|

| |

Product Classification : All Products

|

|

CanNeed-ASS-100 Angle Swinging Shaker

|

The CanNeed-ASS-100 Angle Swinging Shaker is used to shake up the samples,especailly for extraction testing.Put the sample into the conical flask,and clamp the conical flask,then set the time and frequency to start shaking.

The device adpot a 20mm reciprocating shaking way,which ensure the sample is fully mixed.

|

|

|

CanNeed-ISD-3000 Piercing and Sampling Device

|

|

The “CanNeed-ISD-3000 Piercing and Sampling Device” is for sampling from the bottled or canned products. Place the beverage onto the base, press down the handle and the piercing will be done. After extending the piercing needle into the bottom of samples, under the pressure from the CO2 outside, the liquid will flow into the measuring instrument.

|

|

|

CanNeed-GMT-100 Beverage CO2 Meter / Gehaltemeter

|

|

The “CanNeed-GMT-100 Portable Beverage CO2 Meter” is common in breweries and soft drink industry to frequently measure the CO2 content during production. It enables a fast and accurate determination of the CO2 content in beer and carbonated drinks, either directly sampled within the production process (from e.g. tanks, pipes) of thereafter (from e.g. kegs). It only takes 3 minutes for one test, repetitive and durable.

Equipped with a manometer and a thermometer, the CO2 content can be quickly determined by CanNeed-GMT-100. Therefore, CanNeed-GMT-100 is widely applied in brewery and soft drink industries.

CanNeed-GMT-100 is designed to measure CO2 content based on Henry’s Law. When the sampling is finished, it will start electrolysis process automatically. The pressure can be read from the manometer and the temperature from the thermometer. By means of a slide rule, the CO2 content can be quickly determined.

|

|

|

CanNeed-SDF-100 Sampling Device Filler

|

|

The CanNeed-SDF-100 Sampling Device Filler is combined with CanNeed-FST-100 TPH Foam Stability tester.

CanNeed-SDF-100 Sampling Device Filler is used for taking large brewery cans and pipelines to take samples of wine in the beer manufactory, in order to avoid foaming, so that to measure the beer foam stability of sample cans in the laboratory.

|

|

|

CanNeed-BT-100 Bottle Turner

|

|

CanNeed-BT-100 Bottle Turner is used for shaking up the bottled or canned samples. Set the shaking time, and clamp the samples into the clamp. After starting the equipment, the samples will be shaken and tumbled automatically until it reaches the set time.

|

|

|

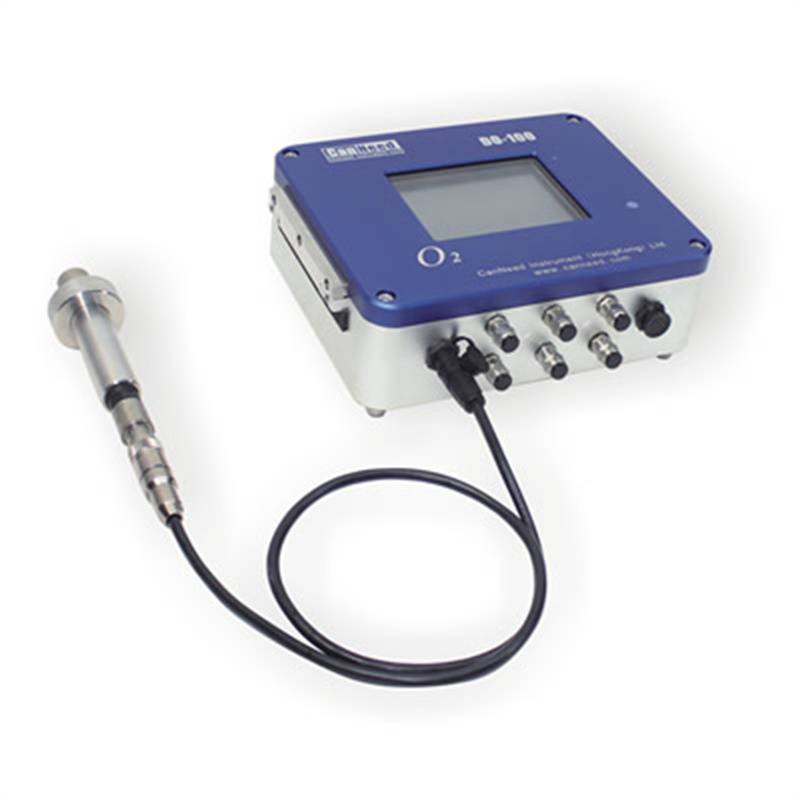

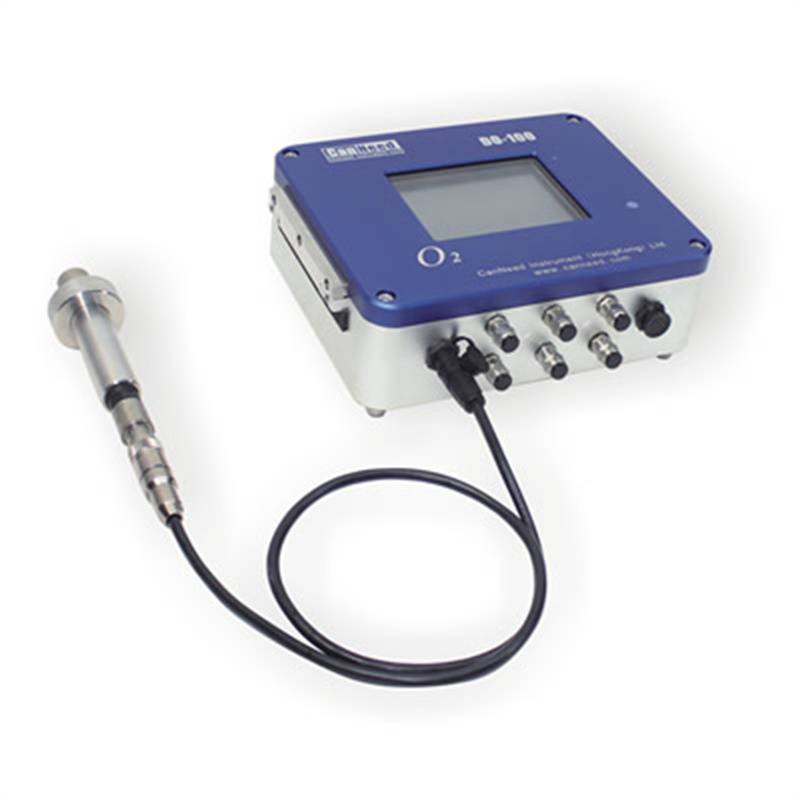

CanNeed-DO-100 Dissolved Oxygen Meter (on-line)

|

CanNeed-DO-100 Dissolved Oxygen Meter (on-line) is a special design for the beverage, power plants, electronic, chemical and water treatment industries. Its measurement data can be used for a professional computer software storage, inquire about, statistics can be print out on paper, also can be connected to a real-time tracking printer.

CanNeed-DO-100 Dissolved Oxygen Meter (on-line) adopts the whole aluminum manufacturing, multi-layer waterproof design, touch screen as the input, so that it has the advantages of simple operation, easy and less maintenance!

|

|

|

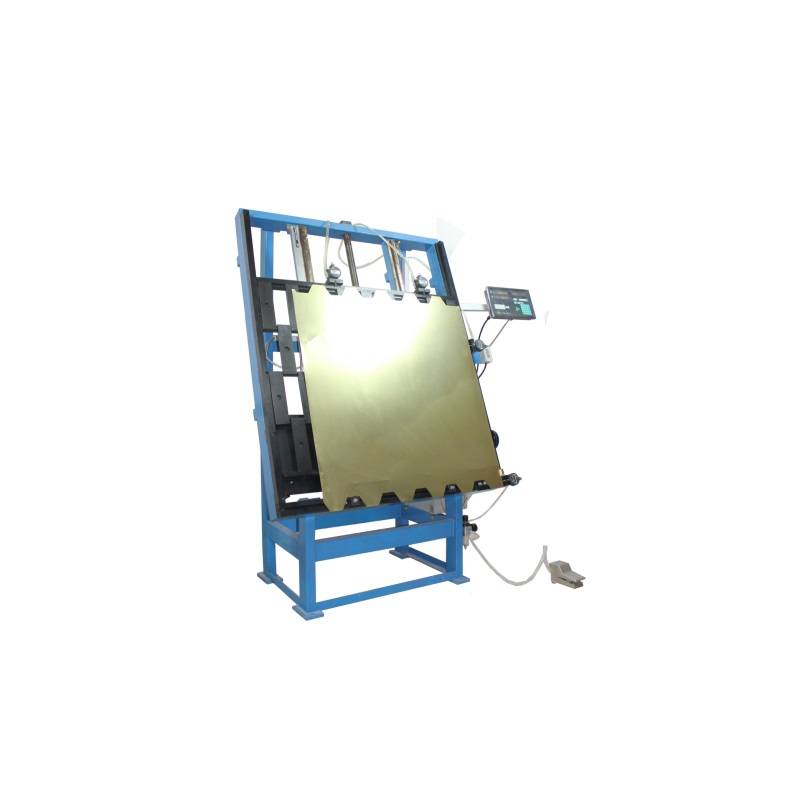

CanNeed-AEBT-1000 Automatic Buckle Tester for Loose ends

|

|

CanNeed-AEBT-1000 Automatic Buckle Tester for Loose ends is for testing the exact pressure at which the end buckles. Any end of varying diameter can be tested: change parts are available that can be exchanged within seconds. Three testing modes: “Buckle Test”, “Missile Test”, and “Score Burst Test”. If configured with special clamp, it can make score line cracking test for an end. Suitable for ends of various sizes. User should choose the clamp accordingly.

|

|

|

CanNeed-ADER-E1000 Automatic Digital Enamel Rater for Ends

|

CanNeed-ADER-E1000 is used to test the coverage of the enamel coating inside ends.(enamel coating compactness, mA)

ADER-E1000 automatically place the end into measuring station, then get the current value (mA)of the end after 4 seconds, and also display Max current value and average current value at the same time. If any failure in test caused by poor contact, there will be a reminder and warning. Data can be output to PC via RS 232 C interface.

ADER-E1000 can detect the exposed metal quicker with optimized electric design to make test quicker, more reliable and accurate.

|

|

|

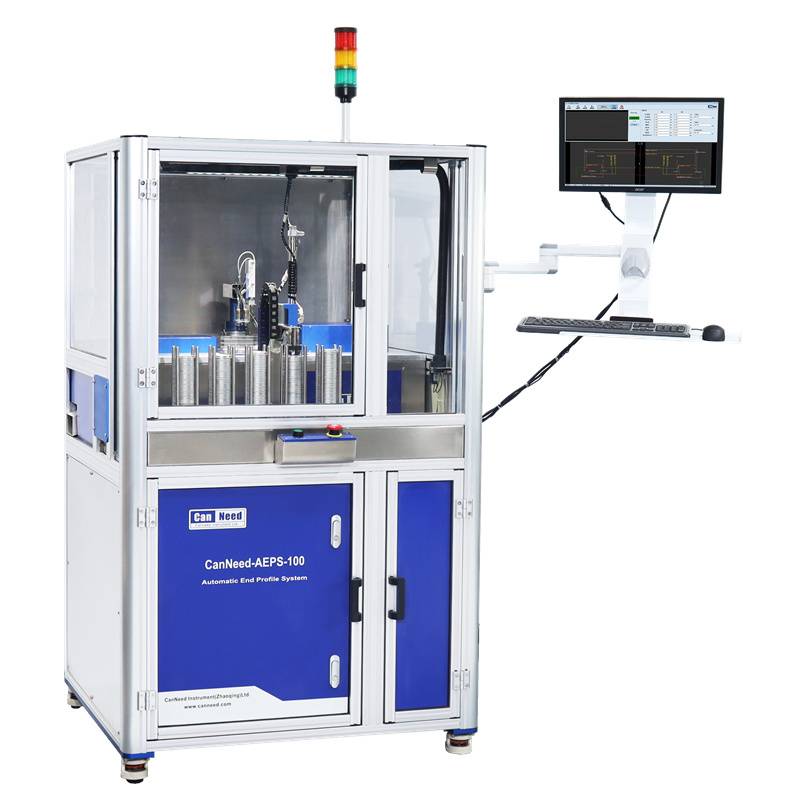

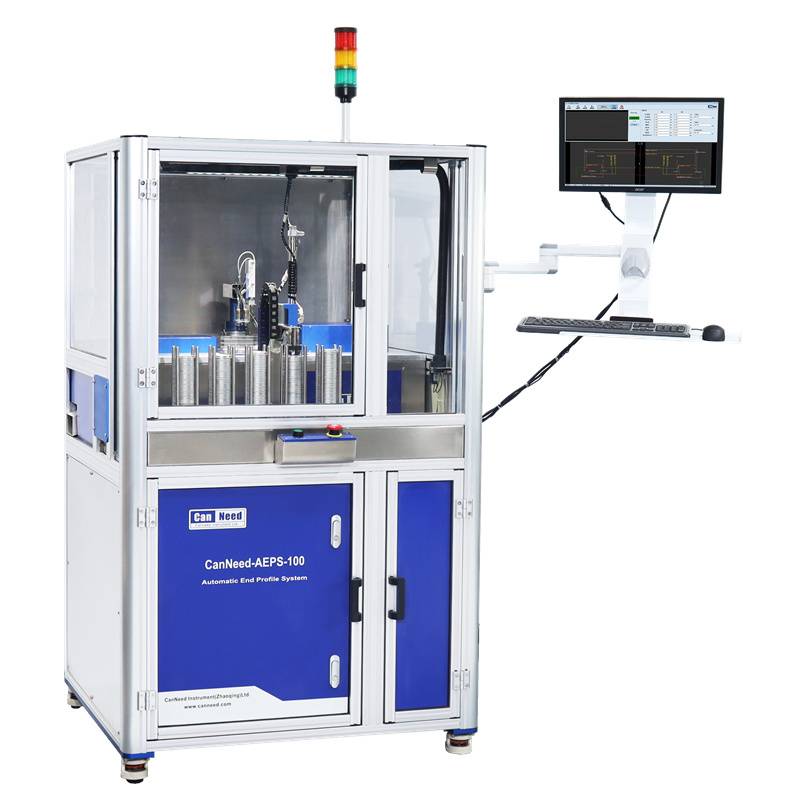

CanNeed-AEPS-100 Automatic End Profile Systems

|

CanNeed-AEPS-100 Automatic End Profile System is used to measure the end dimensions. It is with excellent performance by adopting precise optics measuring technology, measuring the end dimensions precisely.

The inaccuracy of end dimensions usually cause to such double seam defects as fault sealing, bearing cover and false sealing and so on. It is hard to measure the profile dimensions of ends without CanNeed-AEPS-100.

CanNeed-AEPS-100 takes the place of destruction measuring methods. The destruction measuring methods are not only inaccurate and time-consuming, but also get different results because of different operators.

Adopting precise optics measuring technology, CanNeed-AEPS-100 can measure all important parameters of ends.

|

|

|

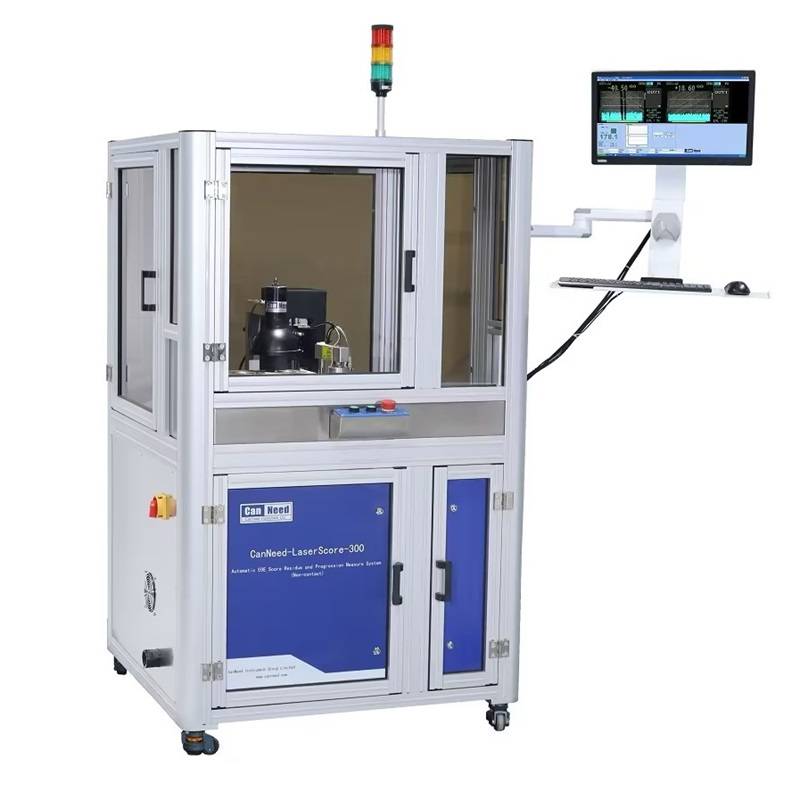

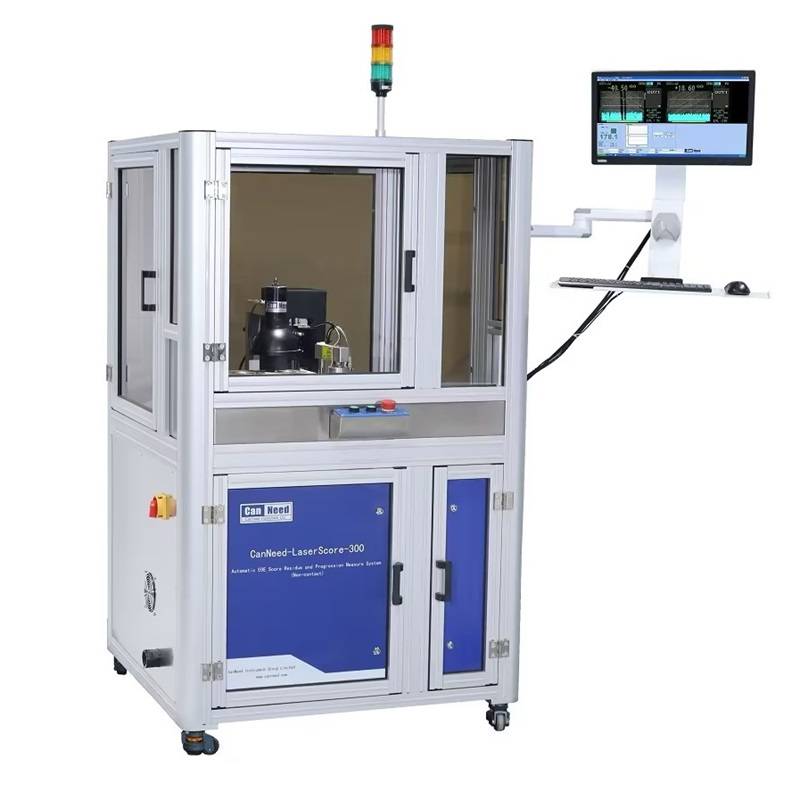

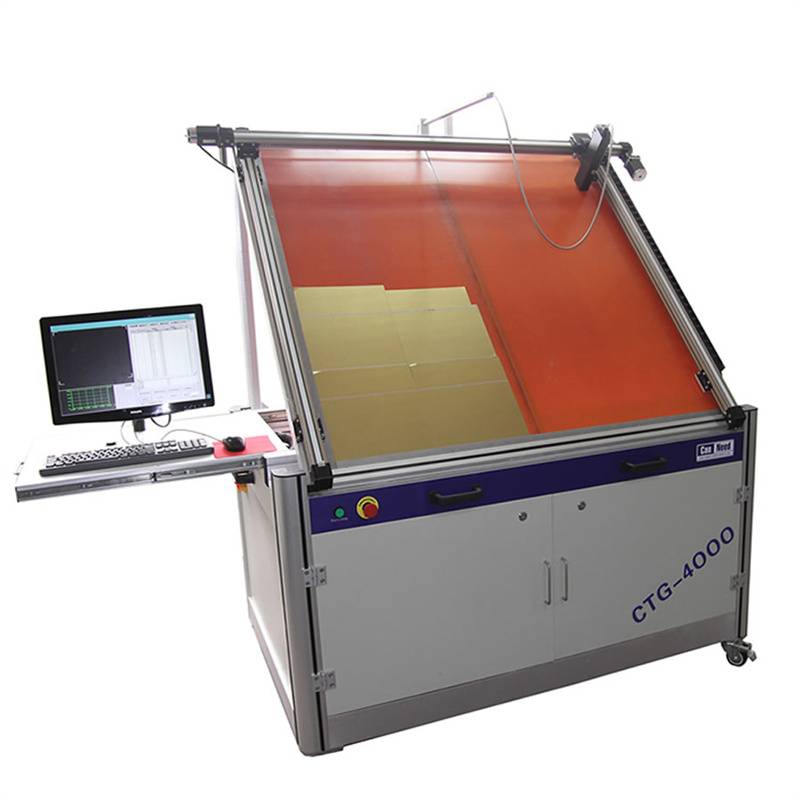

CanNeed-LaserScore-300 Automatic EOE Score Residue and Progression Measure System (Non-contact)

|

|

Based on laser technology and automatic visual positioning technology, the CanNeed “LaserScore-300 Automatic EOE Score Residue and Progression Measure System” is used to inspect EOE score residue and rivet convex progression automatically. LaserScore-300 has 2 work positions, each position adapts to inspect 202, 206 and 209 EOE.

Put several EOE samples stacked in the position to be measured, when testing, the automatic sampling mechanical arm will send the sample to the inspection clamp, the servo system coordinate with the automatic visual positioning system, positioning the measuring point accurately, measuring the different points on EOE by turns, the automatic sampling mechanical arm will send the sample from the clamp back to the stacked position after inspection completely each time.

The application of LaserScore-300 realizes automatic measuring batch samples, save time, labor and material greatly.

|

|

|

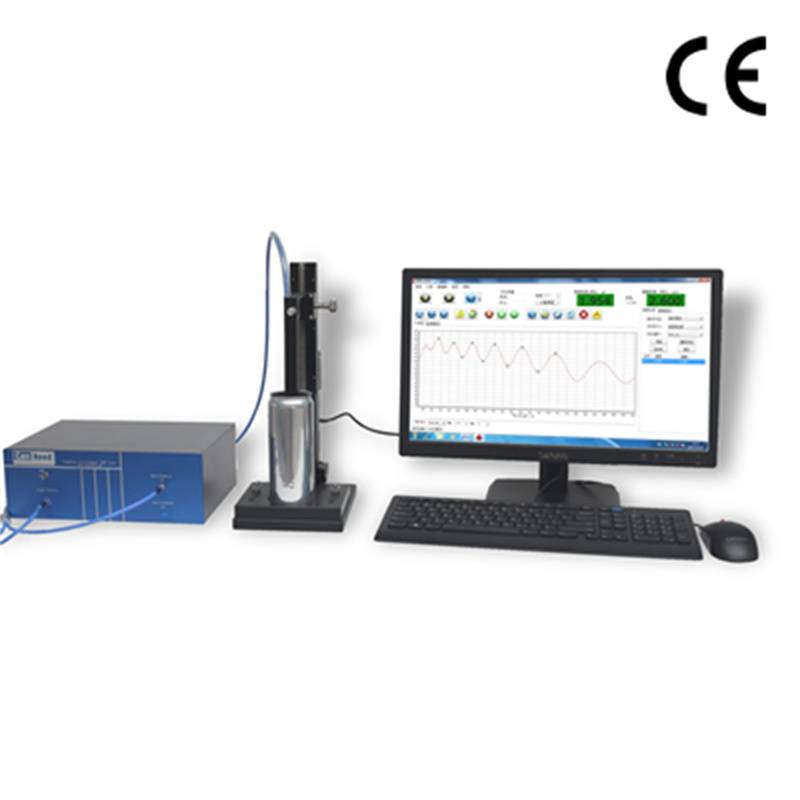

CanNeed-LaserScore-200 Score Residue Measure System

|

|

Based on laser technology and software analysis, the “CanNeed-Laserscore-200 Score Residue Measure System” is a non-destructive system for measuring the residual score on Ends. It combines ease of use and reliability with excellent repeatability and accuracy. The end clamp is equipped in a 360° rotary two-dimension linear guide working platform. It matches the ends, convenient to position and measure.

Measure principle: The position of reflected light on the sensor changes corresponding to the change of

"the score depth”. Through inspecting this position change, it can measure the score depth of ends. The CanNeed-LaserScore-200 system uses two laser sensors, which are installed on the top side and underside of the can end – the reflect Laser beam to the sensors depending on the depth of the surface. The score depth and residue are calculated based on the calibration table and the actually performed measurement.

It takes about 5 seconds to do a measurement. It is simple to operate the laser measure software!

|

|

|

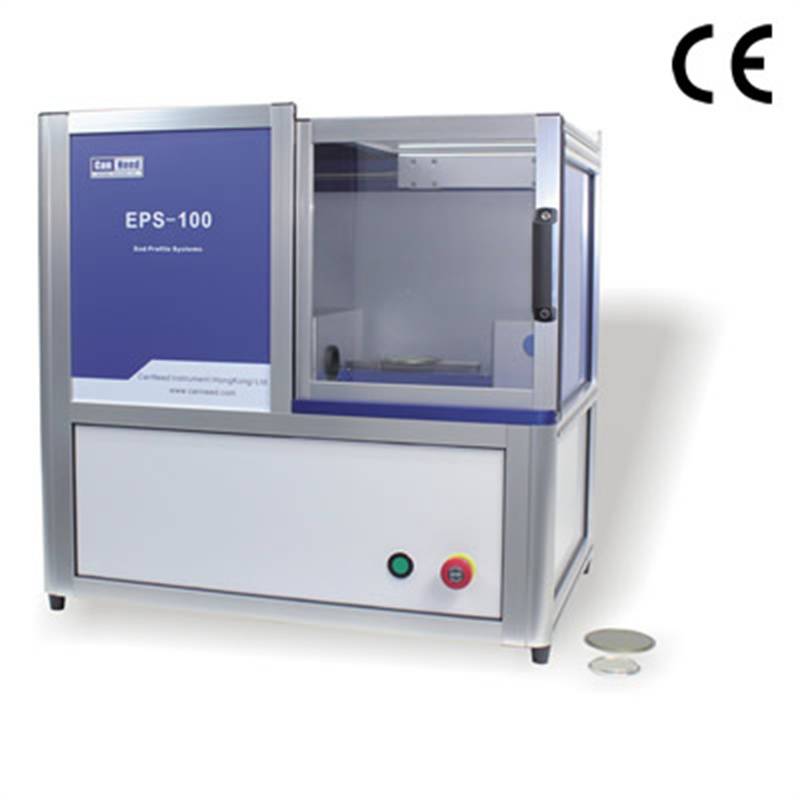

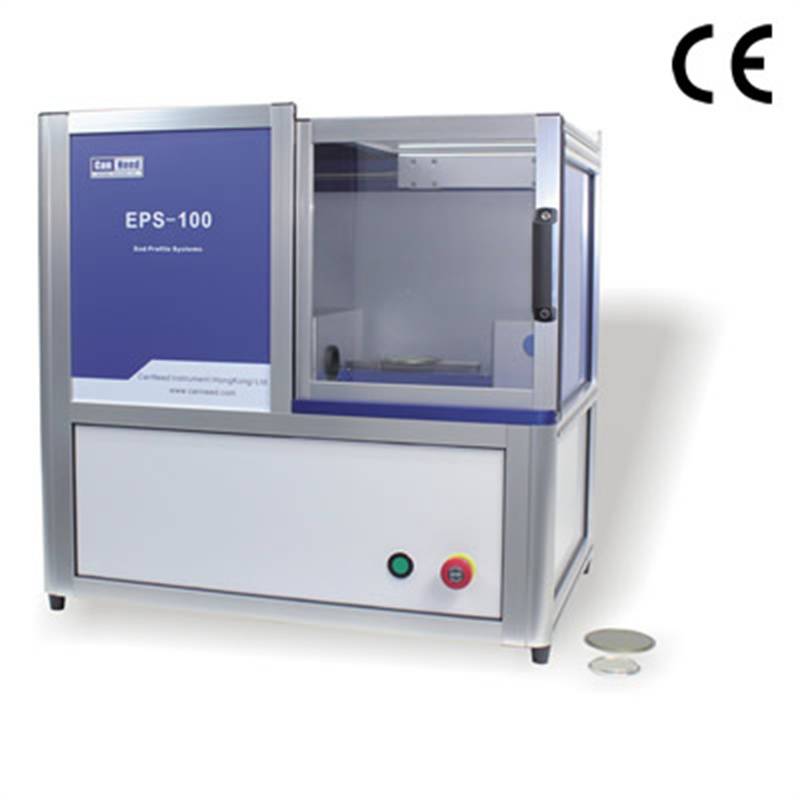

CanNeed-EPS-100 End Profile System

|

|

CanNeed-EPS-100 End Profile System is used to measure the end dimensions. It is with excellent performance by adopting precise optics measuring technology, measuring the end dimensions precisely.

The inaccuracy of end dimensions usually cause to such double seam defects as fault sealing, bearing cover and false sealing and so on. It is hard to measure the profile dimensions of ends without EPS-100.

EPS-100 takes the place of destruction measuring methods. The destruction measuring methods are not only inaccurate and time-consuming, but also get different results because of different operators. Adopting precise optics measuring technology, EPS-100 can measure all important parameters of ends.

|

|

|

CanNeed-DT-100 Thread Depth Gauge

|

|

CanNeed-DT-100 Thread Depth Gauge is used to measure the thread depth on the caps of aluminum bottle cans, which can make the bottle can closure fit better with the caps.

The gauge assembles with a digital Mitutoyo meter and a calibration platform.

|

|

|

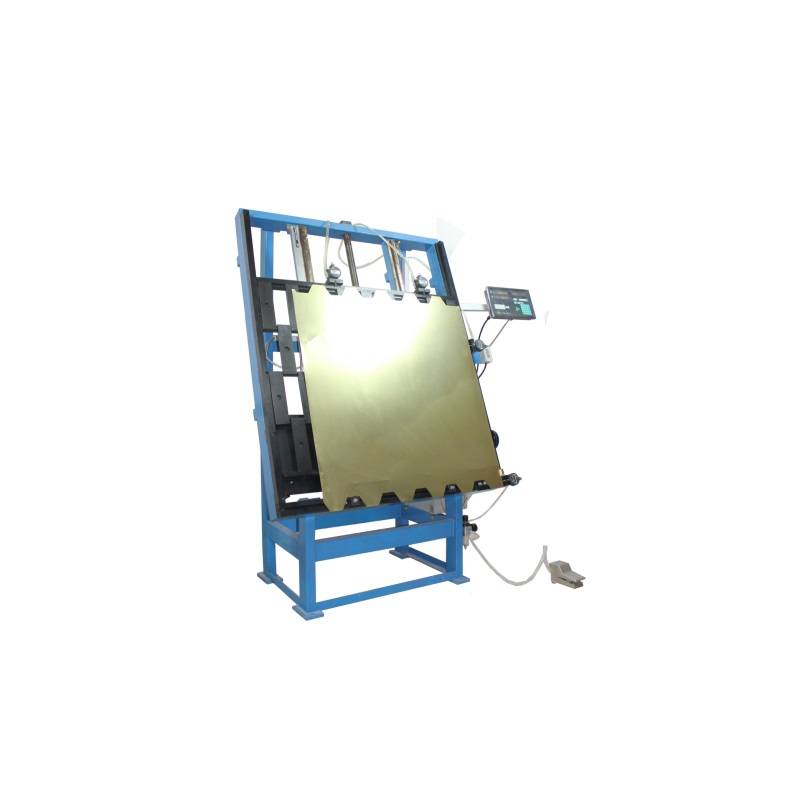

CanNeed-EPS-200 End Profile System

|

|

CanNeed-EPS-200 End Profile System is used to measure the end dimensions. It is with excellent performance by adopting precise optics measuring technology, measuring the end dimensions precisely.

CanNeed-EPS-100 adopts precise optics measuring technology, takes the place of destruction measuring methods. The destruction measuring methods are not only inaccurate and time-consuming, but also get different results because of different operators. The inaccuracy of end dimensions usually cause to such double seam defects as fault sealing, bearing cover and false sealing and so on. With CanNeed-EPS-200 End Profile System, it can easily measure the entire profile parameters of ends.

|

|

|

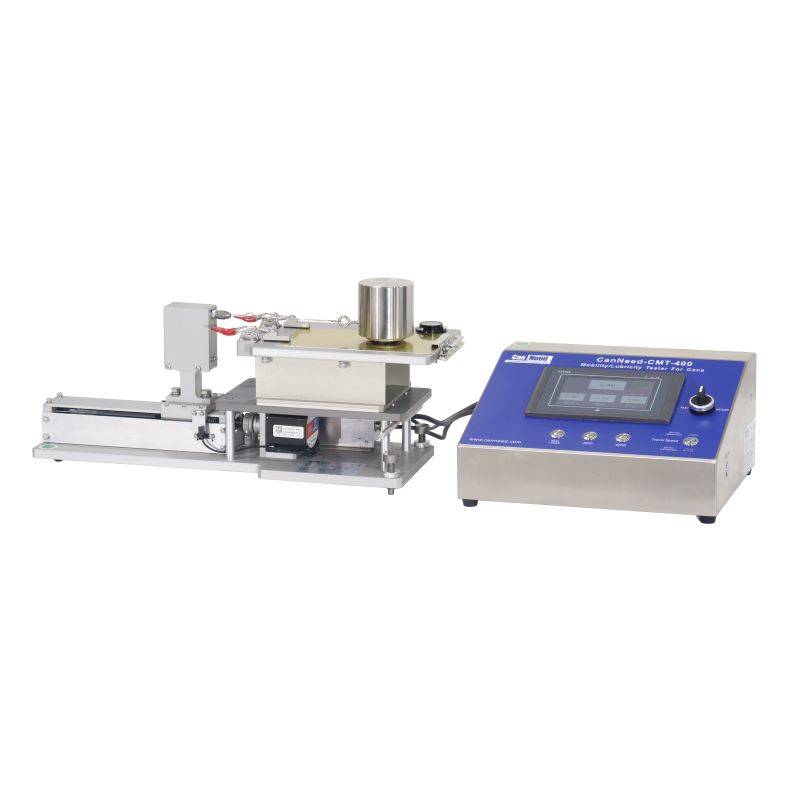

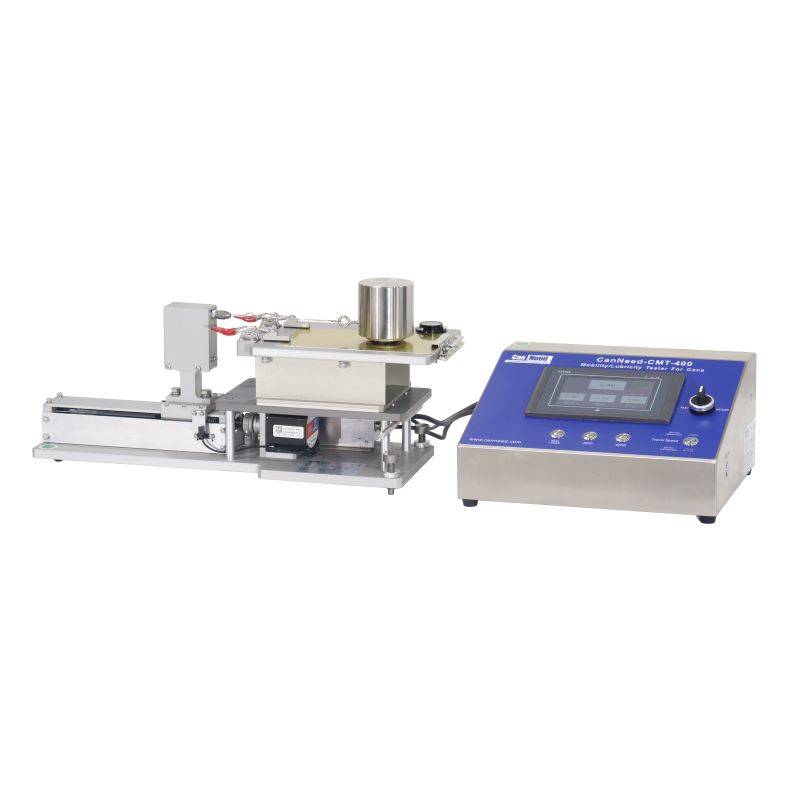

CanNeed-CMT-400 Mobility / Lubricity Tester for Cans (Digital)

|

|

CanNeed-CMT-400 Mobility / Lubricity Tester for Cans is for measuring the coefficient of sliding friction of can body and bottom. It can also measure the coefficient of sliding friction of blanks.

|

|

|

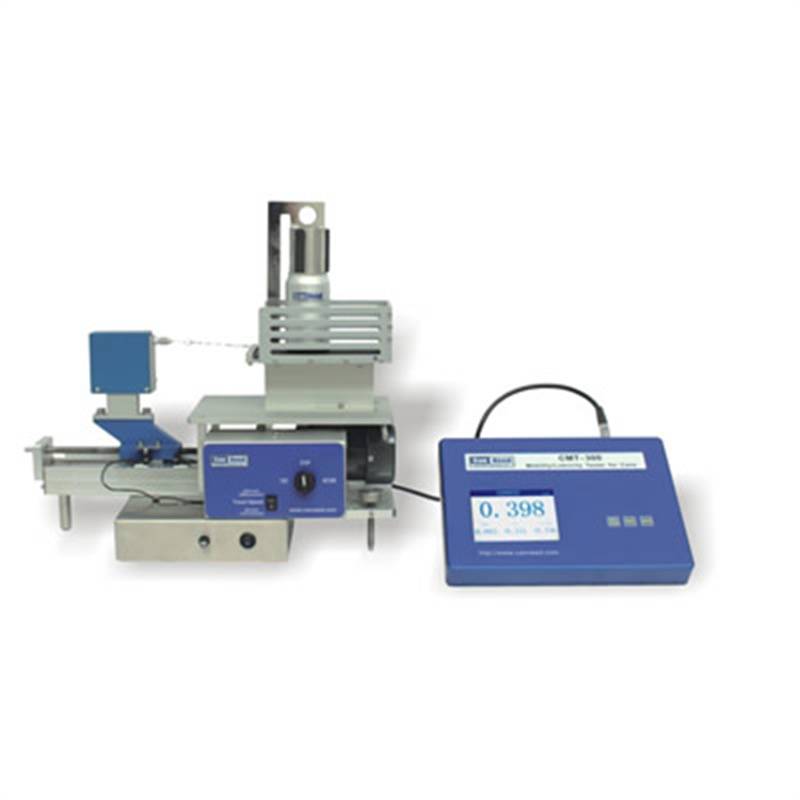

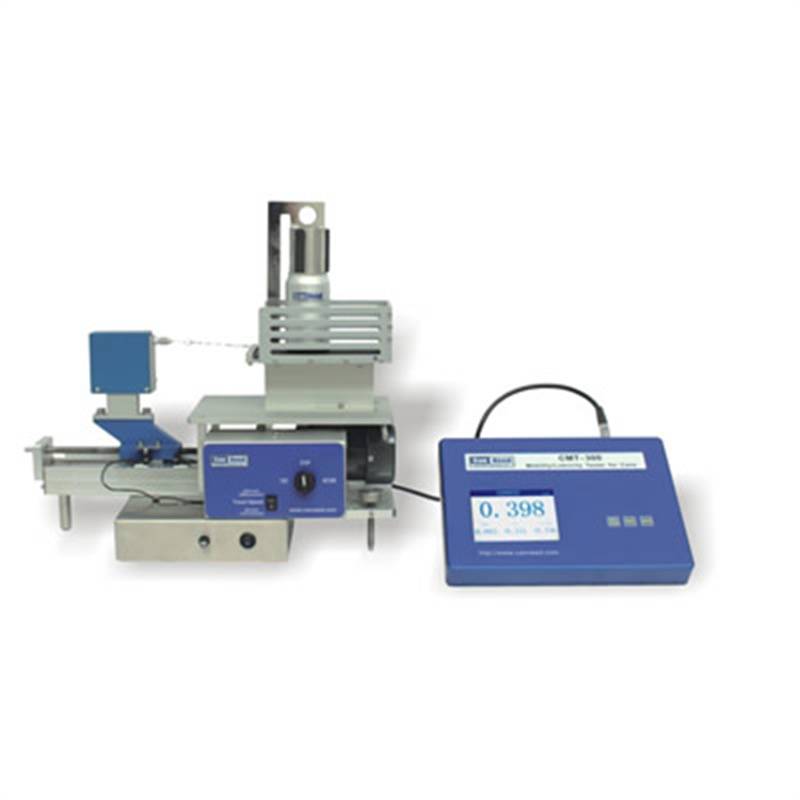

CanNeed-CMT-300 Mobility/Lubricity Tester for Cans (Digital)

|

|

CanNeed-CMT-300 Mobility / Lubricity Tester for Cans is for measuring the coefficient of sliding friction of can body and bottom. It can also measure the coefficient of sliding friction of blanks.

Install the corresponding clamp and place the sample on the clamp, then put the bob-weight unit on the sample. Pull the bob-weight and the indicator will display the coefficient of sliding friction.

|

|

|

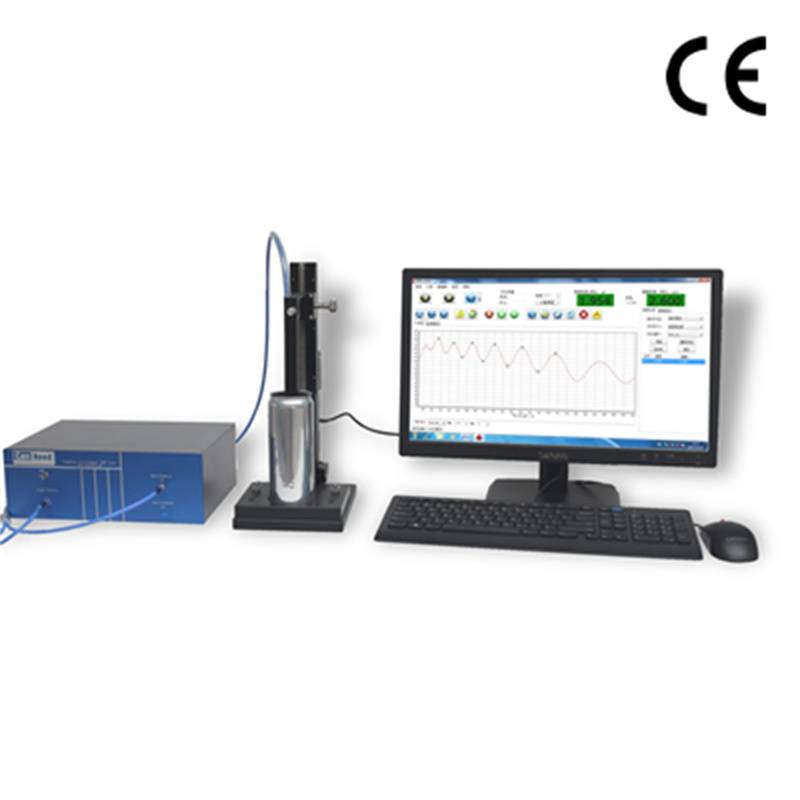

CanNeed-OCTG-2000 Coating Thickness Gauge

|

|

CanNeed-OCTG-2000 Coating Thickness Gauge is used to measure the coating thickness in real time, save time and improve the quality of the product. Non-contact optical measurement technology is applied to product development, laboratory quality control and online production control. In the solar energy industry, optical coating industry, food packaging,as well metal packaging, are very good choice to improve the surface quality of products: appearance, adhesion, corrosion resistance, abrasion resistance, scratch resistance.

|

|

|

CanNeed-OCTG-1000 Optical Coating Thickness Gauge

|

|

CanNeed-OCTG-1000 Coating Thickness Gauge is used to measure the coating thickness in real time, save time and improve the quality of the product. Non-contact optical measurement technology is applied to product development, laboratory quality control and online production control. In the solar energy industry, optical coating industry, food packaging,as well metal packaging, are very good choice to improve the surface quality of products: appearance, adhesion, corrosion resistance, abrasion resistance, scratch resistance.

|

|

|

CanNeed-FSF-100 Tinplate Holder

|

|

The CanNeed FSF-100 Tinplate Holder is used together with the CanNeed-DER-400 Digital Enamel Rater and the vacuum device to test the integrality of the enamel coating inside the tinplate.

|

|

|

CanNeed-PTT-300 Pop & Tear Tester

|

|

CanNeed-PTT-300 Pop & Tear Tester was developed for testing different kinds of easy open ends. It can measure the Pop & Tear force, ring rotary force and ring detaching force.

Adopted 7 different testing modes: RP / SOT / EO / OVAL / SNAP / RF and RPP. OVAL mode can test both OVAL and FSE ends. SNAP mode can test both SNAP and ALUFIX ends. VF mode is for ring rotary force measurement while RPP mode is for ring detaching force measurement.

Applicable to various types of ends, here to be shown 7 types: RP / SOT / EO / OVAL / FSE / SNAP and ALUFIX. It’s also suitable for sample ends from types of 113 to 211 (round ends). Oval or rectangular ends needs customized clamp for test. Oval ends diameter or longer length of rectangular should not be longer than 163 mm.

|

|

|

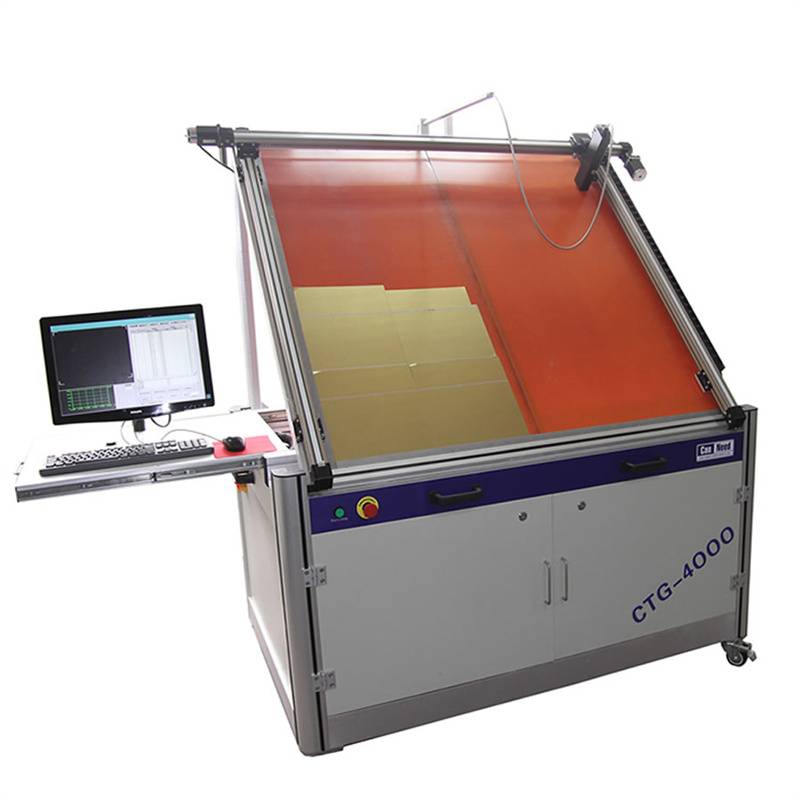

CanNeed-OCTG-4000 Thickness Gauge and Wet Film Thickness

|

|

Measure real-time thickness of coating and welt film.Save time and improve quality

Deliver real-time results on single or dual layers

Adopt non-contact optical technology,applicable for R&D,QC,and on-line production

In solar energy,optical filming,food packaging and metal packaging industries, improve surface quality such as appearance, adhesion, corrosion resistance, wear resistance, and scratch resistance.

|

|

|

CanNeed-TT-200 Torque Tester

|

Applications: Food-industry / Cosmetic/ Pharmaceutical / Chemical / Metrology

CanNeed-TT-200 Torque Tester is a professional equipment which is used to test the caps’ “capping torque”and “songaila torsion “for bottled products.It is industry standard with excellent performance.Users can option software.

|

|

|

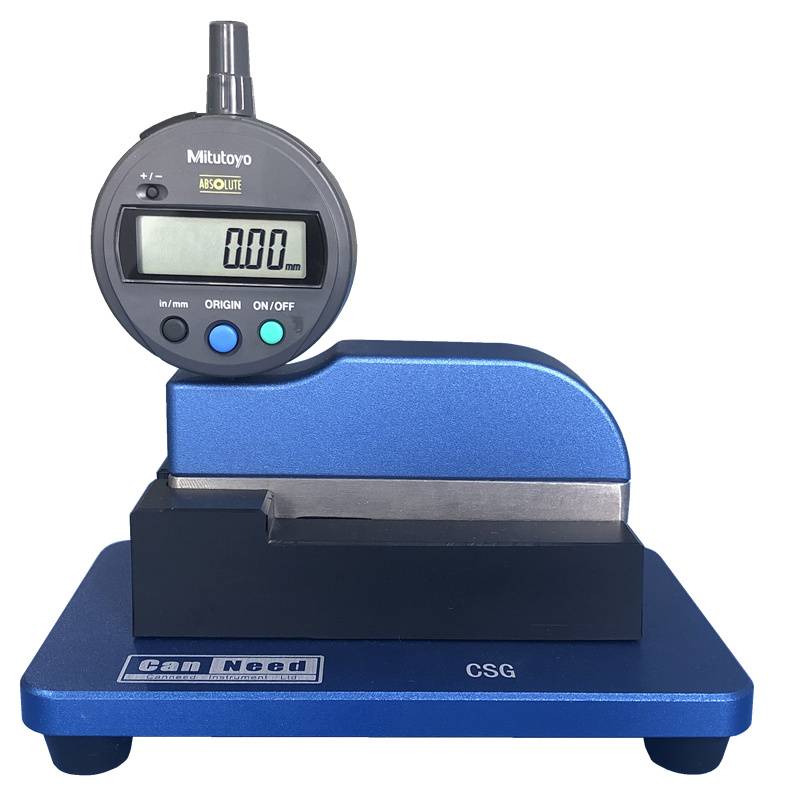

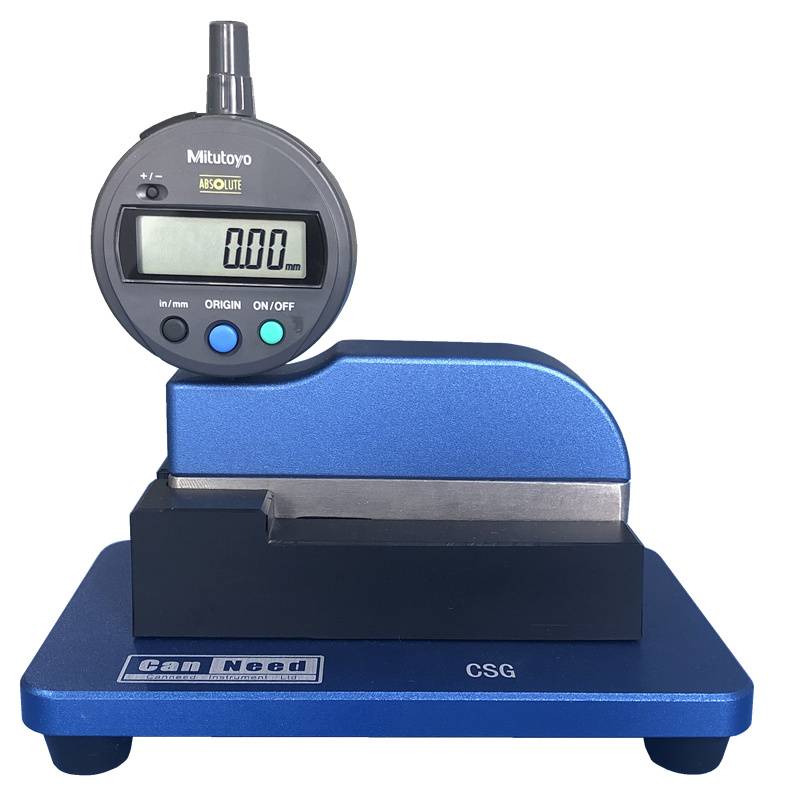

CanNeed-CSG-200 Countersink Gauge (Digital)

|

|

The CanNeed-CSG-200 Countersink Gauge (digital) is a Digital gauge for measuring Countersink depth parameters (the depth of beader of can). With the Mitutoyo 0.01mm Resolution Digital Indicator.

The gauge can be connected to a computer or SPC system via the adapter and cable, so that to avoid the manual recording and personal error. The gauge can also combine with Canneed Seam Monitors and import the measurement data into computer.

|

|

|

CanNeed-MDER-10 Multi-station Digital Enamel Rater for Ends

|

|

CanNeed-MDER-10 Multi-station Digital Enamel Rater For Ends is used to test the integrity of the inner coating (inner coating density and current value) of the 10 ends at one time. If the inner coating is incomplete and the contents will corrode the metal and affect the quality and storage of the product.

Place ends into the opening hole of ten-hole fixing holders. After the ends are pressed, turn the ten-hole fixing holders over. The current values (mA) of each end as well as the maximum current value and average value can be read out in 4 seconds. If any test failure resulted from bad connection between the contacts, the corresponding position number of the ends will be shown on the screen.

|

|

|

CanNeed-DER-400 Digital Enamel Rater

|

|

CanNeed-DER-400 Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

CanNeed-DER-400 is the industry standard. The new CanNeed Enamel Rater DER-400 instrument test the coverage of the enamel coating inside food and beverage cans, aerosol-cans and also different kinds of ends. It displays an index of the amount of metal exposed by incomplete enamel coverage on a clear, easily read digital LED.

|

|

|

CanNeed-DER-4 Digital Enamel Rater

|

|

The CanNeed-DER-4Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

CanNeed-DER-4 is the industry standard. The new CanNeed-DER-4Enamel Rater instrument test the coverage of the enamel coating inside food and beverage cans, aerosol-cans and also different kinds of ends. It displays an index of the amount of metal exposed by incomplete enamel coverage on a clear, easily read digital LED.

|

|

|

CanNeed-ZME-1220 Digital End Blank Gauge for Scroll Cut

|

CanNeed-ZME-1220 is to measure the following items of the end blank:

1. Length

2.Parallelism

3. Perpendicularity (angle)

4.Reference points

|

|

|

CanNeed-BDD-200A Bead Depth Gauge

|

|

CanNeed-BDD-200A Bead Depth Gauge is for measuring the bead depth of the can body, with the special designed end measuring holder, end bead depth can also be measured. The fine designed can holder, which ensures the cans keep still during the measuring, and the results are more accuracy.

|

|

|

CanNeed-SMM-400 Score Measure Microscope

|

|

CanNeed-SMM-400 Score Measure Microscope adopted the microscope technology to measure the score depth and residue of can ends. The measurement is accomplished by the focusing of microscope, if the microscope gets a very clear image, that means the focusing is correct, the height changing of the focus of microscope shows the depth of the end score. The diameter of nether measuring needle is very small, focusing on the top of the nether measuring needle, zero the indicator, place the sample end onto the platen, adjust the focus until gets the clear groove bottom image of the end score, then gets the score residue. Place the sample onto the platen, focusing on the surface of sample ends (edge of the score), zero the indicator, adjust the focus , when the clear groove bottom image displays on the screen, then gets the depth of score.

|

|

|

CanNeed-PTT-400 Pop & Tear Tester

|

|

CanNeed PTT-400 Pop & Tear Tester was developed for testing different kinds of easy open ends. It can measure the Pop & Tear force, ring rotary force and ring detaching force.

Applicable to various types of ends, here to be shown 7 types: RP / SOT / EO / OVAL / FSE / SNAP and ALUFIX. It’s also suitable for sample ends from types of 113 to 603 (round ends). Oval or rectangular ends needs customized clamp for test. Oval ends diameter or longer length of rectangular should not be longer than 163 mm.

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|