|

| |

Product Classification : All Products

|

|

CanNeed-STR-100A Seam Stripper

|

The automatic “CanNeed-STR-100 Seam Stripper” is a sensible, affordable, teardown method to prepare the double seam teardown analysis. One fast, safe teardown operation without damaging or distorting the cover hook. Reduce teardown time for more frequent inspections. Tooling quick change in few seconds. Models are available for most common can sizes of beverage and food cans. When ordering, the end diameter and can height must be specified so that the appropriate change parts are included. Efficient cut and strip both aluminium and steel cans in a single motion. 10 seconds per can. Eliminates the repetitious actions by hand.

An important part of any seam evaluation is the actual teardown of the can seam to determine tightness or wrinkled rating.

|

|

|

CanNeed-TT-210 Digital Torque Tester

|

|

Applications: Food-industry / Cosmetic/ Pharmaceutical / Chemical / Metrology

The CanNeed-TT-210 Digital Torque Tester are specially designed for testing the cap closing and opening torque value of the bottled products. Its excellent performance makes it the industrial standard.

The clients can also choose the measuring software by orders.

|

|

|

CanNeed-SCT-210 Stress Cracking Tester

|

|

CanNeed-SCT-210 Stress Cracking Tester is a special instrument for testing the stress crack resistance of blow-molded PET carbonate bottles.The effect of lye on PET bottom was tested after the production line was cleaned.The 26 stations, each station has a corresponding pressure test, in the set time to observe the PET bottle bottom rupture.

Measurement method: Constant pressure test, simulate the pressure inside the gas-containing bottle, use compressed air to make the pressure inside the PET stabilize at the set pressure, the bottom of the bottle is immersed in lye, observe the damaging effect of lye on the bottom of the bottle.

Measurement method: Measure the value of air pressure, determine whether it is ruptured through the fall of air pressure, remove the sample after the test to observe the damage degree of the sample.

|

|

|

CanNeed-CPRT-1000 Carton Pressure Resistance Tester

|

|

CanNeed-CPRT-1000 Carton Pressure Resistance Tester is a kind of equipment used to test the compression resistance of cartons. It’s mainly used to test the compression strength of packaged products, in order to prevent deformation, damage and other adverse phenomena caused by insufficient packaging strength in the process of using, handling, stacking, storage and transportation.

There are three test modes applied by CanNeed-CPRT-1000: Pressure Resistance Test, Constant Value Test and Stacking Test.

The Pressure Resistance Test mode and measure the ultimate compressive strength and deformation of the cartons. The Constant Value Test mode and measure whether the carton can meet the requirements of the set fixed force value and deformation amount. And the Stacking Test can simulate the stacking status of the warehouse and test the stacking performance of the carton.

|

|

|

CanNeed-PAT-100 Ink Printing Abrasion Tester

|

|

CanNeed-PAT-100 Ink Printing Abrasion Tester is used for testing the abrasion wearing resistance of printing ink layer, PS plate photosensitive layer and surface coating of related products. It can effectively analyze the problems of poor abrasion wearing resistance, ink layer shedding, low printing resistance of PS plate and poor coating hardness of other products, etc. It can solve the problems of poor wear resistance, low friction resistance and easy shedding of the ink layer of printed products. Through the test, we can effectively control the production process and avoid the loss of return due to poor quality.

|

|

|

CanNeed-ASST-600 Automatic Secure Seal Tester

|

|

CanNeed-ASST-600 Automatic Secure Seal Tester is specially designed to test the seal integrity of PET bottles, glass bottles and the crown caps after packaging, prevent gas leakage and effectively control the sealing quality of the packaging cap. Comply with the national standard, line standard: GB/T 17876-2010 packaging container plastic anti-theft bottle cap. The ASST series products are widely used in beverage and brewing industries.

|

|

|

CanNeed-ASST-600 Automatic Secure Seal Tester

|

|

CanNeed-ASST-600 Automatic Secure Seal Tester is specially designed to test the seal integrity of PET bottles, glass bottles and the crown caps after packaging, prevent gas leakage and effectively control the sealing quality of the packaging cap. Comply with the national standard, line standard: GB/T 17876-2010 packaging container plastic anti-theft bottle cap. The ASST series products are widely used in beverage and brewing industries.

|

|

|

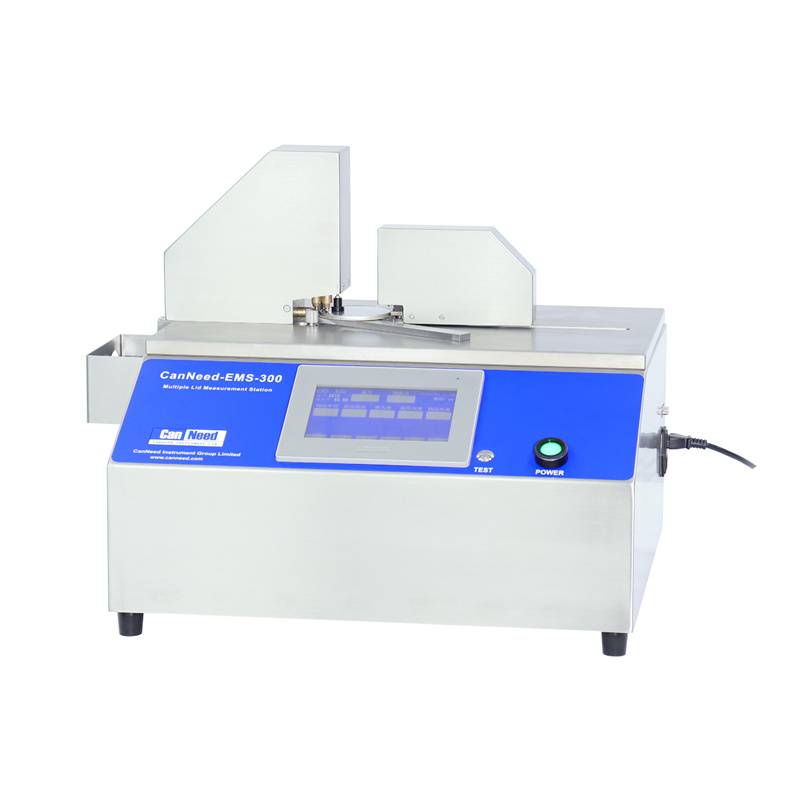

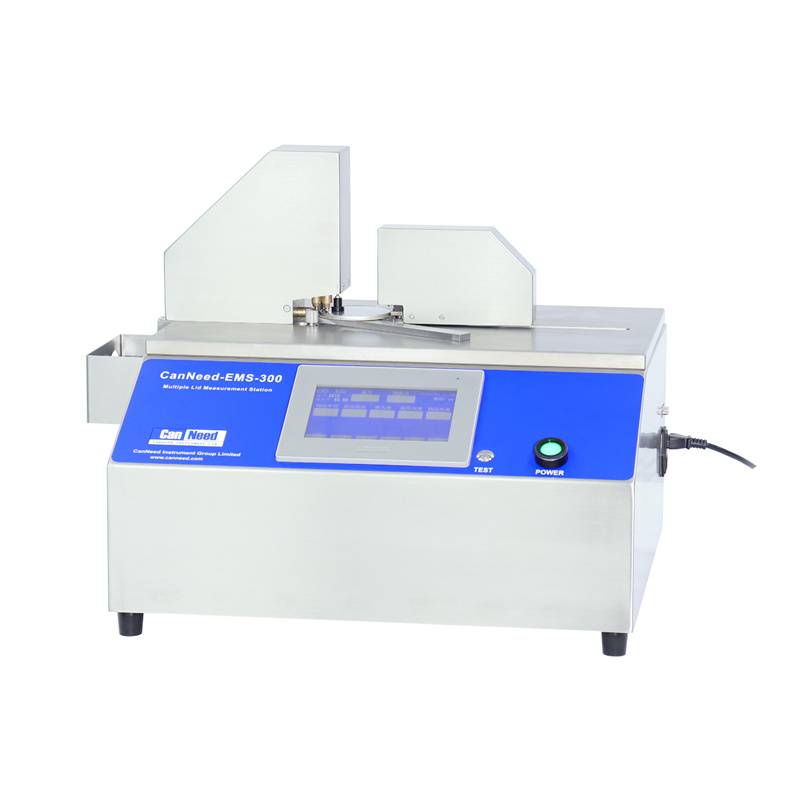

CanNeed-EMS-300 Multiple Lid Measurement Station

|

|

CanNeed-EMS-300 Multiple Lid Measurement Station is used to measure the parameters of the can end as follows:

A.End curl outer diameter

B.End curl height

C.End countersink

D.End curl opening

E.End curl width

F.End curl length

G.End curl inner diameter

H.Chuck adapting diameter

J.Thimble depth

|

|

|

CanNeed-CDT-100 Upside Down Drop Tester for Can End

|

|

Verify the deformation of the can lid when subjected to drop impact tests at specified heights and angles.

|

|

|

Standard Bottle of Torque Verification System

|

|

CanNeed-BTM-200 Standard Bottle of Torque Verification System is designed with the principle of constant magnetic force and can be reset automatically. It is suitable for the torque calibration of torque tester for all kinds of PET bottles, and can also be used for the calibration of all kinds of capping equipment in the production line. The instrument is a universal calibration tool, easy to use.

|

|

|

CanNeed-BCC-7001 Digital Beverage CO2 Calculator

|

|

CanNeed-BCC-7001 Digital Beverage CO2 Calculator is for measuring the CO2 content of the glass bottled, canned or PET bottled beer and other carbonated beverage. The operation is simple, when the measurement is carrying on, the BCC-7001 will calculate the CO2 automatically.

After the pierce head punctured into the container, users shake the device together with the sample by hand, then start the device, it will automatically calculate the temperature and pressure, and the result will be displayed on the screen.

CanNeed-BCC-7001 Digital Beverage CO2 Calculator is applicable for different size of glass bottle, can and PET bottle.

If combine the IAM Air Meter for measuring, it would be able to measure the bottle neck air and total air content at the same time when measuring the CO2 Content.

|

|

|

CanNeed-BCC-7001 Digital Beverage CO2 Calculator

|

|

CanNeed-BCC-7001 Digital Beverage CO2 Calculator is for measuring the CO2 content of the glass bottled, canned or PET bottled beer and other carbonated beverage. The operation is simple, when the measurement is carrying on, the BCC-7001 will calculate the CO2 automatically.

After the pierce head punctured into the container, users shake the device together with the sample by hand, then start the device, it will automatically calculate the temperature and pressure, and the result will be displayed on the screen.

CanNeed-BCC-7001 Digital Beverage CO2 Calculator is applicable for different size of glass bottle, can and PET bottle.

If combine the IAM Air Meter for measuring, it would be able to measure the bottle neck air and total air content at the same time when measuring the CO2 Content.

|

|

|

CanNeed-Inpack-3000 CO2 Tester and Pressure Tester

|

|

The “CanNeed-Inpack 3000 CO2 Tester and Pressure Tester” is used to measure the CO2 content in carbonated beverages filled in glass and PET bottles and cans. It is corresponding to “GB/T 4928 – 2001 Brewing Analysis Methods” and “GB/T 10792 – 1995 Carbonated Beverage Analysis Methods”. Therefore, the machine is widely used by Quality and Technical Supervision Bureau and beverage enterprises.

CanNeed-Inpack 3000 can measure the total pressure in brewery or beverage. Applied with temperature measurement, the CO2 content is determined by means of the CO2 slide rule or temperature/pressure relationship charts. It is applicable to the bottles or cans with different sizes.

|

|

|

CanNeed-Inpack-3000 CO2 Tester and Pressure Tester

|

|

The “CanNeed-Inpack 3000 CO2 Tester and Pressure Tester” is used to measure the CO2 content in carbonated beverages filled in glass and PET bottles and cans. It is corresponding to “GB/T 4928 – 2001 Brewing Analysis Methods” and “GB/T 10792 – 1995 Carbonated Beverage Analysis Methods”. Therefore, the machine is widely used by Quality and Technical Supervision Bureau and beverage enterprises.

CanNeed-Inpack 3000 can measure the total pressure in brewery or beverage. Applied with temperature measurement, the CO2 content is determined by means of the CO2 slide rule or temperature/pressure relationship charts. It is applicable to the bottles or cans with different sizes.

|

|

|

CanNeed-PCD-100 Pressure Calibration Device

|

|

The “CanNeed-PCD Pressure Calibration Device” is a dedicated precision instrument for calibrating CO2 pressure gauges and digital pressure meters. It can effectively improve the accuracy of CO2. CanNeed-PCD Pressure Calibration Device has a compact and recognizable design, is user-friendly and can multi-functionally be applied in breweries and soft drink industry. The calibration of measurement devices, more and more, needs to be traceable, because laboratory analyses depend on it. It is used with compressed air or other gas as medium.

|

|

|

CanNeed-DER-400 Digital Enamel Rater

|

|

CanNeed-DER-400 Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

CanNeed-DER-400 is the industry standard. The new CanNeed Enamel Rater DER-400 instrument test the coverage of the enamel coating inside food and beverage cans, aerosol-cans and also different kinds of ends. It displays an index of the amount of metal exposed by incomplete enamel coverage on a clear, easily read digital LED.

|

|

|

CanNeed-CTG-310 Coating Thickness Gauge

|

|

CanNeed-CTG-310 Coating Thickness Gauge is used to test the coating thickness(coating weight per unit area, g/m2). When equipped with “Hover Probe”, it can measure the coating thickness of plate sheets. When equipped with can body testing clamp, it can test the coating thickness of can body.

Use standard coating plate (sample with known weight, g/m2) calibration equipment to test different

types of coatings. Test result and coating type number will display on the screen and the data will be output to PC with RS232.

|

|

|

CanNeed-CND-TRK-300 Oven Temperature Tracker

|

|

The “CanNeed-TRK-300 Oven Temperature Tracker” is a professional oven temperature curve inspection system for the coating industry, it is including the data logger, heat insulation case, software (Chinese / English) and thermocouples.

"CanNeed-TRK-300 Oven Temperature Tracker” is use to pass through the oven with the solidifying products, and record down the real temperature during the process. The logger is in the centre of the system. Heat insulation case is for protecting the logger from over heat by the oven. When passing through the oven, the CanNeed-TRK-300 Oven Temperature Tracker will record down the real time temperature of the solidifying products through the 5 thermocouples which were connected to the products, and one thermocouple is for recording the air temperature of the oven. After the recording process was finished, use the CND_TRK Software to analyze the temperature data and generate the detail reports.

|

|

|

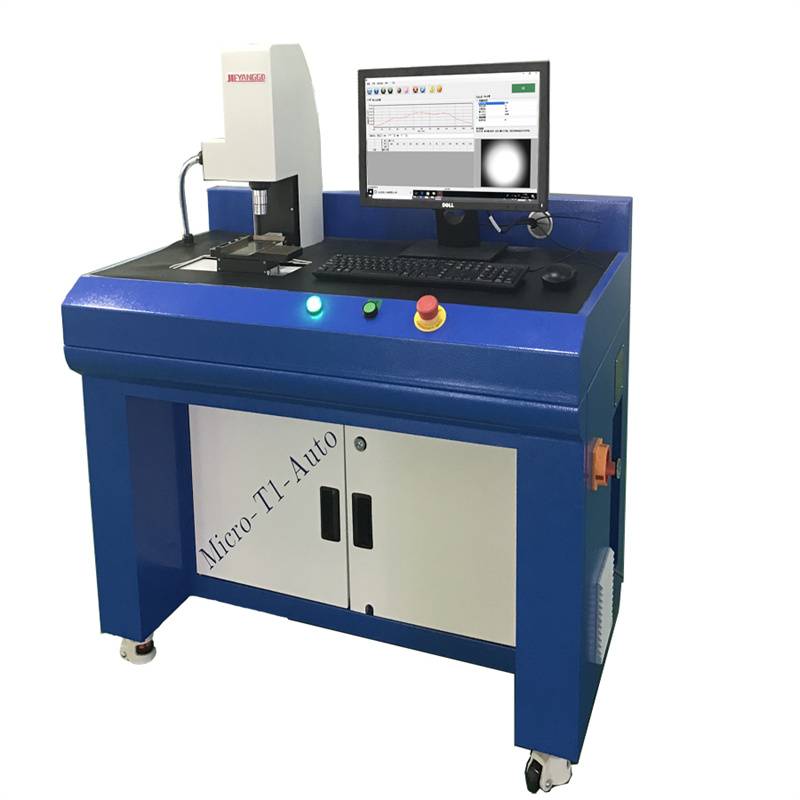

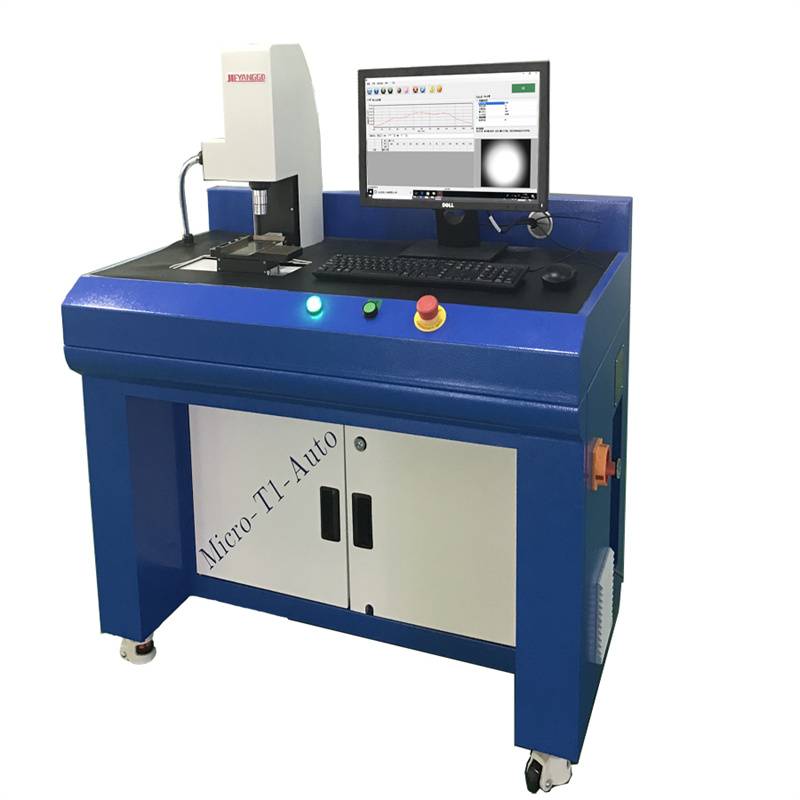

Micro-T1-Auto

|

|

|

|

|

CanNeed-TRT-2100

|

|

|

|

|

CanNeed-TRT-2030

|

|

|

|

|

CanNeed-TRT-3020

|

|

|

|

|

X-Chip-A380

|

|

|

|

|

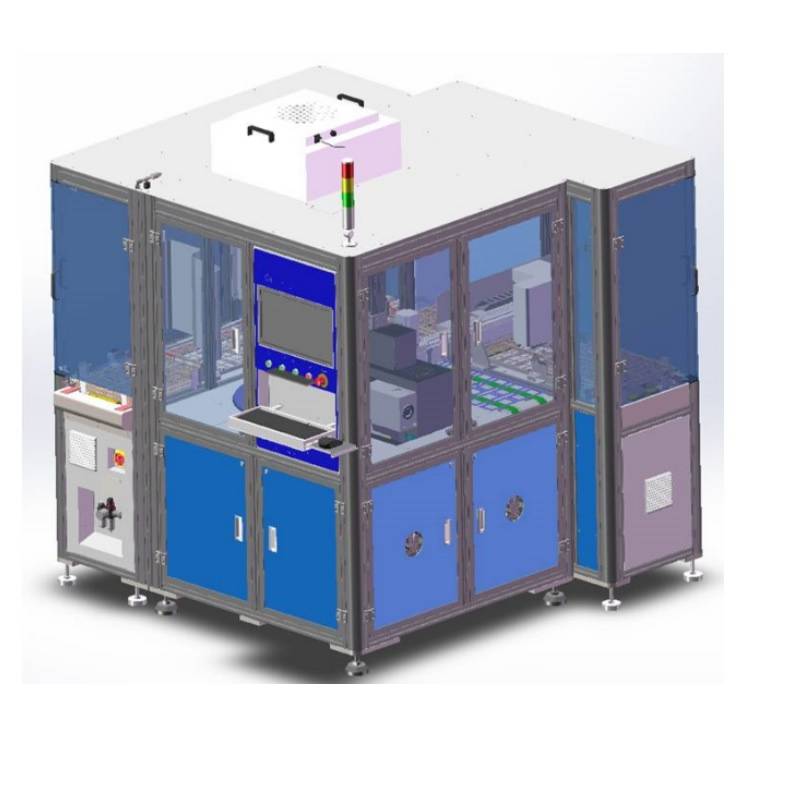

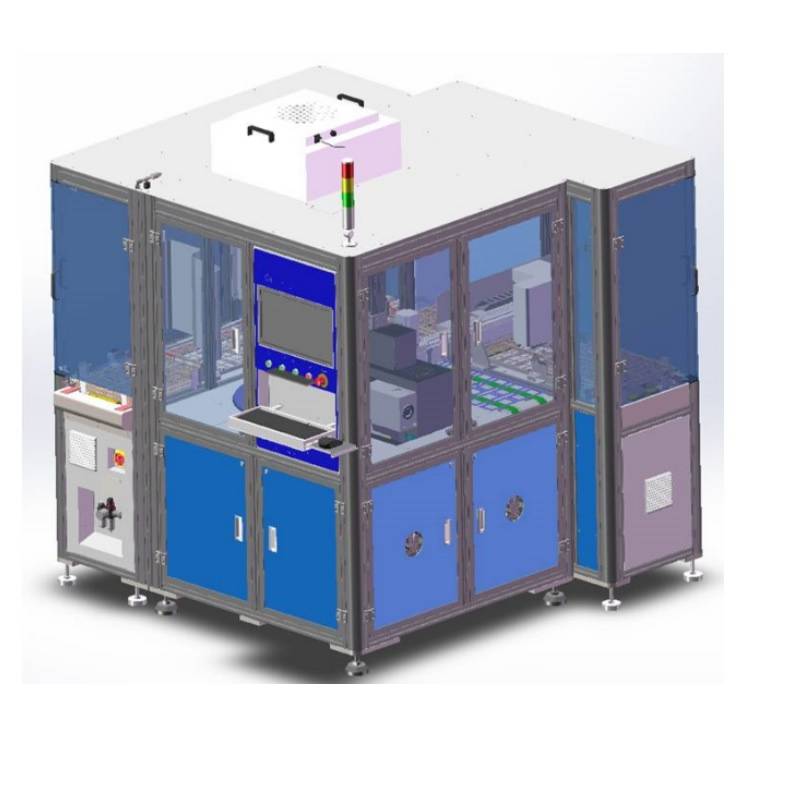

CanNeed-ASST-Line-1000 Automatic Secure Seal Tester

|

|

CanNeed-ASST-Line-1000 Automatic Secure Seal Tester is used to test the seal integrity of finished products by unattended operation, it effectively controls the sealing properties and prevent gas leakage after packaging. Therefore it is widely used in beverage industry and meets to international inspection standards《GBT 17876-2010 Packaging Container - Plastic Anti-Theft Bottles》.

|

|

|

CanNeed-ATPO-1000 Automatic Beverage Total Package Oxygen Analyzer

|

|

|

|

|

CanNeed-ATPO-1000 Automatic Beverage Total Package Oxygen Analyzer

|

|

|

|

|

CanNeed-ATT-Line-1000 Automatic Torque Tester (Automatic Sampling)

|

Bottle packaging is one of the common packaging forms of food, beverage and drugs. The torque value of opening and closing is one of the key controlling parameters on production line or offline. The appropriate torque value has a great influence on the transportation and final consumption of the products. It is one of the key product indicators which needs to be controlled by enterprises.

CanNeed-ATT-Line-1000 Automatic Torque Tester is the ideal instrument to do this test. It can be placed maximum 12 samples, then automatically sampling by conveyor belt. The sample will be measured automatically once arrived at the measurement station and avoid the influence of human factors.

|

|

|

CanNeed-ATT-Line-1000 Automatic Torque Tester (Automatic Sampling)

|

|

Bottle packaging is one of the common packaging forms of food, beverage and drugs. The torque value of opening and closing is one of the key controlling parameters on production line or offline. The appropriate torque value has a great influence on the transportation and final consumption of the products. It is one of the key product indicators which needs to be controlled by enterprises.

CanNeed-ATT-Line-1000 Automatic Torque Tester is the ideal instrument to do this test. It can be placed maximum 12 samples, then automatically sampling by conveyor belt. The sample will be measured automatically once arrived at the measurement station and avoid the influence of human factors.

|

|

|

CanNeed-ABPT-1000 Automatic Ramp Pressure Tester

|

|

CanNeed-ABPT-1000 Ramp Pressure Tester is used to test the internal pressure resistance of glass bottles, and can meet two different test requirements of passing and burst modes.

|

|

|

CanNeed-FEBI-2000 Front Empty Bottle Inspection

|

|

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|