|

| |

Product Classification : All Products

|

|

CL-100

|

|

|

|

|

CanNeed-ATCT-1000 Automatic Tensile and Compression Tester

|

|

|

|

|

CanNeed-PTT-C400 Pop & Tear Tester for Cap

|

|

|

|

|

CanNeed-VAT-500

|

|

|

|

|

CanNeed-DSST-300P

|

|

|

|

|

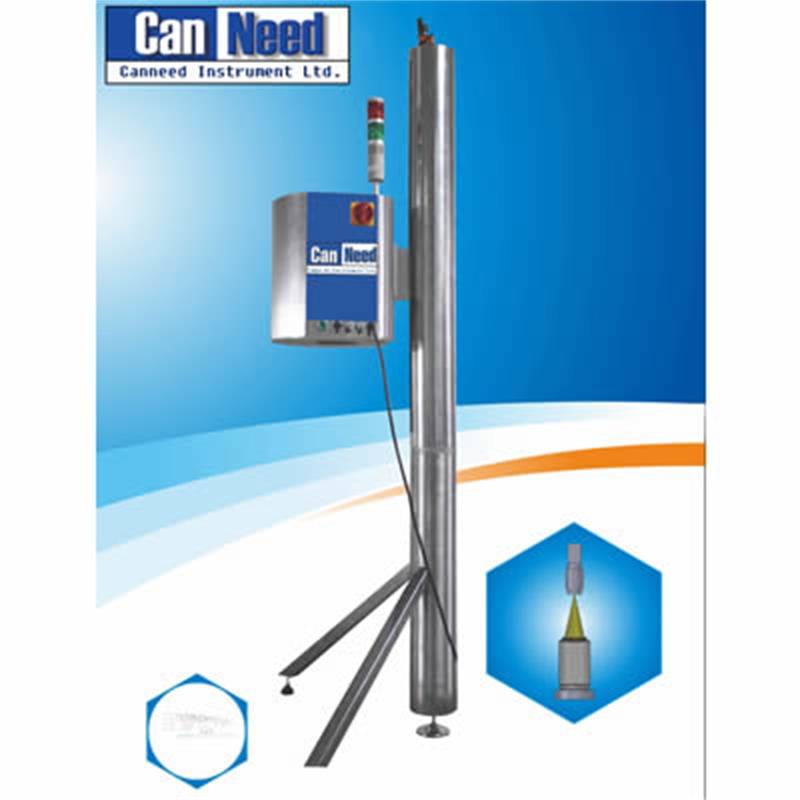

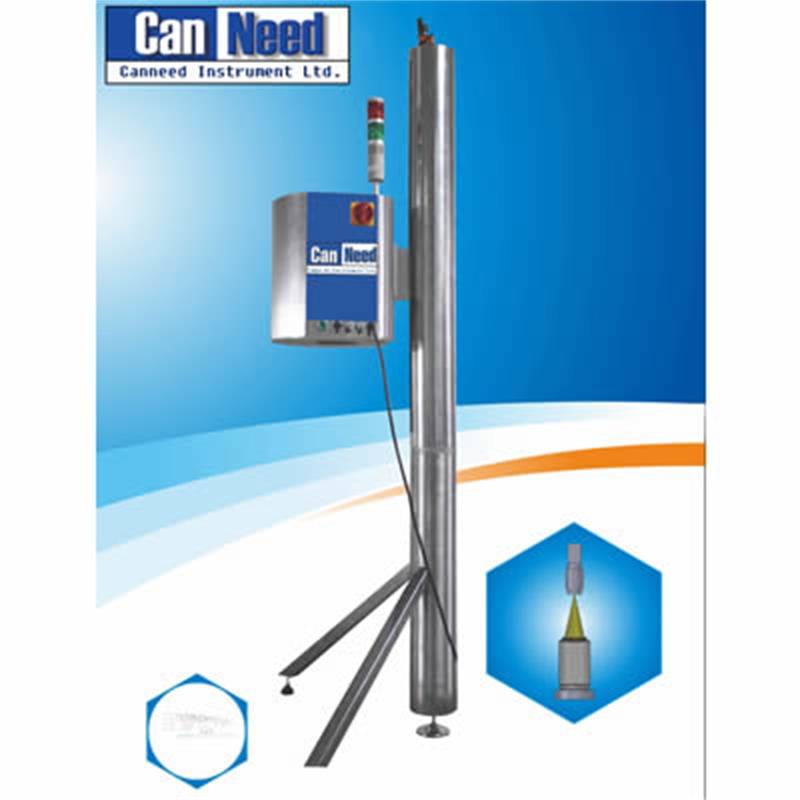

LaserScore-300 Automatic EOE Score Residue and Progression Measure System

|

The CanNeed LaserScore-300 Automatic EOE Score Residue and Progression Measure System (Non-contact)

Inspecting the thickness of End score residue and convex progression automatically

Based on laser technology and automatic visual positioning technology, Canneed’s LaserScore-300 used to inspect EOE score residue and rivet convex progression automatically. LaserScore-300 has 2 work positions, each position adapts to inspect 202, 206 and 209 EOE.

|

|

|

CTG-300 Coating Thickness Gauge

|

|

The Canneed's "CTG-300 Coating Thickness Gauge", equipped with aerodynamic levitation measuring head, provides a computer enhanced method of rapidly assessing lacquer film weight of both internal and external coatings on beverage and food cans, and also tinplate.

The system provides the following benefits to the Can and End manufacturer:Reduced lacquer consumption, Greater product quality, Better operating efficiencies and Lower spoilage.

|

|

|

CanNeed-ASST-Line-1000 Automatic Secure Seal Tester

|

|

CanNeed-ASST-Line-1000 Automatic Secure Seal Tester is used to test the seal integrity of finished products by unattended operation, it effectively controls the sealing properties and prevent gas leakage after packaging. Therefore it is widely used in beverage industry and meets to international inspection standards《GBT 17876-2010 Packaging Container - Plastic Anti-Theft Bottles》.

|

|

|

CanNeed-VSST-100

|

|

|

|

|

CanNeed-SST-300S

|

|

|

|

|

CanNeed-IPT-1000

|

|

|

|

|

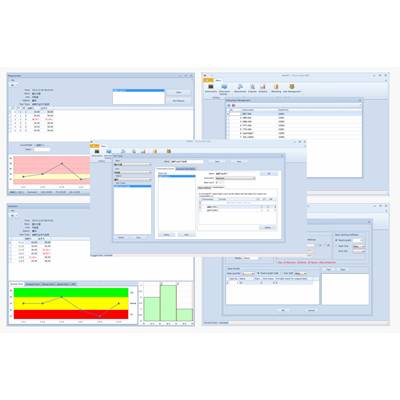

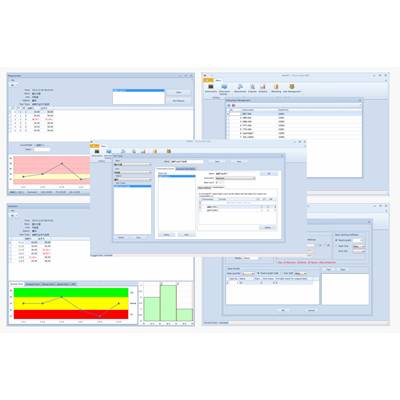

CanNeed-SPC SPC SoftWare

|

|

|

|

|

CanNeed-PEPT-100

|

|

|

|

|

CanNeed-PTT-C400 Pop & Tear Tester for Cap

|

|

|

|

|

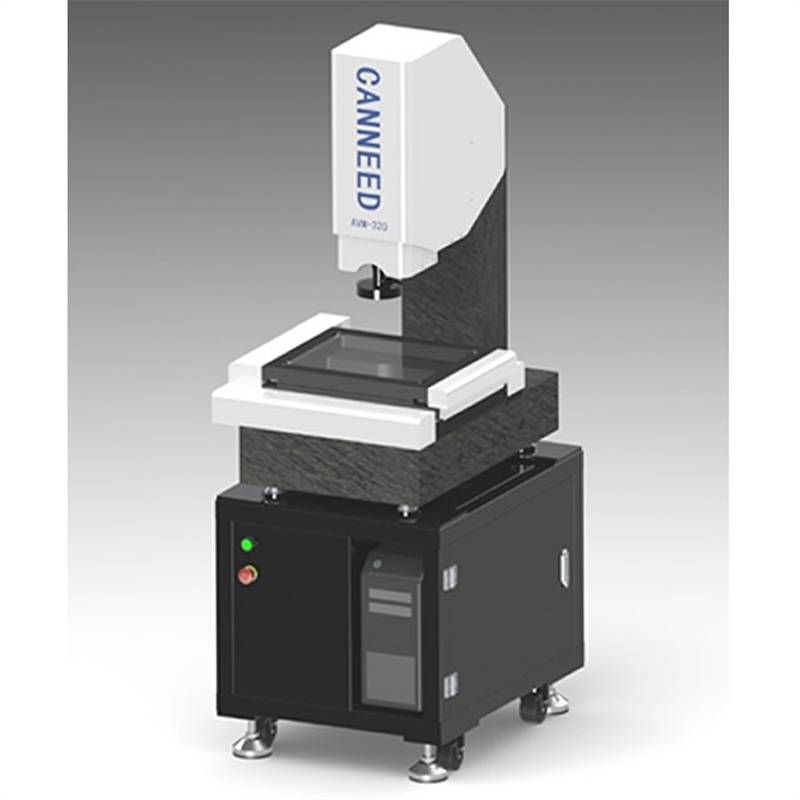

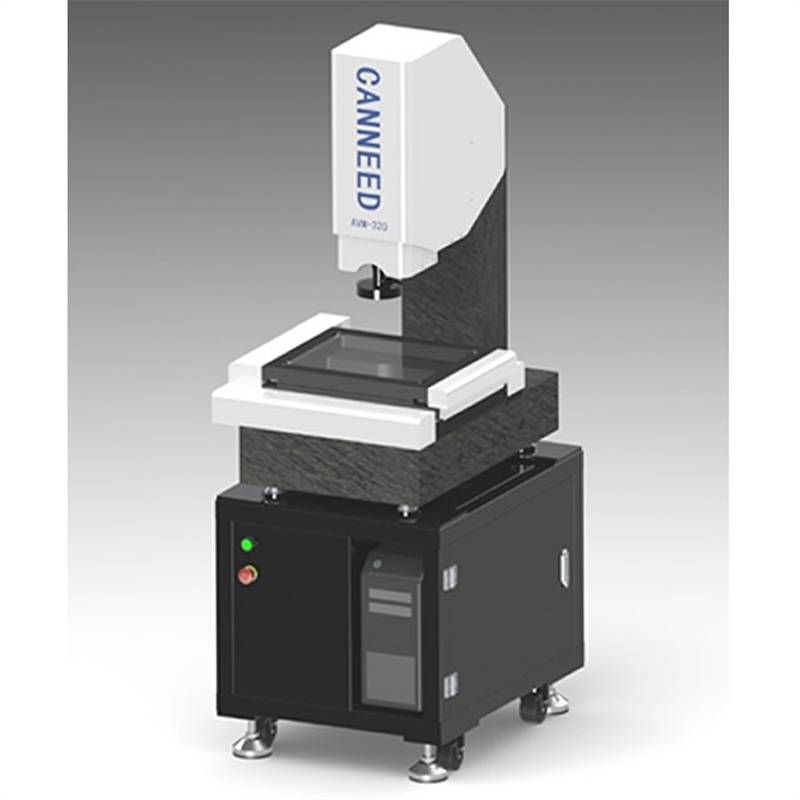

CanNeed-AVM-320

|

|

|

|

|

CND-SST-3 Secure Seal Tester

|

|

The CanNeed “CND-SST-3 Secure Seal Tester” is used to test the seal integrity on the glass or plastic containers and cans. The CND-SST-3 has been designed to address the special needs of sealing cans and bottles that use aluminium roll-on, twist crowns, or plastic caps. The CND-SST-3 operates with compressed air, nitrogen, or carbon dioxide. By detecting gas leakage, rather than liquid, the Secure Seal Tester gives more sensitive and accurate readings.

CND-SST-3 is made from anodized aluminium, stainless steel, and plastic materials. The tester's rugged construction withstands production line abuse, yet is accurate enough for laboratory use.

|

|

|

CSS 2000 Seam Saw

|

The CanNeed CSS-2000 Seam Saw is applicable for all types of cans of 45-260mm. The movable cutting platform is installed on the linear guide.

The CanNeed “CSS-2000 Seam saw” is a special seam circular saw with double cut for double seam inspections. The CSS-2000 was specially designed for 2- and 3-piece cans.The nitrated blades achieve together with the speed of approx. 1.000 r/min. a very plain cut surface. The seam image on Caneed series Automatic Seam Computer (Video Seam Monitors), and automatic seam measuring systems gets thereby very clear and improves measurement speed and reliability.

|

|

|

Seam Sight(TM) Full Automatic Seam Monitor

|

The Seam SightTM Full Automatic Seam Monitor is a compact measuring system for quick and accurate automatic seam measurements and storing of seam images.

The seam is positioned manually in front of the camera and is digitised by the computer.

In less than 1 second the Seam SightTM software offers a measurement. The seam length, body hook, end hook, actual overlap, percentage overlap; seam gap, seam thickness and body hook butting% are measured. At the end of the measurement an evaluated seam appears including dimension lines and measured values. This may be stored in computer or printed out on a laserprinter. The values can be stored in a Excel file and are displayed in on-screen if values are within specs.

|

|

|

SeamSight®-B Full Automatic Seam System

|

|

The CanNeed Seam Sight ® -B system can automatically collect the data from STG-200-d Seam Thickness Gauge and CSG-d Countersink Gauge. The actual seam thickness and countersink can be generated reports together with other data. To optimize the measurement process.

|

|

|

SCG-200 Seamer clearance Gauge

|

|

CanNeed SCG-200 Seamer clearance Gauge, a quick and accurate way to set up seamers.To measure the roll height off the chuck and the lateral distance between the roll and chuck.

|

|

|

CanNeed-CCST-100 Crown Cap Secure Seal Tester

|

|

The “CCST-100 Crown Cap Secure Seal Tester” is used to test the air tightness of crown caps. The tester is made of stainless steel, so that ensure its durability.

|

|

|

DGM-200 Portable Digital Beverage CO2 Calculator (CO2-Gehaltemeter)

|

|

DGM-200 Portable Digital Beverage CO2 Calculator (CO2-Gehaltemeter)

The CanNeed “DGM-200 Portable Digital Beverage CO2 Meter” is common in breweries and soft drink industry to frequently measure the CO2 content during production. It enables a fast and accurate determination of the CO2 content in beer and carbonated drinks, either directly sampled within the production process (from e.g. tanks, pipes) of thereafter (from e.g. kegs).

|

|

|

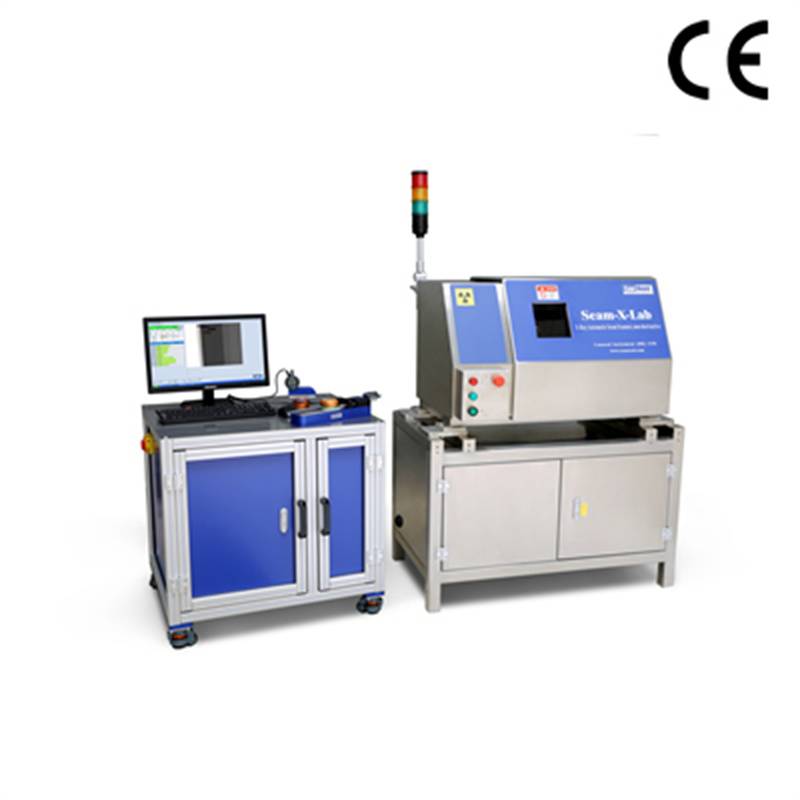

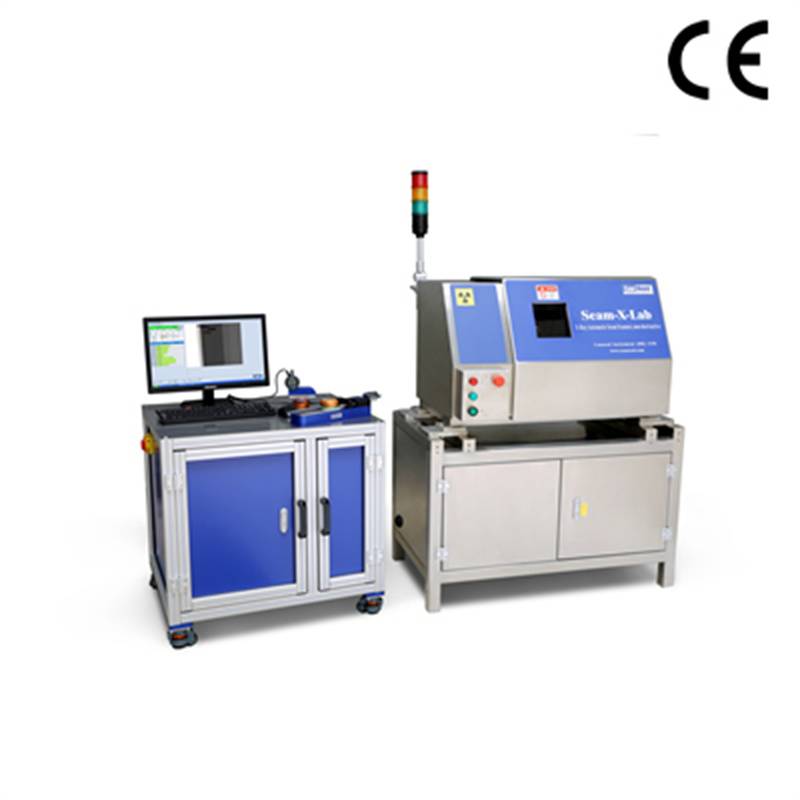

Seam-X®-Lab X-Ray Automatic Seam Scanner(Non-destructive)

|

|

Seam-X®-Lab Automatic Seam Scanner adopts non-destructive measure method to measure the seam dimension, tightness (aluminum and tin composite can excluded), and the actual seam formation.

Measure Items: Seam Length, Body Hook, End Hook, Overlap, %Overlap, Seam Gap, %Body Hook Butting, %End Hook Butting, %Tightness, and the actual seam formation.

It is able to identify if the double seam is fake or not base on the actual seam formation

It’s applicable to measure cans of various materials. Combination of can body and the end can be following: (1) Aluminum & Aluminum; (2) Tin & Tin; (3) Tin & Aluminum.

Seam-X®-Lab can work together with the seam thickness gauge and countersink gauge, to make up a complete measure system for the double seam.

|

|

|

SMM-300 Score Measure Microscope (PC Module)

|

|

The CanNeed "SMM-300 Score Measure Microscope" adopted the microscope technology to measure the score depth and residue of can ends. Equip with the high definition CCD camera system, locating done by displaying the clear groove bottom image of the end score on the screen, the measurement data is accurate, reliable and reproducible. The end sample to be clamped on a two-dimensional platen, which is much easier for locating and measurement. The fine digital indicator which has a resolution of 1µm (0.001mm).

|

|

|

CanNeed-DER-400 Digital Enamel Rater

|

|

CanNeed-DER-400 Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

CanNeed-DER-400 is the industry standard. The new CanNeed Enamel Rater DER-400 instrument test the coverage of the enamel coating inside food and beverage cans, aerosol-cans and also different kinds of ends. It displays an index of the amount of metal exposed by incomplete enamel coverage on a clear, easily read digital LED.

|

|

|

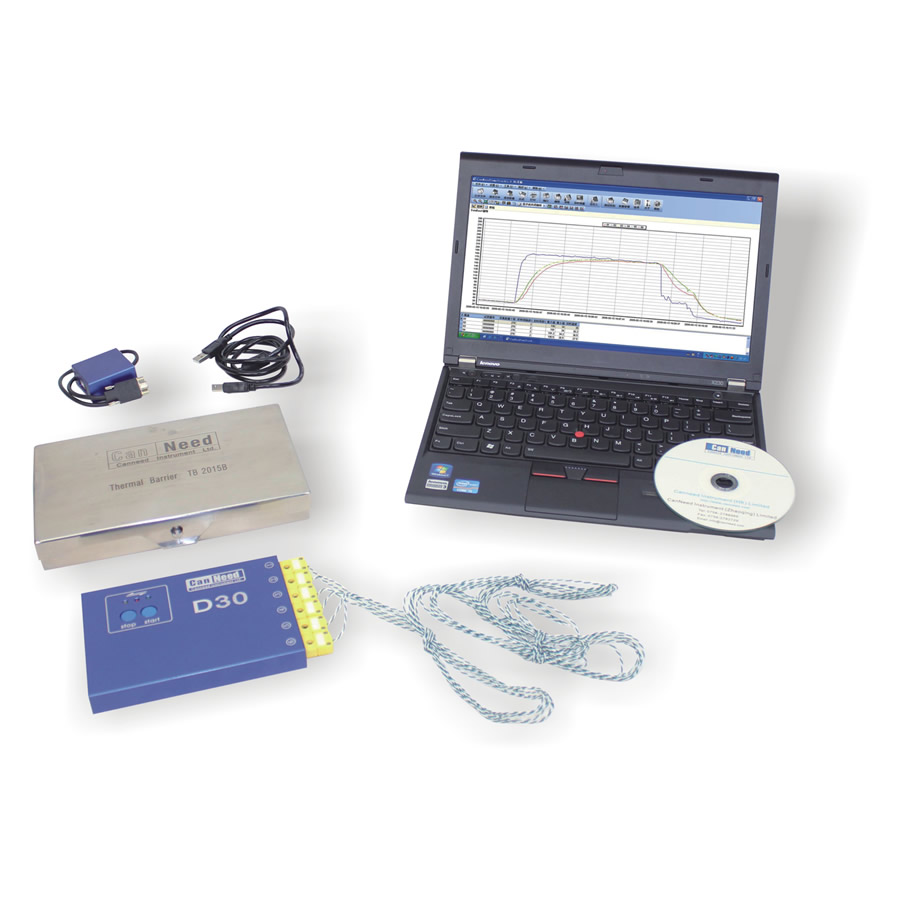

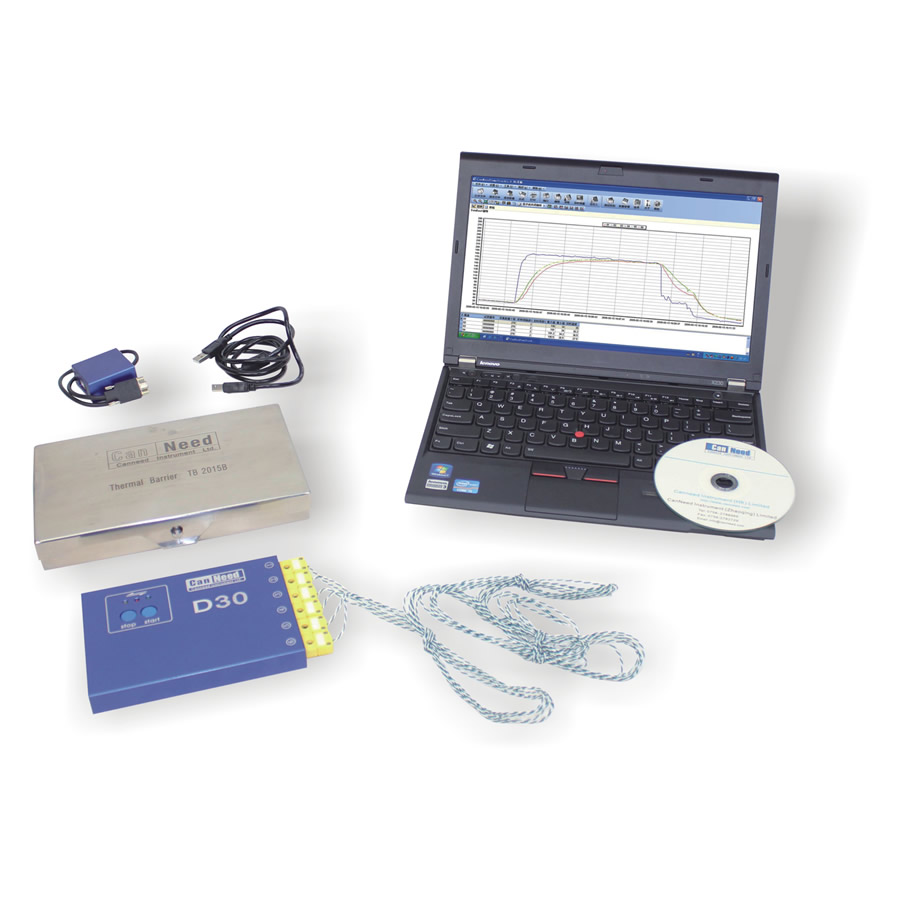

CanNeed-CND-TRK-300 Oven Temperature Tracker

|

|

The “CanNeed-TRK-300 Oven Temperature Tracker” is a professional oven temperature curve inspection system for the coating industry, it is including the data logger, heat insulation case, software (Chinese / English) and thermocouples.

"CanNeed-TRK-300 Oven Temperature Tracker” is use to pass through the oven with the solidifying products, and record down the real temperature during the process. The logger is in the centre of the system. Heat insulation case is for protecting the logger from over heat by the oven. When passing through the oven, the CanNeed-TRK-300 Oven Temperature Tracker will record down the real time temperature of the solidifying products through the 5 thermocouples which were connected to the products, and one thermocouple is for recording the air temperature of the oven. After the recording process was finished, use the CND_TRK Software to analyze the temperature data and generate the detail reports.

|

|

|

CTG-4000 Wet Film and Coating Thickness

|

Application:

1. Test wet film and coating thickness,both save time and improve quality

2. Test both single layer and multilayer coating

3. Adopt non-contact optical technique,suitable for research,quality control and on-line control.

4. Can be used in Solar energe,optical coating,foods package,metal package field.Improve the quality by appearance,adhesion,resistant to corrosion and fricton,as well as scratch.

|

|

|

MBT-300 Hall Effect Thickness Gauge (Magnetic Bottle Thickness Gauge)

|

|

The Canneed “MBT-300 Hall Effect Thickness Gauge (Magnetic Bottle Thickness Gauge” is a refined portable bottle thickness gauge. It can measure the thickness of nonmagnetic material, such as plastic, glass, synthetics, aluminum and titanium, etc. The measurement accuracy is undistorted by the samples’ shapes.

|

|

|

CanNeed-ACH-100 Aerosol Curl Height Gauge

|

|

CaNneed-ACH-100 Aerosol Curl Height Gauge is used for measuring the contact height of the curl 1” aperture of aerosol cans. ACH-100 is the Industry Standard.

|

|

|

EPH-100 End Panel Holder-for Digital Enamel Rater

|

|

EPH-100 End Panel Holder-for Digital Enamel Rater

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|