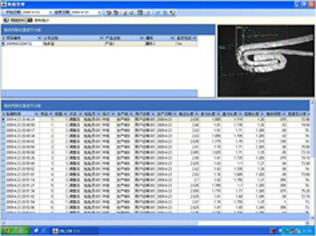

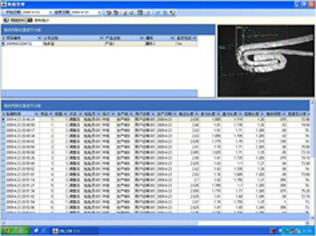

12) Software adopted data base management system, measurement results and images saved in the data base

13) Users can review or re-measure the saved projects at any time

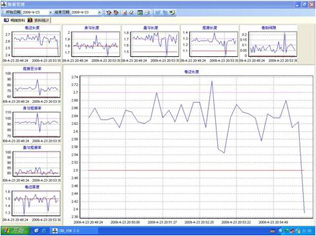

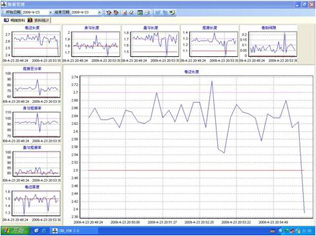

14) Graph chart statistic function, automatically analyze and compare the measurement results

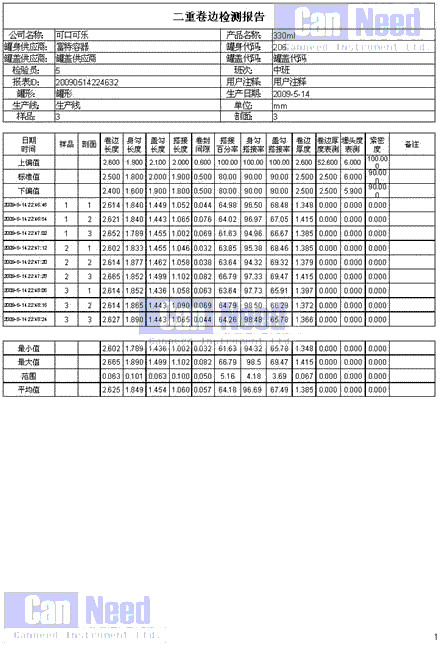

15) Data can be exported as an Excel file

16) Predefine various qualification standards, auto judge and warn whether the results are qualified in every measure

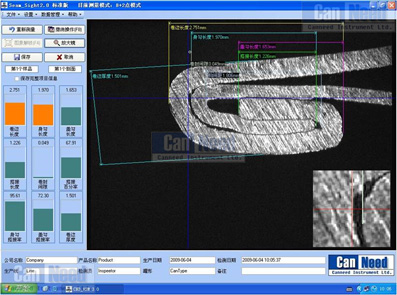

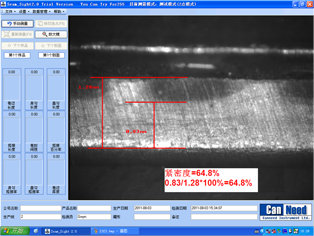

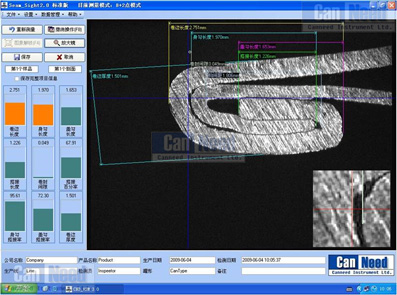

17) Measurement results and label lines mark directly on the image, results will also display in corresponding field on the screen

18) Seam image can be printed, stored, no need to retain the sample cans.

19) Provide with calibration piece, calibrate at any time

20) Use the monochromatic source, make it much more durable

CanNeed SeamSight®- D

Full Automatic Seam Monitor

Most hot-selling around the world for 4 consecutive years, leading technology, auto measuring and data collection, interference-free of external light source

CanNeed and Seam Sight are the registered trademarks of CanNeed Instrument Ltd.

The CanNeed Seam Sight® professional seam measuring software will do the line positioning automatically and the measurement to be finished within 1 second! The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

The CanNeed Seam Sight® Full Automatic Seam Monitor has adopted the advanced optical system and Golden Lens® video capture device, which interference-free of external light source and ensured the high image definition and the measurement accuracy. The Seam Sight® system is equipped with the new seam measuring software Seam Sight®.

SeamSight®-D Full Automatic Seam System

The CanNeed Seam Sight ® system can automatically collect the data from STG200-d Seam Thickness Gauge and CSG-d Countersink Gauge. The actual seam thickness and countersink can be generated reports together with other data. To optimize the measurement process.

Measurement Process

Before cutting the sample can, use STG-200-d Seam Thickness Gauge to measure the seam thickness rate; meanwhile, use CSG-d Countersink Gauge to measure the countersink rate; then the Seam Sight -A will collect the both data automatically.

After that, the sample can should be cut with CSS-1000 Anti-noise Seam Saw or CSS-2000 Seam Saw and placed at the camera position of the monitor. Then, the seaming images will be displayed on the screen. The auto measurement will be finished within 1 second if you press the “Confirmation” button. All images and measurement data will be saved in the system data base.

Seam Sight® system collects the data of STG -200-d Seam Thickness Gauge (digital) and CSG-d Countersink Gauge automatically. And transfer the data to computer by a cable. Generate reports with the actual seam thickness, actual countersink and other datas. The measurement process is optimized.

As the seam thickness measured by Seam Monitor is not accurate after cutting, the STG -200-d Seam Thickness Gauge (digital) can measure the actual seam thickness.

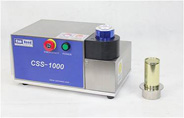

The CSS series Seam Saw

The Anti-noise Seam Saw can be chosen to avoid harsh noise generated by cutting the sample cans, it can help protect your hearing. We have the most professional seaming saws for customers purchasing.

|

CSS-1000 Anti-noise Seam Saw

Applicable for Beverage cans of 50-68mm diameter

|

CSS-100B Anti-noise Seam Saw,

Applicable for Beverage cans of 50-68mm diameter

|

|

CSS-2000 Seam Saw

Applicable for all types of cans of 45-260mm. The

movable cutting platform is installed on the linear guide.

|

CSS-300 Seam Saw

Applicable for all types of cans, especially the large paint drums, square cans.

|

The CanNeed SeamSight®- D Full Automatic Seam Monitor is consisting of:

1. SeamSight-D Automatic Seam Monitor

2. SeamSight 4.0 professional seam measuring software (full automatic line positioning)

3. VSM-CAL Calibration piece 2mm

4. VSM-TH Tightness measurement subassembly

Recommending to purchase the following two items to ensure the seam monitor working:

5. CSS-2000 seam saw or other types of CSS series Seam Saw

6. Laptop

Optional for more efficient:

7. STG-200-d Seam Thickness Gauge (digital)

8. CSG-200S Countersink Gauge(with data output button)

9. TRC-200 Transporter of Computer

10. CMDI Mitutoyo cable (2 pieces)

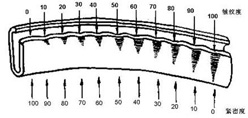

Tightness Measuring Function

It is essential to measure the tightness if you want to determine that the seal of jars or cans is intact. Jars or cans will leak if the tightness is unqualified.

Use the CanNeed STR-100 Seam Stripper to cut down the ends, fix the hook on the Seam Sight-A with the tightness measuring accessories, it can measure the tightness.

The CanNeed Seam Sight®-D Full Automatic Seam Monitor has the Tightness measuring function to avoid visual estimation difficulties as the traditional method.

Features:

l Full automatic line positioning (Auto measure), measurement finished within 1 second!

l Equip with Golden Lens® video capture device which interference-free of external light source and ensured the high image definition

l SPC compatible, use a data adapter to collect the data from Mitutoyo Digital Indicator (Actual Seam Thickness; Actual countersink)

l Just connect to a computer USB interface, no additional power supply

l The tightness can be measured

l 5 optional formulae for seaming overlapped rate calculating

l Resolution: 0.001mm Accuracy: 0.005mm Magnification factor: 60 X Line positioning magnification factor: 180 X

l Magnifier option enable users to magnify the testing image for a more accurate line positioning

l The Anti-noise Seam Saw can be chosen, help protect your hearing

l Report format can be customized, flexible for different report styles of different companies

l 12 Measuring Items: Seam Length, Body Hook Length, End Hook Length, Overlap, Seam Gap, Overlap Rate, Body Hook Lapping Rate, End Hook Lapping Rate, On-screen Seam Thickness, Actual Seam Thickness, Actual countersink and Tightness

l Software adopted data base management system, measurement results and images are saved in the data base, users can facilitate inquires

l Graph chart statistic function, automatically analyze and compare the measurement results

l Users can review or re-measure the saved projects at any time

l Data can be exported as an Excel file

l Predefine various qualification standards, can judge and warn automatically whether the results are qualified in every measure

l Measurement results and label lines can be marked directly on the image, results will be also displayed in corresponding field on the screen

l Seam image can be printed, stored, no need to retain the sample cans

l Provided with calibration piece, calibrate at any time

l Use the monochromatic source, make it much more durable

|

Optional for large measuring platform, it’s able to measure big cans or pails

SeamSight-D

|

It’s able to measure triple seam

(auto measure function is not available for triple seam)

|

Technical data:

*Full automatic line positioning (Auto measure)

*Full automatically collecting the resolution rate of countersink

*Interference-free of external light source

*Be able to measure the tightness

*With SPC data output function

*5 optional formulae for seaming overlapped rate calculating

* Report format can be customized

*Resolution: 0.001mm Accuracy: 0.005mm Magnification factor: 60 X Line positioning magnification factor: 180 X

SeamSight® 3.0 Professional Seam Measuring Software

With the most advanced and complete function: 5 optional formulae for seaming overlapped rate calculating.

Professional seam measuring software (data base management system) with which SPC data statistics and analysis function and SPC data output interface.

|

Measurement results and images saved in the data base management system. Convenience for overview and recheck

|

Various statistics charts analyze the products quality automatically.

|

|

|

User-defined Report, accord with your own requirement

Image Report Datasheet Report

|

1st Generation

|

2nd Generation

|

3rd Generation

|

|

Dial Gauge

|

Digital data displaying

|

Manual Line positioning

|

|

|

VSM II

|

|

|

4th Generation

|

5th Generation

|

|

Auto Line positioning and data collection, interference-free of external light source

|

Non-destructive

|

|

|

Seam-X-Lab Automatic Seam Scanner

Non-destructive

|

New design ideas, from clients’ demand, to meet clients’ needs!!!

Canneed series Seam Sight® have been greatly upgraded:

1. Connect the Seam Sight to the USB of PC for electric power. Extra power supply is not needed.

2. More durable. The warranty period is 2 years against shipment date.

3. More artistic and graceful design.

4. More convenient to position and operate the cans inserted, quick to get the seam images of

high definition.

5. Able to measure the tightness.

6. The software is of better service to the operators with more stable application.

7. There are 5 calculation formulae of Overlap Rate for clients to choose.

8. Canneed series Seam Saw have been greatly improved, ensuring better cutting effects.

……

Please inquire the CanNeed sales for more details about the updated information. Thanks a lot!