Seam-X®-On-line X-Ray Automatic Seam Scanner” adopts non-destructive measurement method to measure the seam quality, suitable for measuring the aluminum cans, steel cans , aluminum-iron composite cans and etc. It’s applicable for online in producing department. It’s a non-destructive, cost saving, accurate measurement and automatic equipment which can be installed on the production line to improve the sampling frequency.

Measure Items: Seam Length, Body Hook, End Hook, Overlap, %Overlap, Seam Gap, %Body Hook Butting, and %End Hook Butting.

It’s applicable to measure cans of various materials. Combination of can body and the end can be following: (1) Aluminum & Aluminum; (2) Tin & Tin.

Seam-X®-On-Line can work together with the seam thickness gauge and countersink gauge, to make up a complete measure system for the double seam.

If configured with identification sampling system, it can make the result of every can correspond to the related seamer head.

Sample materials Combination of can body and the end: (1) Aluminum & Aluminum; (2) Tin & Tin

Sample sizes Diameter: 200 (50mm)-211 (67 mm); Height: ≤168mm

Measure items Seam Dimension: Seam Length, Body Hook, End Hook, Overlap, %Overlap, Seam Gap, %Body Hook Butting, %End Hook Butting

Unit Inch, mm

Language English & Chinese

Accuracy +/- 0.01 mm

Resolution 0.001 mm

Data output Ethernet, ASCII, TXT, SQL, DBI

Power supply 100-240VAC, 50/60 Hz

Air Supply 0.4-0.6MPa

Dimensions L1400 x W1500 x H2000mm

Weight Approx. 2000kg

CanNeed-Seam-X-On-line X-Ray

Automatic Seam Scanner

(Non-destructive)

“Efficient, Cost saving, High Sampling frequency”

|

l Non-destructive measurement, avoid wasting samples

l Non-destructive measurement, avoid environmental pollution and save handling charges

l High sampling frequency, reduce the isolation inferior

l High sampling frequency, cost saving

l Can track the chucks corresponding to the unqualified products

l 360-degree fully scan measurement

l Can be suitable for various types of cans

l Higher accuracy

l Avoid manual measurement error

l Durable

l Accord with the worldwide safety standards

|

|

Purpose:

The “CanNeed-Seam-X-On-Line X-Ray Automatic Seam Scanner” adopts non-destructive measurement method to measure the seam quality, suitable for measuring the aluminum cans, steel cans , aluminum-iron composite cans and etc. It’s applicable for online in producing department. It’s a non-destructive, cost saving, accurate measurement and automatic equipment which can be installed on the production line to improve the sampling frequency.

|

|

Equipment Outline:

● Outline dimension:

<!--[if !vml]--> <!--[endif]-->

<!--[endif]-->

● Production line distribution (Case one):

Technical data:

l Applicable for online in producing department; batch sampling test based on the preset time.

l Sampling interval: set the shortest time as sampling 12 cans/ batch in 1 minute

l Automatically input samples and measure samples, no need for human operation

l Accuracy:0.01mm

l 360-degree fully scan measurement, no blind spot detection

l Machine inspection beat: 5~8 second/PCS

l Load: production time calculation for 22 hours one day; Measuring capacity: 22(h) X 3600 (s) ÷ 5~8 (s) ≈10 K PCS/day. It’s a stable and reliable equipment to the continuous detection.

l Adopts closed loop control. The seam structure data of each can is separately corresponding to the chucks of seamer. Able to track the chucks corresponding to the unqualified products, saving a lot of time to find out the problems and adjust the seamer.

l Automatically get rid of the inferiors.

Measuring Process:

Take samples from the online signal automatic production line

Transport samples to the detection entrance  Automatic sampling to the rotating disk positioning

Automatic sampling to the rotating disk positioning

Adopt non-destructive X-ray to go through the required inspection stations

360-degree fully scan measurement and take figures  Images can be auto analyzed by software

Images can be auto analyzed by software

Qualified products

Qualified products

Analyze data to the server

Analyze the status of seamer according to the data report  Inferiors

Inferiors

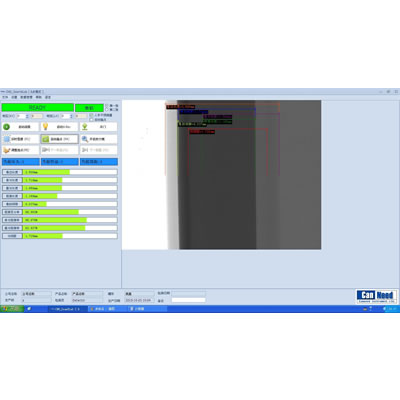

Seam-X-On-Line Software features

1) The seam overlap and tightness can be measured at the same time, 10 Measuring Items: Seam Length, Body Hook Length, End Hook Length, Overlap Length, Seam Gap, Overlap Rate, Body Hook Lapping Rate, End Hook Lapping Rate, On-screen Seam Thickness and Tightness

2) Report format can be customized, flexible for different report styles of different companies

3) Software adopted data base management system, measurement results and images are saved in the data base, users can facilitate inquires

4) Graph chart statistic function, automatically analyze and compare the measurement results

5) Users can review or re-measure the saved projects at any time

6) Data can be exported as an Excel file

7) Predefine various qualification standards, can judge and warn automatically whether the results are qualified in every measure

8) Measurement results and label lines can be marked directly on the image, results will be also displayed in corresponding field on the screen

9) Seam image can be printed and stored, facilitate communication with the production department or canning factories, no need to retain the sample cans

10) Provided with calibration piece, users can calibrate at any time and set the calibration password

|

Data base keep each measurement result and image ,convenient for checking

|

Multiple statistic charts ,automatically analyze

|

Seam Monitor development history:

|

1st Generation

|

2nd Generation

|

3rd Generation

|

4th Generation

|

5th Generation

|

|

Dial Gauge

|

Digital data displaying

|

Manual Line positioning

|

Auto Line positioning and data collection, interference-free of external light source

|

Non-destructive

|

|

|

|

|

|

Seam-X-On-line X-Ray Automatic Seam Scanner

|

<!--[endif]-->

<!--[endif]-->

Automatic sampling to the rotating disk positioning

Automatic sampling to the rotating disk positioning

Images can be auto analyzed by software

Images can be auto analyzed by software

Inferiors

Inferiors

粤公网安备44120302000118号

粤公网安备44120302000118号