|

| |

Product Classification : All Products

|

|

SeamSight®-VSM-6A Automatic Seam Monitor

|

|

SeamSight-VSM-6A Automatic Seam Monitor is a compact measuring system for quick and accurate automatically seam measurements, it has adopted the advanced optical system and Golden LensTM video capture device, which ensured the high image definition and the measurement accuracy.

SeamSight-VSM-6A Automatic Seam Monitor is equipped with the professional seam measuring software CanNeed CND_VSM3.0. With the CanNeed SPC data collection system, the data of actual seam thickness, actual countersink, etc., can be transferred to the computer automatically.

|

|

|

SeamSight®-D Full Automatic Seam Monitor

|

|

The SeamSight® system is equipped with the new seam measuring software SeamSight® Professional Software. Which will do the line positioning automatically and the measurement to be finished within 1 second!

Use the CanNeed SPC data collection system, The actual seam thickness, actual countersink, etc., can be transferred to the computer automatically.

The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

|

|

|

SeamSight-A Full Automatic Seam Monitor

|

|

The SeamSight® system is equipped with the new seam measuring software SeamSight® Professional Software. Which will do the line positioning automatically and the measurement to be finished within 1 second!

Use the CanNeed SPC data collection system, The actual seam thickness, actual countersink, etc., can be transferred to the computer automatically.

The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

With CanNeed Automatic Seam Sight® Monitor, press only one key “Auto Measure” to do the line positioning automatically and the measurement to be finished within 1 second! It can measure the seam dimension automatically, efficiently, simply and also avoid operator mistake. Use the CanNeed SPC data collection system (CSG-200 countersink gauge & STG-200D seam thickness gauge), the actual seam thickness, actual countersink, etc., can be transferred to the computer automatically. Such data can generate a report together with other data, improving the process.

|

|

|

CanNeed-SCG-110 Seamer clearance Gauge and Seam Monitor

|

|

CanNeed-SCG-110 Clearance gauge, is a quick and accurate way to set up seamers. To measure the roll height off the chuck and the lateral distance between the roll and chuck.

The Clearance Gauge takes a completely different approach to the problem. To measure the roll height off the chuck and the lateral distance between the roll and chuck.

The Clearance Gauge allows users to do predictive maintenance on their seamers before they go out of specifications. The clearance gauge is able to not only quickly and accurately set up the seamer, but makes sure that all the seamer heads are performing perfectly as near as possible to the nominal value.

Instead of focusing on checking seams after the double seam is already closed, the Clearance Gauge helps optimize the can seaming process by taking out variations between the different seamer heads and optimizing the seamer itself!

Today, covering most seamer models, these seamers show a clear and dramatic performance improvements by using this gauge.

|

|

|

CanNeed-SCG-110 Seamer clearance Gauge and Seam Monitor

|

|

CanNeed-SCG-110 Clearance gauge, is a quick and accurate way to set up seamers. To measure the roll height off the chuck and the lateral distance between the roll and chuck.

The Clearance Gauge takes a completely different approach to the problem. To measure the roll height off the chuck and the lateral distance between the roll and chuck.

The Clearance Gauge allows users to do predictive maintenance on their seamers before they go out of specifications. The clearance gauge is able to not only quickly and accurately set up the seamer, but makes sure that all the seamer heads are performing perfectly as near as possible to the nominal value.

Instead of focusing on checking seams after the double seam is already closed, the Clearance Gauge helps optimize the can seaming process by taking out variations between the different seamer heads and optimizing the seamer itself!

Today, covering most seamer models, these seamers show a clear and dramatic performance improvements by using this gauge.

|

|

|

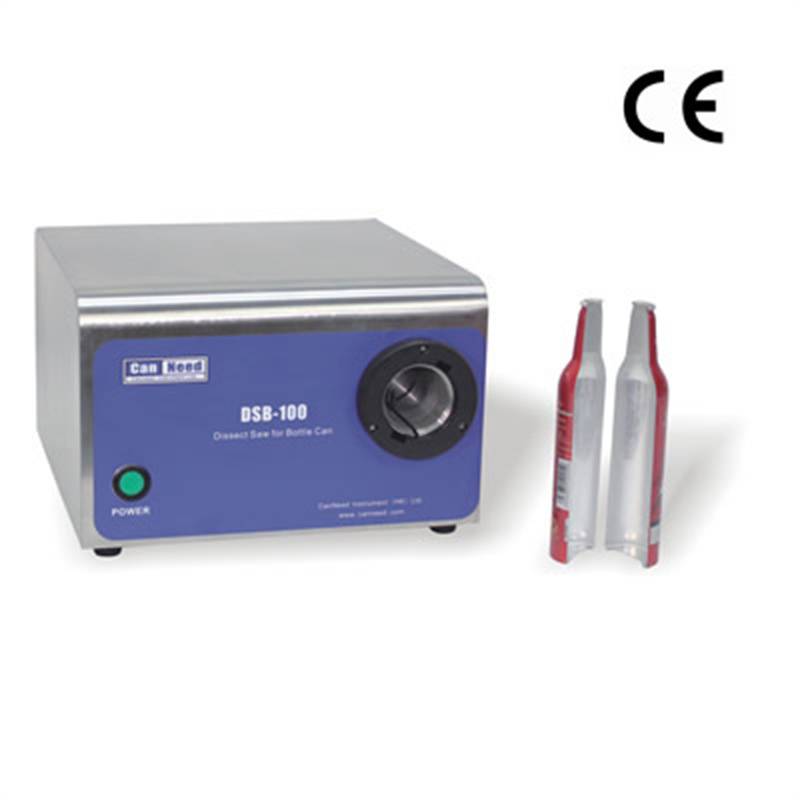

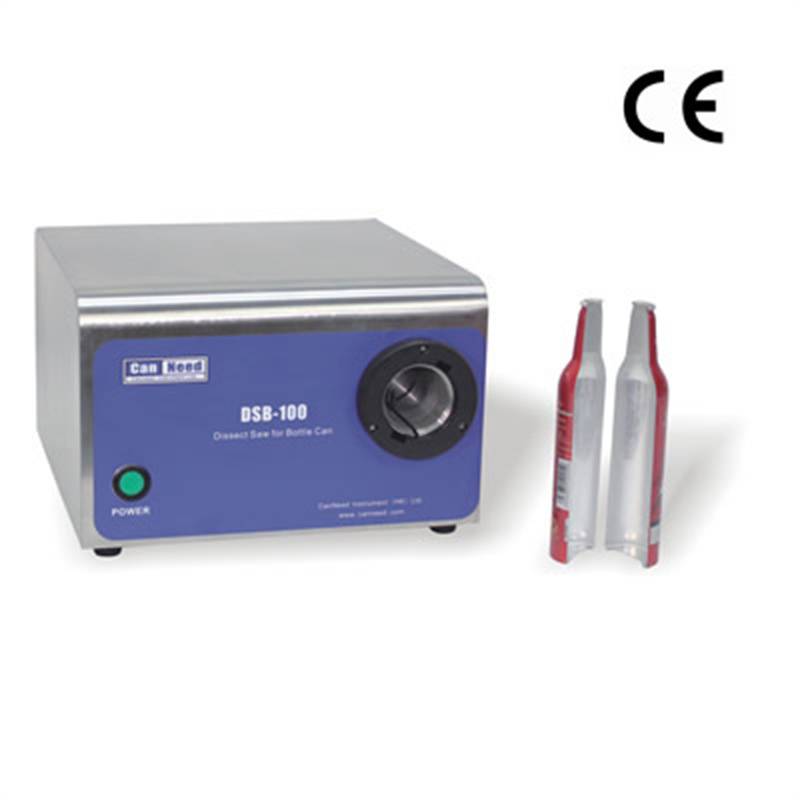

CanNeed-DSB-100 Dissect Saw for Bottle Can

|

|

CanNeed-DSB-100 Dissect Saw for Bottle Can cuts the cans into two half for can inspections. We can observe the corrosion or coating problem inside the can. DSB-100 is provided with a safe design toavoid cutting the finger. The blade is very hard and durable.

|

|

|

CanNeed-CSS-100B Anti-noise Seam Saw

|

|

CanNeed-CSS-100B Anti-noise seam saw is provided with an anti-noise design and a special guide for 2- and 3-piece cans (65 mm dia.). Special seam circular saw with double cut for can double seam inspections. The CanNeed -CSS-100B was specially designed for 2 and 3-piece cans.

The nitrated blades achieve together with the speed of approx. 1.000 r/min. a very plain cut surface. The seam image on VSM 6A Automatic Seam Computer (Video Seam Monitors), and automatic seam measuring systems gets thereby very clear and improves measurement speed and reliability.

|

|

|

CanNeed-CMS-1000 Automatic Measure System for Food Cans

|

|

CanNeed-CMS-1000 Automatic Measure System for Food Cans is used to measure Flange Width, Can Height ,the bead depth of the can body and the bead space distance of the can body of 3-pc can.

|

|

|

CanNeed-AMPT-Line-1000 Automatic Beverage Multi-Parameter Tester

|

|

CanNeed-AMPT-Line-1000 Automatic Beverage Multi-Parameter Tester is used to measure the parameters of PET bottles as follows.

1. Torque

2. Secure seal

3. Pressure resistance / CO2

4. Sealing angle

5. Weight

6. Top load

Above 6 test items can be optionally customized, up to 6 in 1 combination. Fully automatic feeding samples to the testing platforms by conveyor and proceed to testing automatically, avoid any human influence or error.

|

|

|

CanNeed-ASAT-Line-1000 Fully automatic sealing angle tester

|

|

The CanNeed-ASAT-Line-1000 fully automatic sealing angle tester is an unmanned and fully automatic device that detects the marking points on the bottle cap and body, determines the size of the sealing angle, and provides better judgment conditions for the sealing performance of the bottle cap. Determine OK and NG based on the angle value and store the data. Fully automated detection, no human interference, high detection accuracy, high repeatability, all detection data is stored and recorded in software processing, and can be read.

|

|

|

CanNeed-SCT-200 Stress Cracking Tester(26 Stations)

|

|

CanNeed-SCT-200 Digital Stress Cracking Tester(26 Stations) is a special instrument for testing the stress crack resistance of blow-molded PET carbonate bottles. The effect of lye on PET bottom was tested after the production line was cleaned. The 26 stations, each station has a corresponding pressure test, in the set time to observe the PET bottle bottom rupture.

Measurement method: Constant pressure test, simulate the pressure inside the gas-containing bottle, use compressed air to make the pressure inside the PET stabilize at the set pressure, the bottom of the bottle is immersed in lye, observe the damaging effect of lye on the bottom of the bottle.

Measurement method:Measure the value of air pressure, determine whether it is ruptured through the fall of air pressure, remove the sample after the test to observe the damage degree of the sample.

|

|

|

CanNeed-AS-200d Digital AutoShaker Beverage CO2 Calculator

|

|

The "AS-200d Digital AutoShaker Beverage CO2 Calculator" is a patented instrument which is for calculating the carbon dioxide content in the filled drink in glass/PET bottles and cans. The simple operation which guarantees high reproducibility has led to its becoming a significant element of Quality Assurance in the drinks industry.

|

|

|

CanNeed-AS-100 AutoShaker Beverage CO2 Calculator

|

|

The “AS-100 AutoShaker Beverage CO2 Calculator” is a patented instrument which is for calculating the carbon dioxide content in the filled beverage in glass/PET bottles and cans. The simple operation which guarantees high reproducibility has led to its becoming a significant element of Quality Assurance in the drinks industry.

|

|

|

Seam-X-On-Line-T Full Automatic Seam Scanner (Non-destructive & Automatic sampling)

|

Seam-X®-On-Line Automatic Seam Scanner adopts non-destructive measure method to measure the seam dimension. It is applicable to be installed by pass the production line, taking the samples and measuring them.

Measure Items: Seam Length, Body Hook, End Hook, Overlap, %Overlap, Seam Gap, %Body Hook Butting, and %End Hook Butting.

It’s applicable to measure cans of various materials. Combination of can body and the end can be following: (1) Aluminum & Aluminum; (2) Tin & Tin.

Seam-X®-On-Line can work together with the seam thickness gauge and countersink gauge, to make up a complete measure system for the double seam.

If configured with identification sampling system, it can make the result of every can correspond to the related seamer head.

|

|

|

Seam-X-On-Line-T Full Automatic Seam Scanner (Non-destructive & Automatic sampling)

|

|

Seam-X®-On-Line Automatic Seam Scanner adopts non-destructive measure method to measure the seam dimension. It is applicable to be installed by pass the production line, taking the samples and measuring them.

Measure Items: Seam Length, Body Hook, End Hook, Overlap, %Overlap, Seam Gap, %Body Hook Butting, and %End Hook Butting.

It’s applicable to measure cans of various materials. Combination of can body and the end can be following: (1) Aluminum & Aluminum; (2) Tin & Tin.

Seam-X®-On-Line can work together with the seam thickness gauge and countersink gauge, to make up a complete measure system for the double seam.

If configured with identification sampling system, it can make the result of every can correspond to the related seamer head.

|

|

|

SeamSight-C Full Automatic Seam Monitor

|

|

The SeamSight® system is equipped with the new seam measuring software SeamSight® Professional Software. Which will do the line positioning automatically and the measurement to be finished within 1 second!

Use the CanNeed SPC data collection system, The actual seam thickness, actual countersink, etc., can be transferred to the computer automatically.

The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

With CanNeed Automatic Seam Sight® Monitor, press only one key “Auto Measure” to do the line positioning automatically and the measurement to be finished within 1 second! It can measure the seam dimension automatically, efficiently, simply and also avoid operator mistake. Use the CanNeed SPC data collection system (CSG-200 countersink gauge & STG-200D seam thickness gauge), the actual seam thickness, actual countersink, etc., can be transferred to the computer automatically. Such data can generate a report together with other data, improving the process.

|

|

|

CanNeed-ADER-C6000 Automatic Digital Enamel Rater for Cans

|

|

CanNeed-ADER-C6000 is a fully automatic digital enamel rater with unattended operation. It’s is used to measure the coverage, the compactness and the electric current value of the enamel coating inside the beverage cans. The contents will erode the metallic material and affect the quality and storage of products if the enamel coating inside the cans is not integrated.

The machine adopted fully automatic inspecting technology, more efficient and more effectively reducing the human errors. It is the standard for evaluating can quality in can-making industry.

|

|

|

A-SeamSight-1000 Automatic Seam Monitor(Automatic Cutting and Measurement)

|

|

“A-SeamSight-1000 Automatic Seam Monitor(Automatic Cutting and Measurement)” is used to measure the seam quality of cans.

Automatic Seam Monitor(Automatic Cutting and Measurement)Equipped with Golden Lens® video capture device which interference-free of external light source and ensured the high image definition.

|

|

|

A-SeamSight-1000 Automatic Seam Monitor(Automatic Cutting and Measurement)

|

|

“A-SeamSight-1000 Automatic Seam Monitor(Automatic Cutting and Measurement)” is used to measure the seam quality of cans.

Automatic Seam Monitor(Automatic Cutting and Measurement)Equipped with Golden Lens® video capture device which interference-free of external light source and ensured the high image definition.

|

|

|

A-SeamSight-1000 Automatic Seam Monitor(Automatic Cutting and Measurement)

|

|

“A-SeamSight-1000 Automatic Seam Monitor(Automatic Cutting and Measurement)” is used to measure the seam quality of cans.

Automatic Seam Monitor(Automatic Cutting and Measurement)Equipped with Golden Lens® video capture device which interference-free of external light source and ensured the high image definition.

|

|

|

CanNeed-MDER-C2 Multi-station Digital Enamel Rater for Cans

|

|

CanNeed-MDER-C2 is used to measure the coverage, the compactness and the electric current value of the enamel coating inside the food and beverage cans. The contents will erode the metallic material and affect the quality and storage of products if the enamel coating inside the cans is not integrated. The machine adopted semi-automatic technology, more efficient and more effectively reducing the human errors. CanNeed-MDER-C2 is the standard of can making industry.

|

|

|

CanNeed-MDER-C2 Multi-station Digital Enamel Rater for Cans

|

|

CanNeed-MDER-C2 is used to measure the coverage, the compactness and the electric current value of the enamel coating inside the food and beverage cans. The contents will erode the metallic material and affect the quality and storage of products if the enamel coating inside the cans is not integrated. The machine adopted semi-automatic technology, more efficient and more effectively reducing the human errors. CanNeed-MDER-C2 is the standard of can making industry.

|

|

|

CanNeed-ADER-C3100 Automatic Digital Enamel Rater for Cans

|

|

CanNeed-ADER-C3100 is a fully automatic digital enamel rater with unattended operation. It’s is used to measure the coverage, the compactness and the electric current value of the enamel coating inside the beverage cans. The contents will erode the metallic material and affect the quality and storage of products if the enamel coating inside the cans is not integrated. The machine adopted fully automaticinspecting technology, more efficient and more effectively reducing the human errors. It is the standard for evaluating can quality in can-making industry.

|

|

|

CanNeed-ADER-C3100 Automatic Digital Enamel Rater for Cans

|

|

CanNeed-ADER-C3100 is a fully automatic digital enamel rater with unattended operation. It’s is used to measure the coverage, the compactness and the electric current value of the enamel coating inside the beverage cans. The contents will erode the metallic material and affect the quality and storage of products if the enamel coating inside the cans is not integrated. The machine adopted fully automaticinspecting technology, more efficient and more effectively reducing the human errors. It is the standard for evaluating can quality in can-making industry.

|

|

|

CanNeed-ADER-C3100 Automatic Digital Enamel Rater for Cans

|

|

CanNeed-ADER-C3100 is a fully automatic digital enamel rater with unattended operation. It’s is used to measure the coverage, the compactness and the electric current value of the enamel coating inside the beverage cans. The contents will erode the metallic material and affect the quality and storage of products if the enamel coating inside the cans is not integrated. The machine adopted fully automaticinspecting technology, more efficient and more effectively reducing the human errors. It is the standard for evaluating can quality in can-making industry.

|

|

|

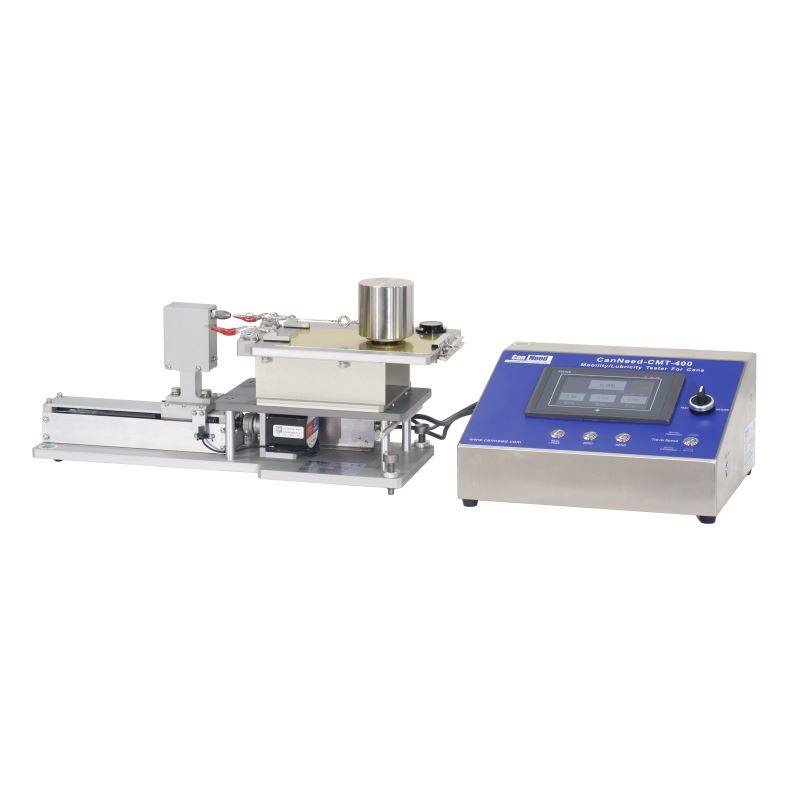

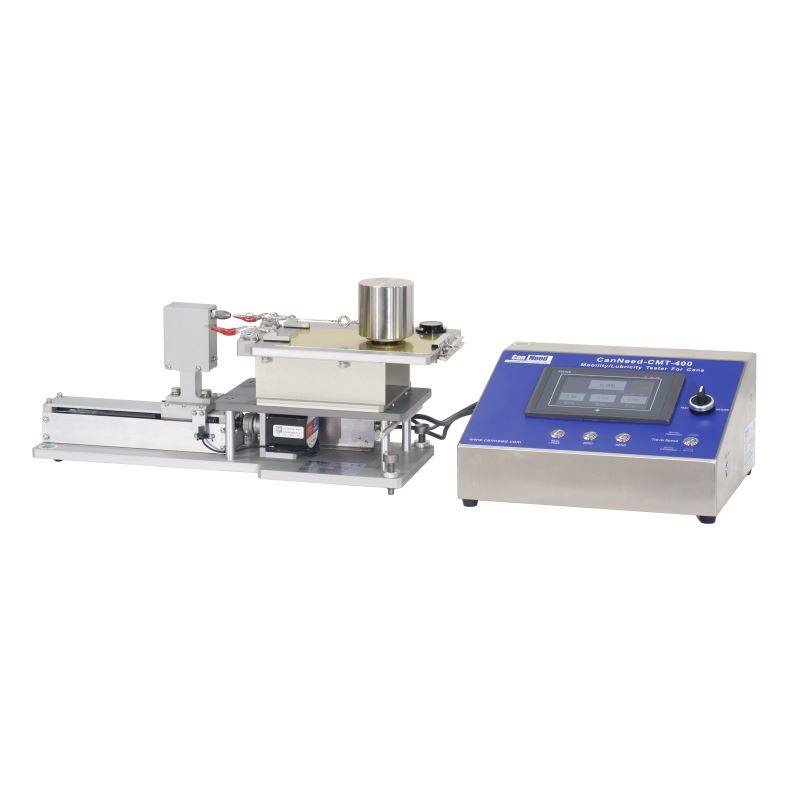

CanNeed-CMT-400 Mobility / Lubricity Tester for Cans (Digital)

|

|

CanNeed-CMT-400 Mobility / Lubricity Tester for Cans is for measuring the coefficient of sliding friction of can body and bottom. It can also measure the coefficient of sliding friction of blanks.

|

|

|

CanNeed-CMT-400 Mobility / Lubricity Tester for Cans (Digital)

|

|

CanNeed-CMT-400 Mobility / Lubricity Tester for Cans is for measuring the coefficient of sliding friction of can body and bottom. It can also measure the coefficient of sliding friction of blanks.

|

|

|

CanNeed-PFT-100 Pull Force Tester for Drums

|

|

CanNeed-PFT-100 Pull Force Tester for Drums is used to measure the strength of the lifting ring on the drum. With the strength test for the ring, the ring or the its installed part should not break nor be apart.

|

|

|

CanNeed-ZM-1800-D Digital Body Blank Gauge

|

|

CanNeed-ZM-1800-D Digital Body Blank Gauge is made to measure the length, width and perpendicularity (angle) and the diagonal on the blank Sheets.

|

|

|

CanNeed-CLT-300 Leak Tester for can

|

|

The “CanNeed-CLT-600 Leak Tester for can “ is used for checking the leakage of 3-piece cans in a water bath. It can test six cans in each test.

Testing method: Place the sample cans to the platen, the cans will be fixed by the magnet disc plate, clamp the cans to seal the top, then submerge the cans into water and apply pressure to the cans.

Observer the can body to see whether there are bubbles come out, if bubbles come out from the can body constantly, that means the sample cans leak.

During the testing, operator is able to turn the samples over for easy observing the can top, can bottom, can body and welding line.

The test procedure is performed semi-automatically and the tester is suitable for different sizes of round 3-piece cans.

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|